Connecting member of socket and spigot type tenon-mortise self-locked steel pipe scaffold

A socket type, scaffolding technology, applied in the field of scaffolding, can solve the problems of poor stability and bearing capacity, easy loss of fasteners, etc., to achieve high bearing capacity, avoid loss, and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

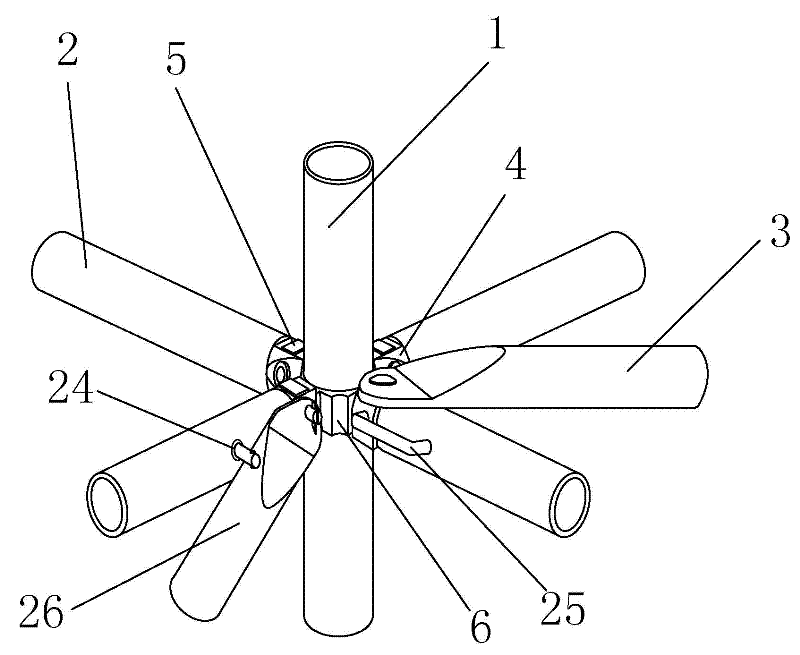

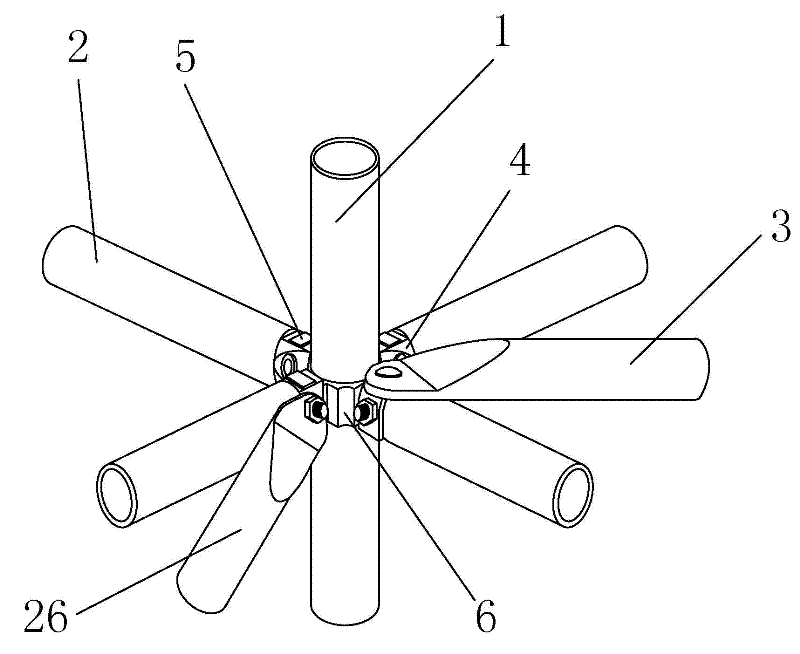

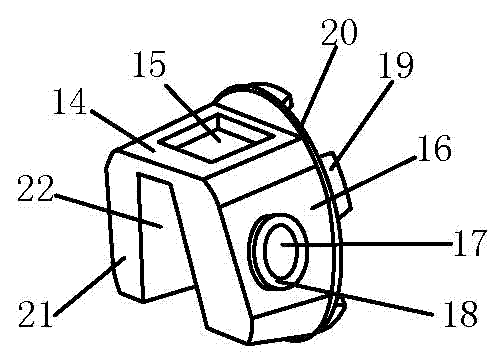

[0019] Depend on Figure 1-Figure 12 Given, the present invention includes a crossbar assembly, a standpipe and a vertical pole tenon socket. The crossbar assembly is composed of a crossbar 2 combined with a sliding pin 25 and a crossbar socket 4. One end of the sliding pin is mounted on the crossbar In the mortise, the other end is worn in the through hole 24 of the cross bar. The front end of the cross bar and the mortise of the cross bar are fixed together. The standpipe 1 is fixed in the tenon socket 6 of the vertical bar. The rod sockets 4 are fitted together, and the horizontal bar assembly is connected with the horizontal slanting bar assembly 3 and the vertical slanting bar 26 respectively. 11 The rivet 13 (bolt or pin) is connected with the slot 12, the horizontal slanting bar can rotate around the rivet (bolt or pin) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com