Ham sausage ordering and conveying device

A conveying device and ham sausage technology, which is applied in packaging, sausage production, slaughtering, etc., can solve the problems of unrealized mechanized automatic packing, backward ham sausage automatic packing technology, and no substantive breakthrough, and achieve improved sorting and conveying Efficiency, high degree of automation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

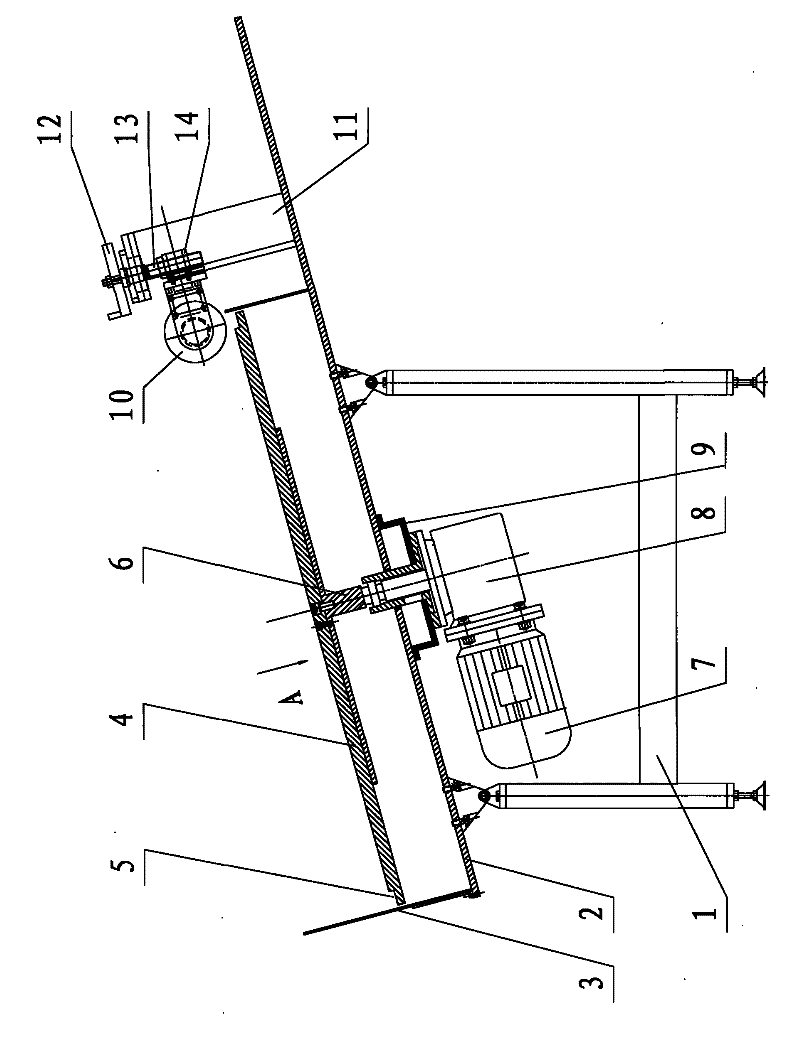

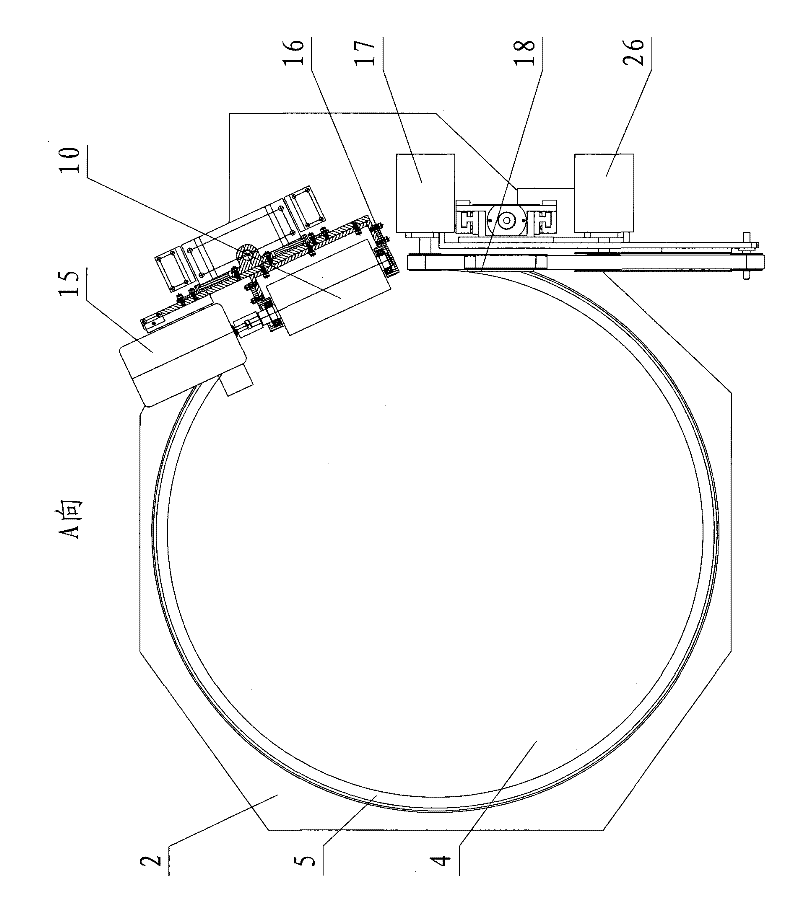

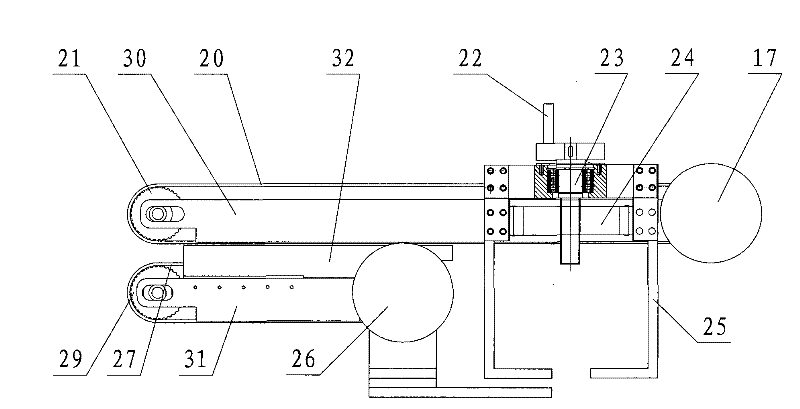

[0021] like figure 1 , figure 2 As shown, the present invention includes a support 1, a fixed plate 2, a shroud 3, a turntable 4, a drive mechanism for driving the turntable 4 to rotate, a height-adjustable brush roller mechanism, and an up and down horizontal acceleration belt mechanism, wherein the drive mechanism includes a first transmission Motor 7, reducer 8, motor base 9 and connecting shaft 6, brush roller mechanism includes brush roller 10, mounting seat 11, first hand wheel 12, first screw rod 13, first adjustment block 14, second transmission motor 15 and The brush roller frame 16; the up and down horizontal acceleration belt mechanism includes a third transmission motor 17, a first pulley 19, a first conveyor belt 20, a second pulley 21, a second hand wheel 22, a second screw rod 23, and a second adjustment block 24 , Mounting frame 25, the 4th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap