Paste capable of reducing fatigue crack growth rate of metal material, and metal material coated with the paste

A metal material, fatigue cracking technology, used in metal processing equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of inability to protect the ingress of the slurry, the viscosity of the slurry, and the unclear alumina, etc. The effect of good fluidity, reduced progression speed, and excellent accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] The slurry of the present invention is produced, for example, by putting particles that reduce the rate of fatigue crack progression into a liquid, stirring it with a stirrer, and finally mixing it completely with a stirrer. In addition, this slurry can also be produced by other methods, as long as the method can mix the particles and the liquid.

[0045] In this case, it is preferable to use a particle having a hardness higher than that of the metal material on which the slurry is applied among the particles that reduce the rate of progress of the fatigue crack. In the present invention, a high-hardness substance means a substance with a small amount of deformation. Specifically, it means a substance that has a large Young's modulus and is difficult to generate elastic deformation, or various types of hardness represented by Vickers hardness or Shore hardness. Any value of hardness is large, and plastic deformation is difficult to occur. The material of the particles ...

Embodiment 1

[0051] Alumina is used as the particle to reduce the fatigue crack progress rate, and a liquid with a viscosity of 5.5×10 is used as the liquid mixed with the particle. -2 Pa·s oil. By mixing these two, slurries (alumina slurries) of various viscosities are prepared.

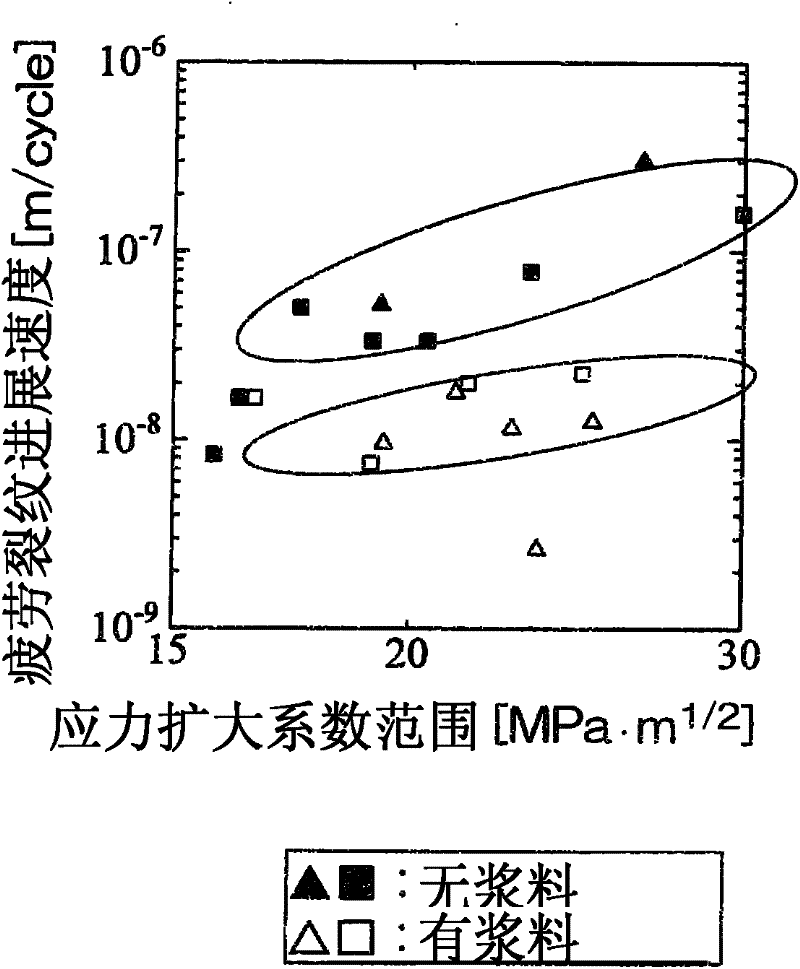

[0052] Hereinafter, the results when using a slurry with a viscosity of 32 Pa·s (particle diameter: 15.9 μm) and the results when not using a slurry will be described.

[0053] For 4 test pieces produced from the same batch of SS400 (JIS), 2 of them were coated with the above-mentioned slurry with a viscosity of 32 Pa·s, and the other 2 were not coated with the slurry, and loads were repeatedly applied to perform a fatigue test.

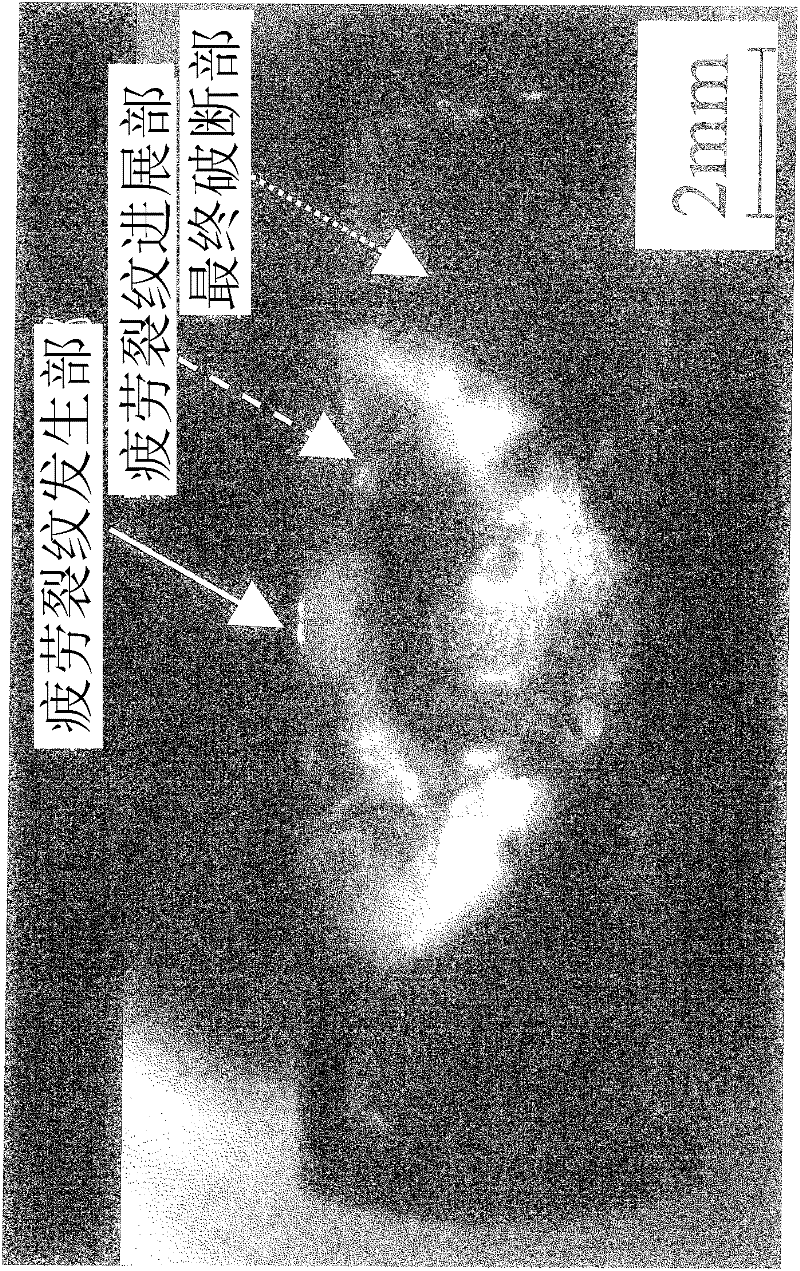

[0054] figure 1 It is an enlarged view (photograph) showing a fatigue cross section after a fatigue test. It can be seen that the slurry coated on the surface of the material enters the fatigue crack. Slurry with this viscosity can penetrate into the interior of fatigue cracks due ...

Embodiment 2

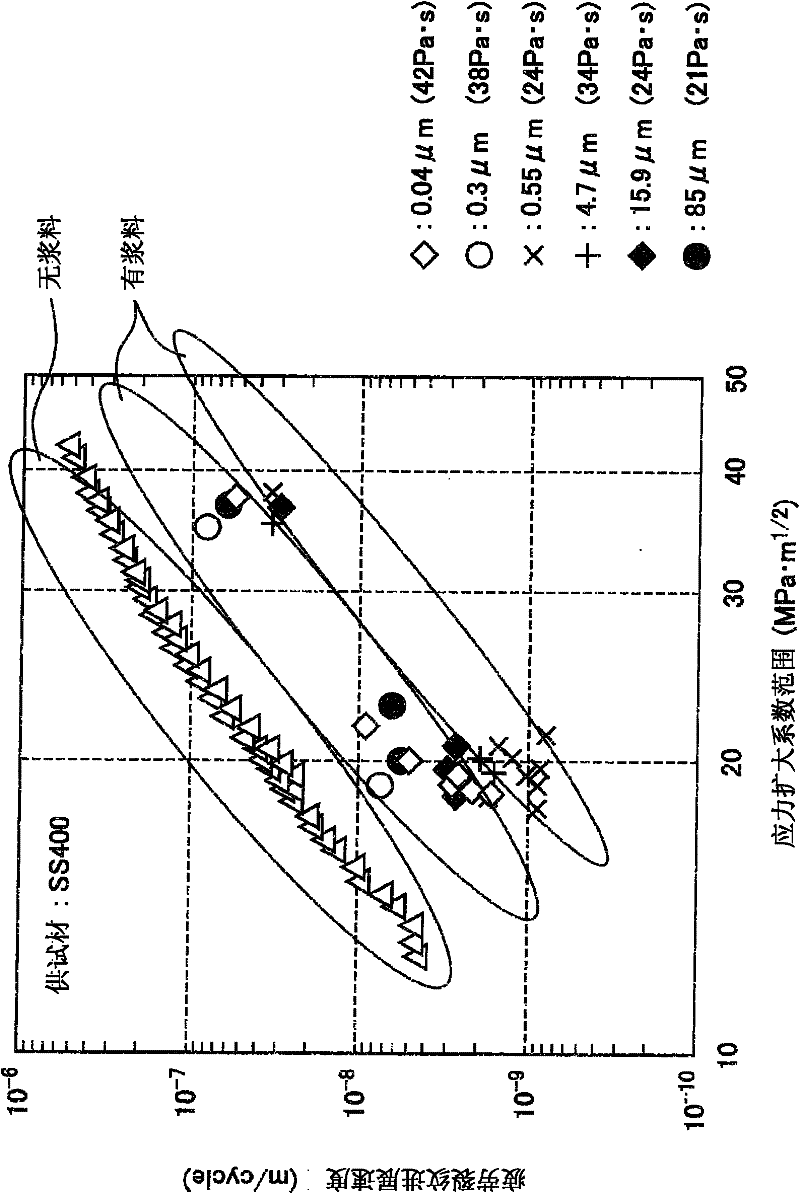

[0058] As the particles for reducing the fatigue crack progress rate, 15.9 μm alumina having the same particle diameter as in Example 1 above was used. In addition, as a liquid mixed with the particles, a viscosity of 1.2×10 -1 Pa·s turbine oil (turbine oil). By changing the amount of turbine oil when mixing the two, slurries (alumina slurries) of various viscosities were prepared. The viscosities of various slurries are 2.6Pa·s, 3.4Pa·s, 6.4Pa·s, 32Pa·s, 35Pa·s, 70Pa·s.

[0059] These slurries were applied to the same test pieces as in the above-mentioned Example 1 and subjected to a fatigue test to observe the cross-section after fatigue fracture to investigate the penetration of the slurries into the fatigue cracks. As a result, it was found that the intrusion into fatigue cracks was confirmed in any of the slurries, and that the use of these slurries can be expected to reduce the rate of progress of fatigue cracks.

[0060] At this time, the slurry with a viscosity of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com