Guide needle holder and guide needle device

A technology of guide needle and retainer, which is applied in the direction of knitting, warp knitting, textile and papermaking, etc., to achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

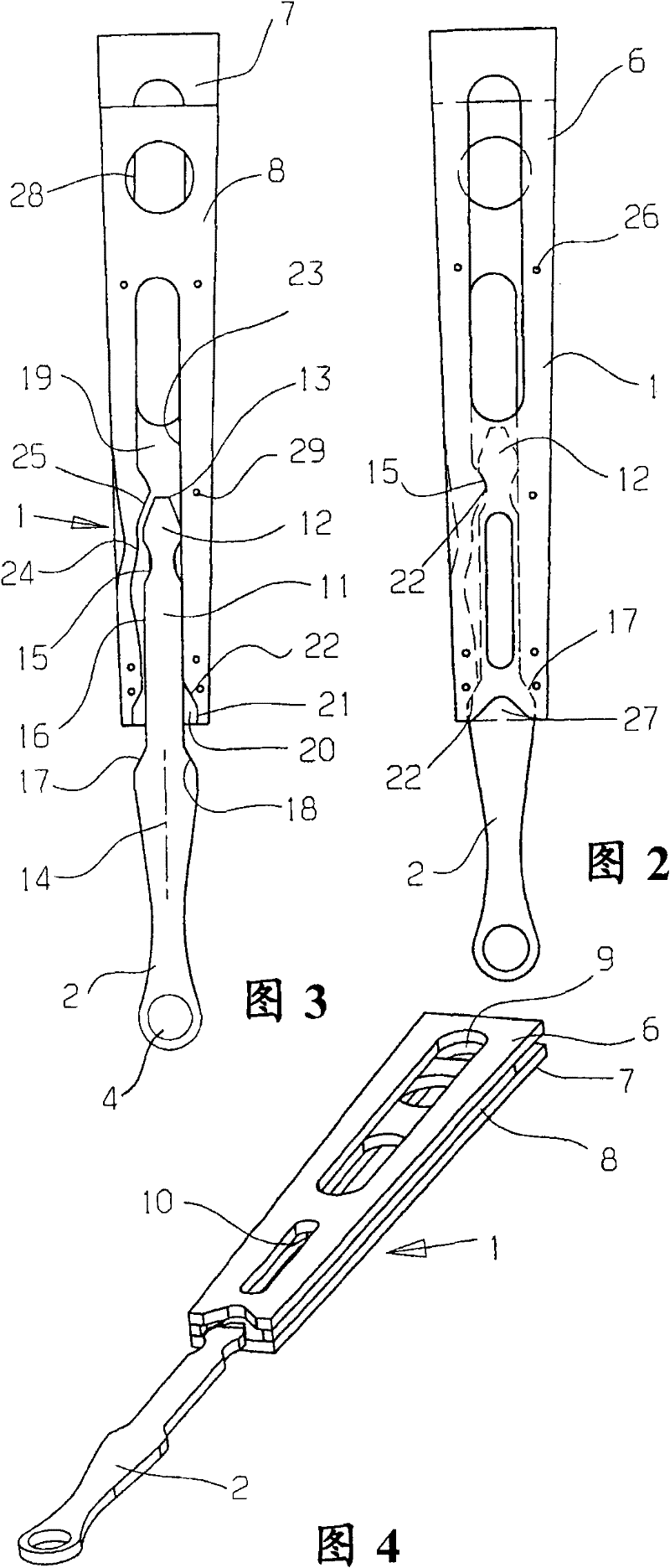

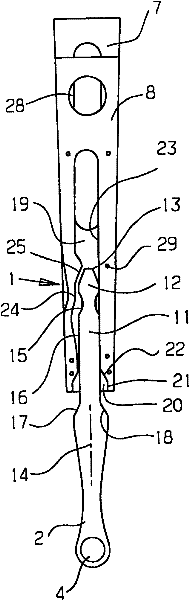

[0030] figure 1 The yarn guide needle holder 1 with the yarn guide needle 2 is shown. The guide needle 2 has a first end 3 in which a hole 4 is provided through which the warp thread is guided when it is loaded into the warp knitting machine, and then the warp thread passes through the guide needle 2 and is not further processed. The knitting needles are shown undergoing a knitting process.

[0031] At its end remote from the yarn guide needle 2, the yarn guide needle holder 1 is connected to a piezoelectric element device 5, with which the yarn guide needle 2 can be moved in the traverse direction, that is, in the parallel Move in a direction extending through the axis of the hole 4.

[0032] as in Figure 4 As seen in , the guide needle holder 1 has a cover plate 6, a bottom plate 7 and an intermediate plate 8 therebetween. All three plates 6-8 have substantially the same material thickness and can therefore be stamped from the same sheet material. The intermediate plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com