Tuyere tip for both an American tuyere and a French tuyere

A dual-purpose air nozzle head and American-style nozzle technology, applied in the direction of functional valve type, valve details, multi-way valve, etc., can solve problems such as looseness, large volume, and large operating space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

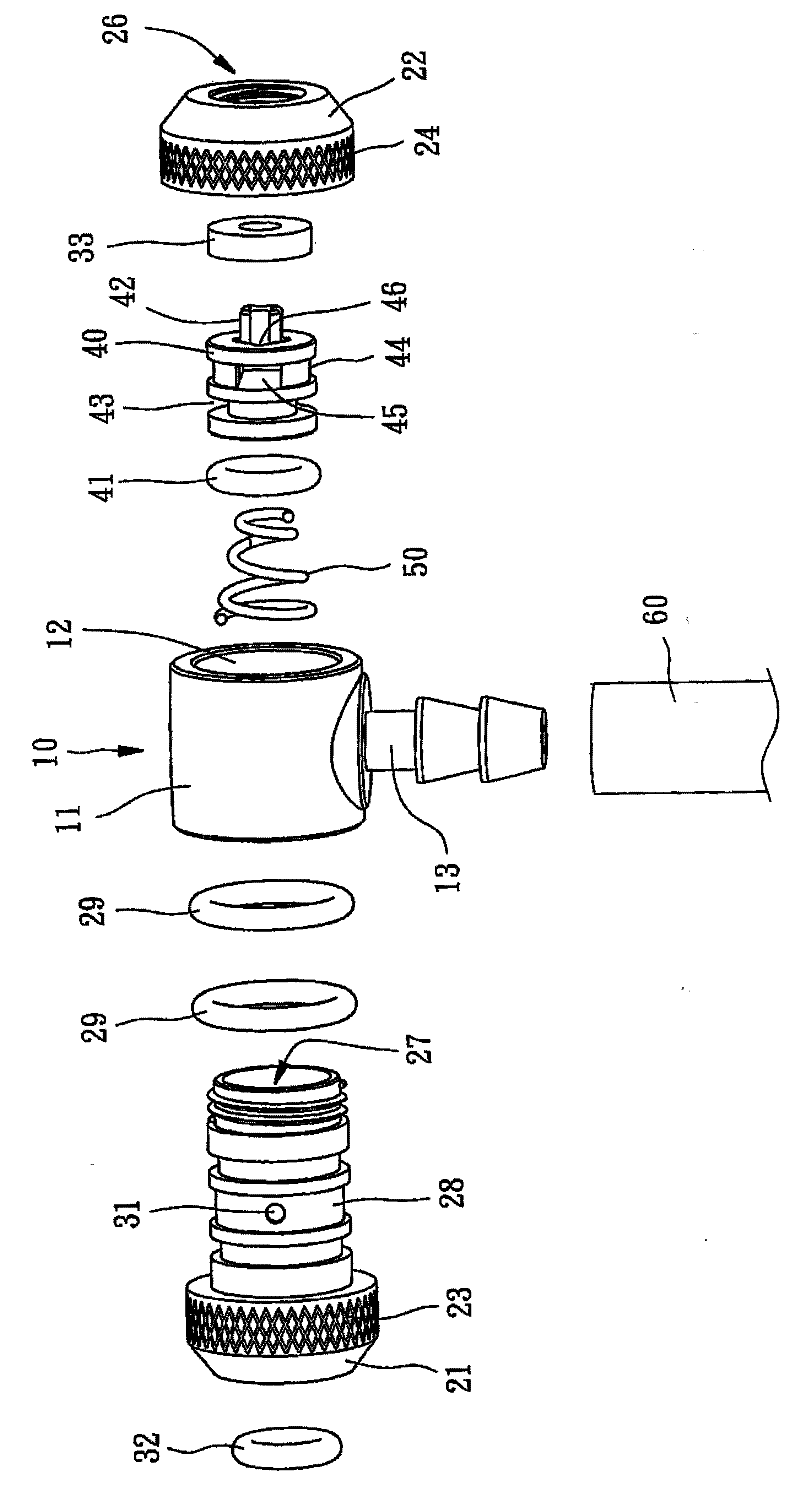

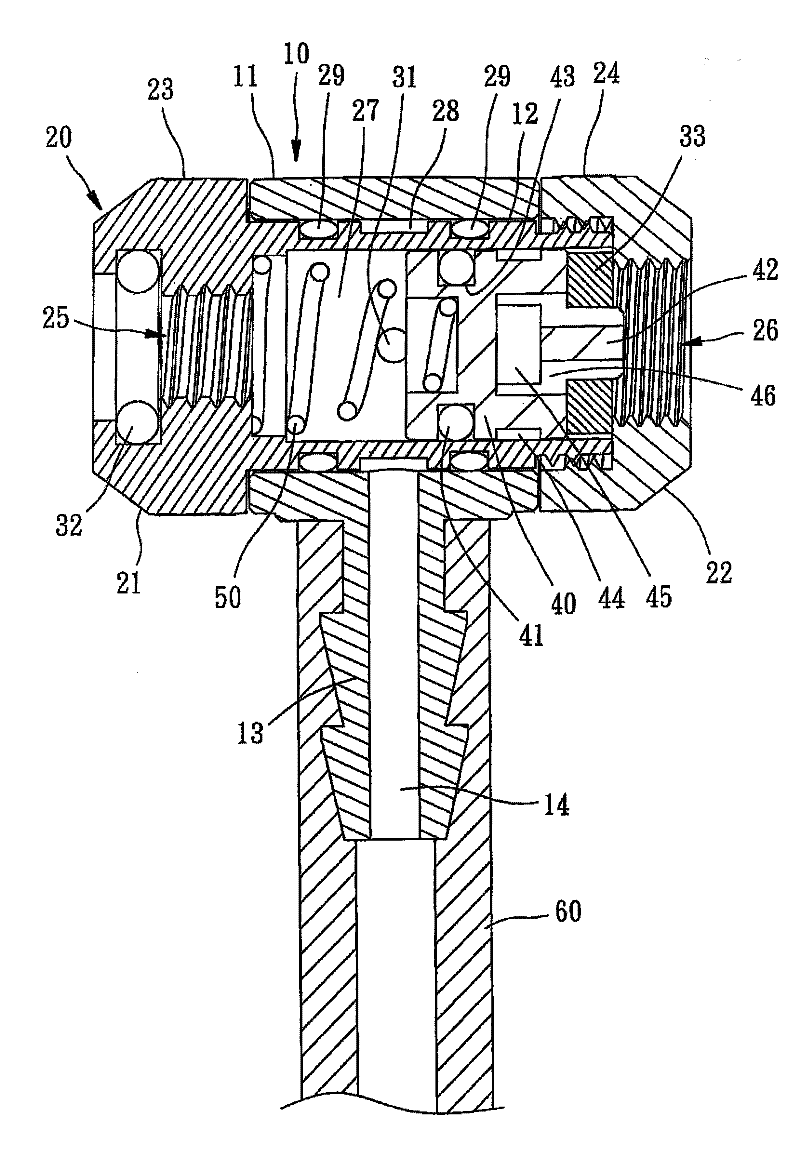

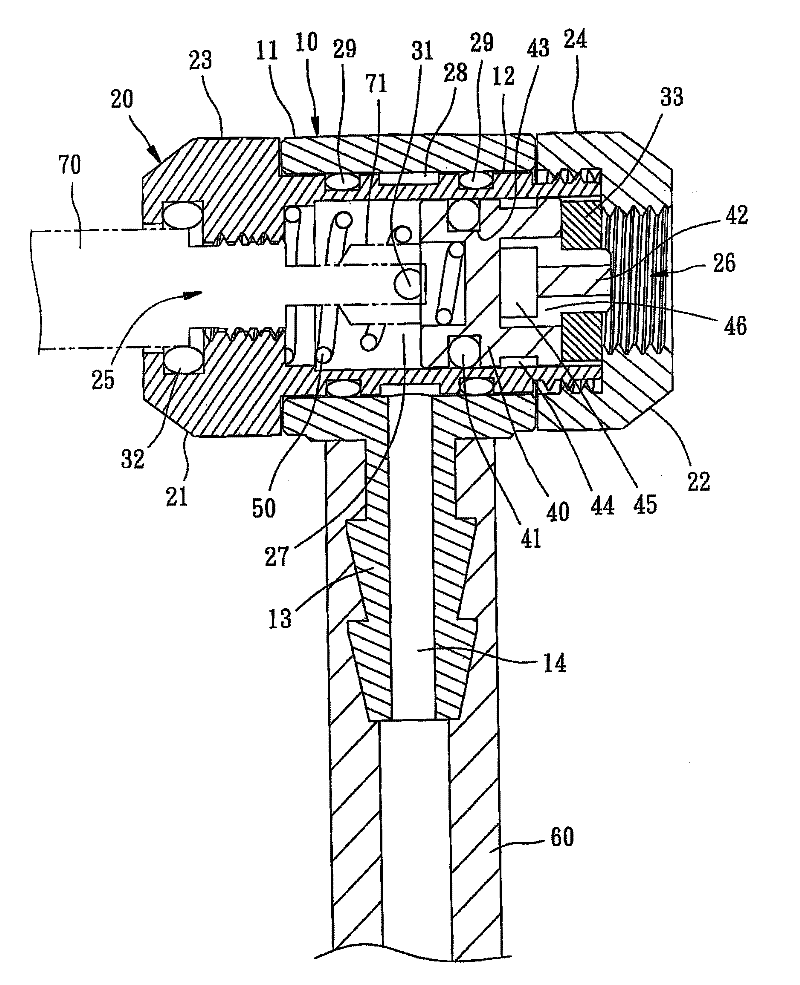

[0020] Such as figure 1 , figure 2 As shown, the American nozzle and the French nozzle dual-purpose nozzle head provided by the embodiment of the present invention include:

[0021] A casing 10 has a body 11 with a shaft hole 12 in the middle, and an end 13 extending outward from the side of the body 11 , and a through hole 14 communicated with the shaft hole 12 in the middle of the end 13 .

[0022] A rotating part 20 is accommodated in the shaft hole 12 of the body 11 of the housing 10 and can rotate. 23 and 24 are respectively provided with a screw connection hole 25, 26, wherein one screw connection hole 25 can be screw connected with a French mouth, and the other screw connection hole 26 can be screw connected with an American mouth. There is an accommodating space 27 between them, which communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com