Two-stage pressure revolution cushion valve

A rotary buffer and pressure valve technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of rising manufacturing costs, inconvenient installation and use, and occupying a large space, so as to achieve easy production and assembly and The effect of installation and use, reasonable structure design, and convenient maintenance and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. All equivalent technical solutions also belong to the scope of the present invention, and the patent protection scope of the present invention should be limited by the claims.

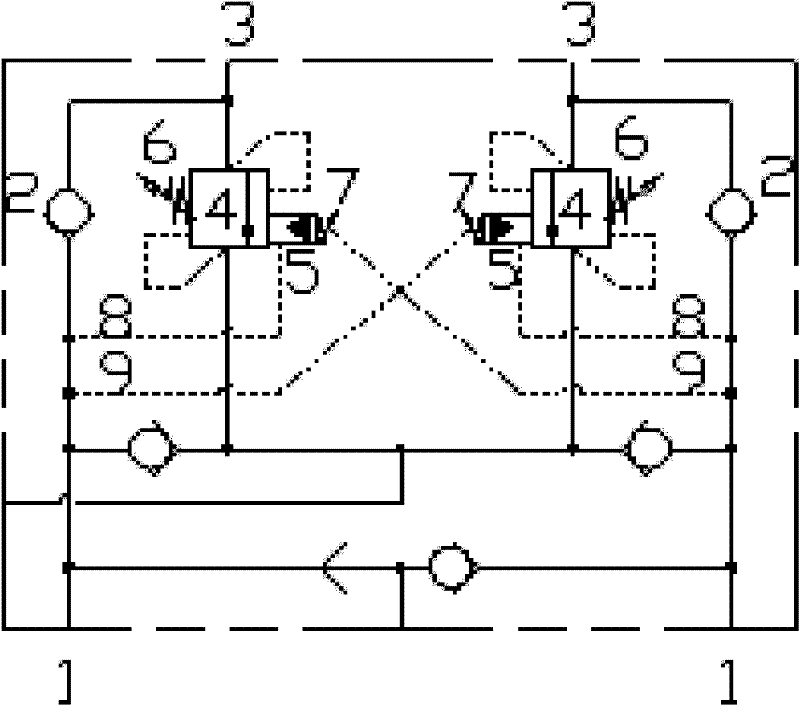

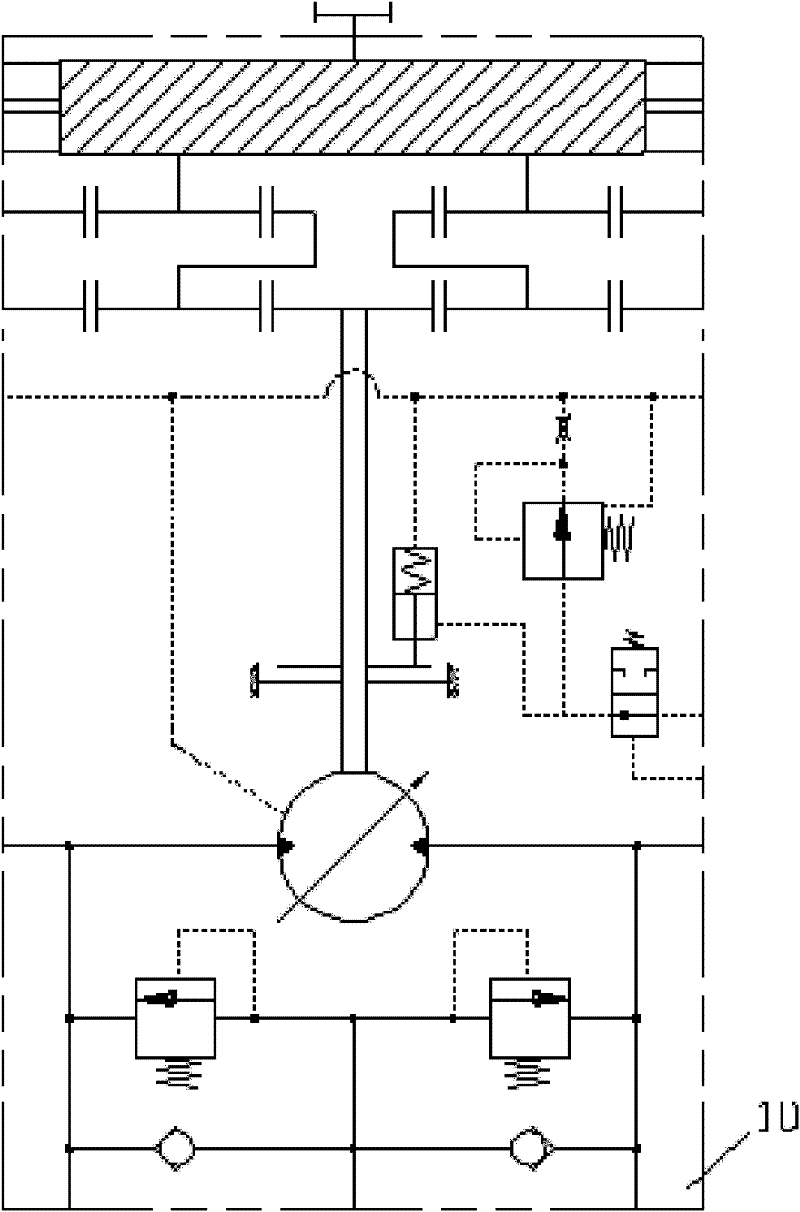

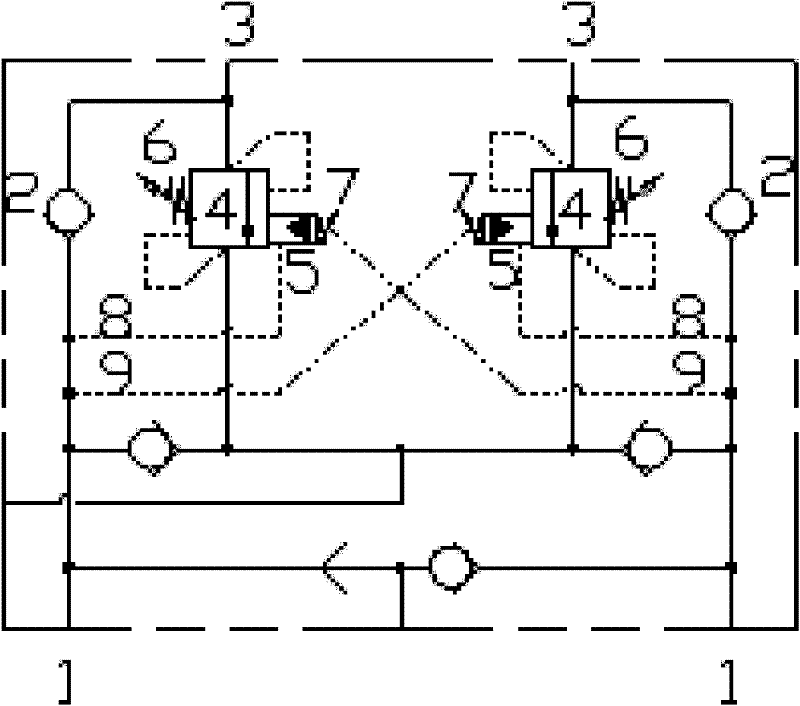

[0016] from figure 1 and figure 2 It can be seen that a two-stage pressure rotary buffer valve is composed of a pair of symmetrical two-way balance valves, an oil inlet pipe 1, a one-way valve 2 and an oil outlet pipe 3. It is characterized in that: the pair of oil inlet pipes The pipeline 1 is connected with the oil outlet pipeline 3 through a pair of one-way valves 2. The pressure spool 4 of the two-way balance valve is respectively provided with a pilot piston 5, a spring A6 and a spring B7. The pilot piston 5 passes through the oil The channel A8 and the oil channel B9 are respectively communicated with the two oil inlet pipelines 1 , and the pressure valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com