Polymer displacement agent, preparation method thereof, and oil displacement method for oil reservoirs

An oil displacing agent and a polymer technology, which are applied in the field of polymer oil displacing agents and their preparation, can solve the problems of difficulty in obtaining high-viscosity polymer oil displacing agents, and achieve good long-term oil displacing effect and high appearance. The effect of viscosity retention, excellent oil displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

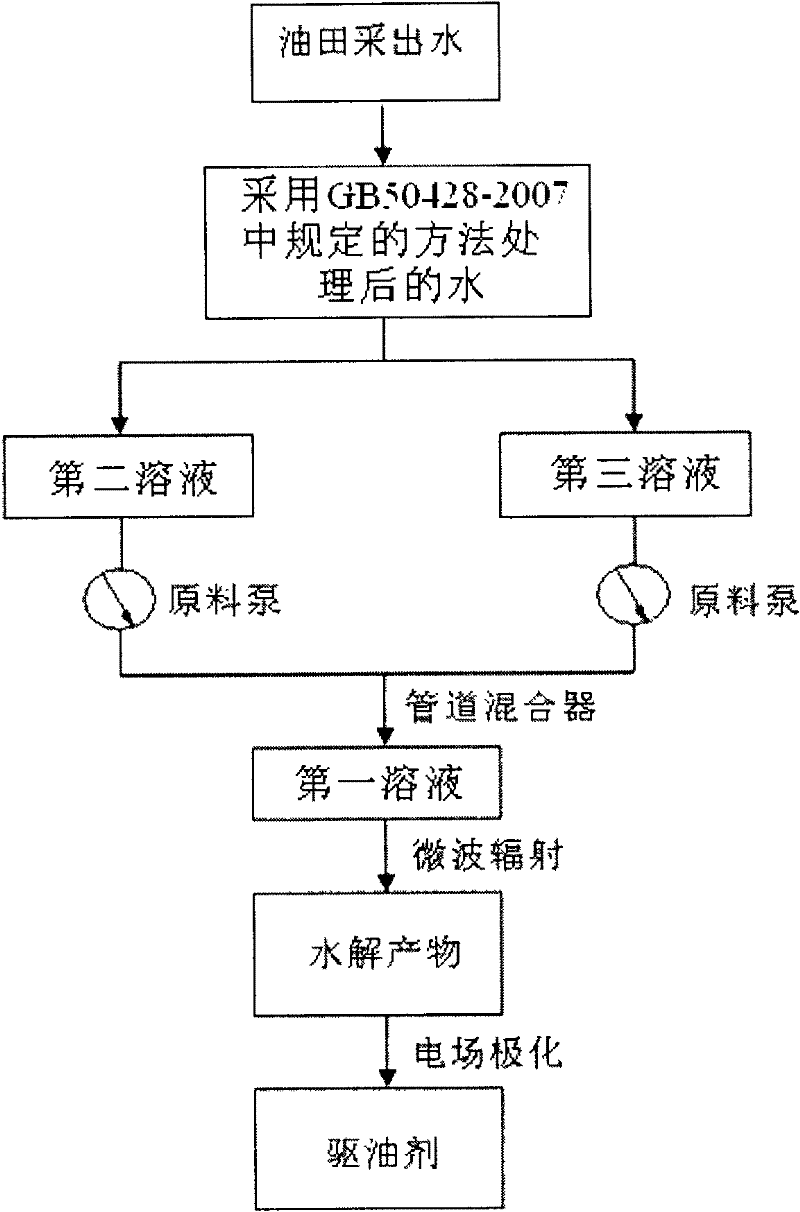

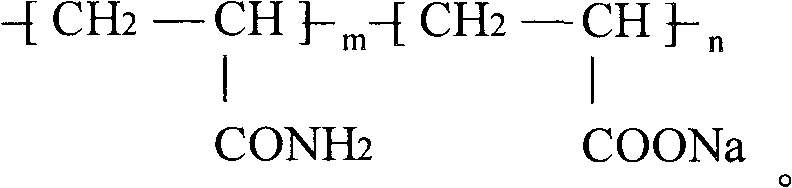

[0017] The invention provides a method for preparing a polymer oil displacement agent. The method includes providing a first solution, the first solution contains anionic polyacrylamide, wherein the solvent of the first solution has a salinity of 3000 - 20000 mg / L of water, the anionic polyacrylamide has an anionic degree of 5-35 mole %, the method further includes irradiating the first solution with microwaves to catalyze hydrolysis.

[0018] In the present invention, the degree of salinity refers to the total content of salts in water, such as: carbonates, bicarbonates, chlorides, sulfates, Nitrates; and various sodium salts. The degree of salinity in the present invention is measured according to the gravimetric method specified in the Chinese industry standard SL79-1994.

[0019] According to the present invention, the solvent of the first solution may be water with a salinity of 3000-20000 mg / L, preferably water with a salinity of 5000-15000 mg / L, more preferably a water...

Embodiment 1

[0060] This example is used to illustrate the oil displacing agent and its preparation method according to the present invention.

[0061] With the concentration of 5000 mg / L, the viscosity-average molecular weight is 16,000,000 anionic polyacrylamide (anionic degree is 15 mol%, commercially purchased from Guangzhou Xinglai Environmental Protection Equipment Co., Ltd.) dissolved in salinity is 193 mg / L water to obtain the second solution.

[0062] Sodium dodecylbenzenesulfonate is dissolved in the concentration of 2500 mg / liter in the oilfield produced water (from Shengli Oilfield) that is 7874 mg / liter through the method specified in GB50428-2007 for sterilization and impurity removal. Gudong Oil Production Plant Sewage Treatment Station), and sodium hydroxide was added to the above mixture to adjust the pH value of the solution to 11 to obtain the third solution.

[0063] according to figure 1 According to the flow process, the above-mentioned second solution and the third...

Embodiment 2

[0067] This example is used to illustrate the oil displacing agent and its preparation method according to the present invention.

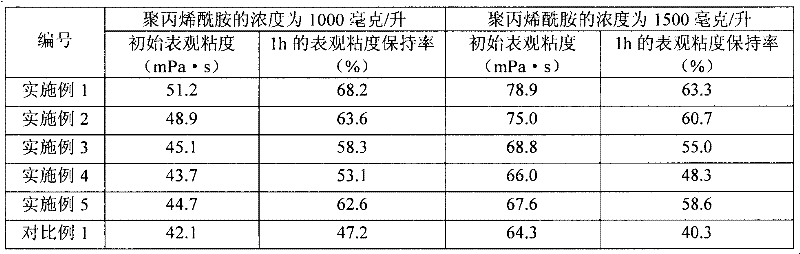

[0068] The oil displacement agent was prepared by the same method as in Example 1, except that the irradiated product was not sent into a DC electric field for polarization. Table 1 shows the initial apparent viscosity of the obtained polymer oil displacing agent (ie, the apparent viscosity measured at the end of the irradiation) and the apparent viscosity retention rate after standing for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap