Adjustable hydraulic pilot opening mechanism

A technology of hydraulic pilot and opening mechanism, applied in the field of hydraulic components, can solve the problems of easy damage, large impact of pilot valve, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

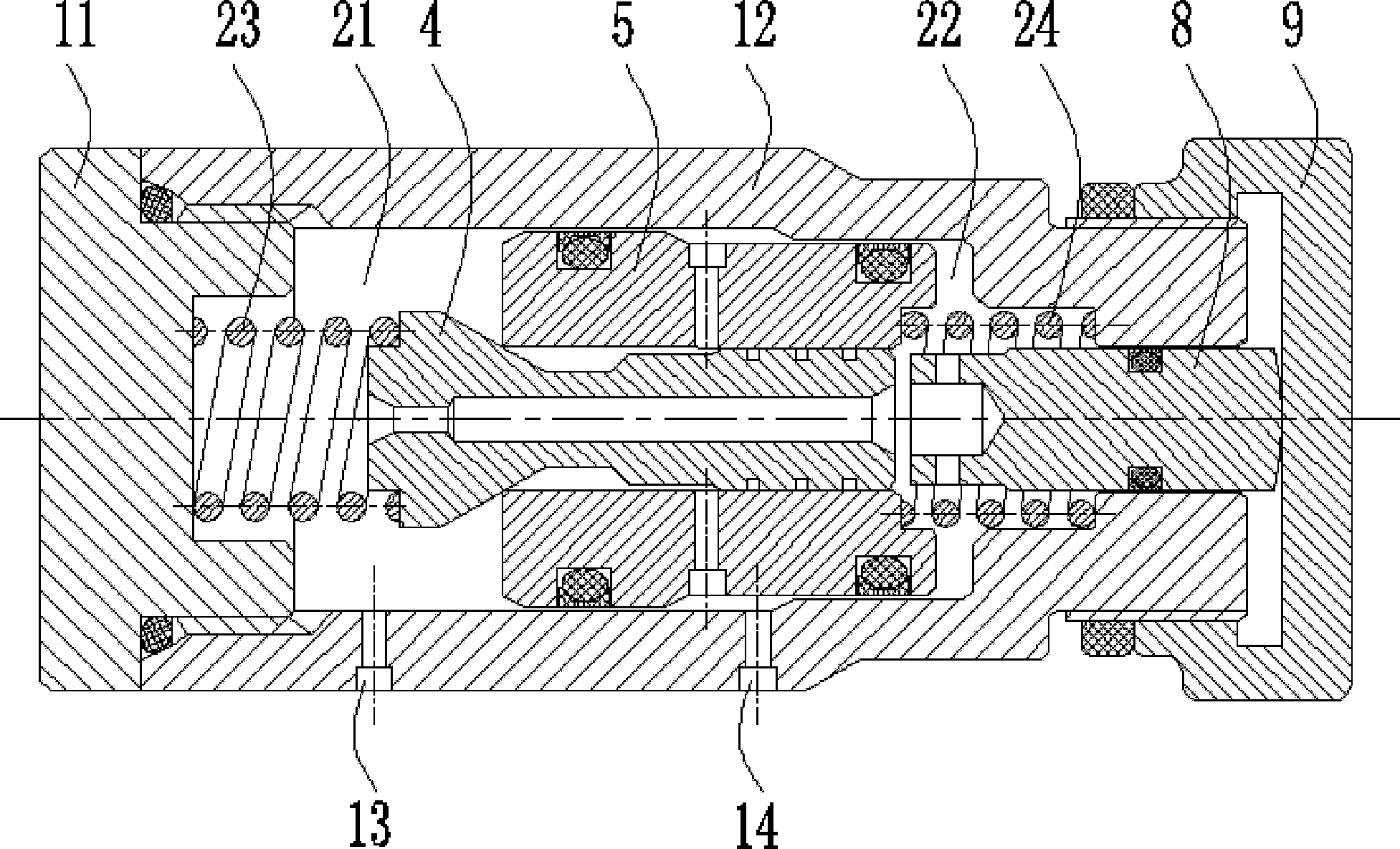

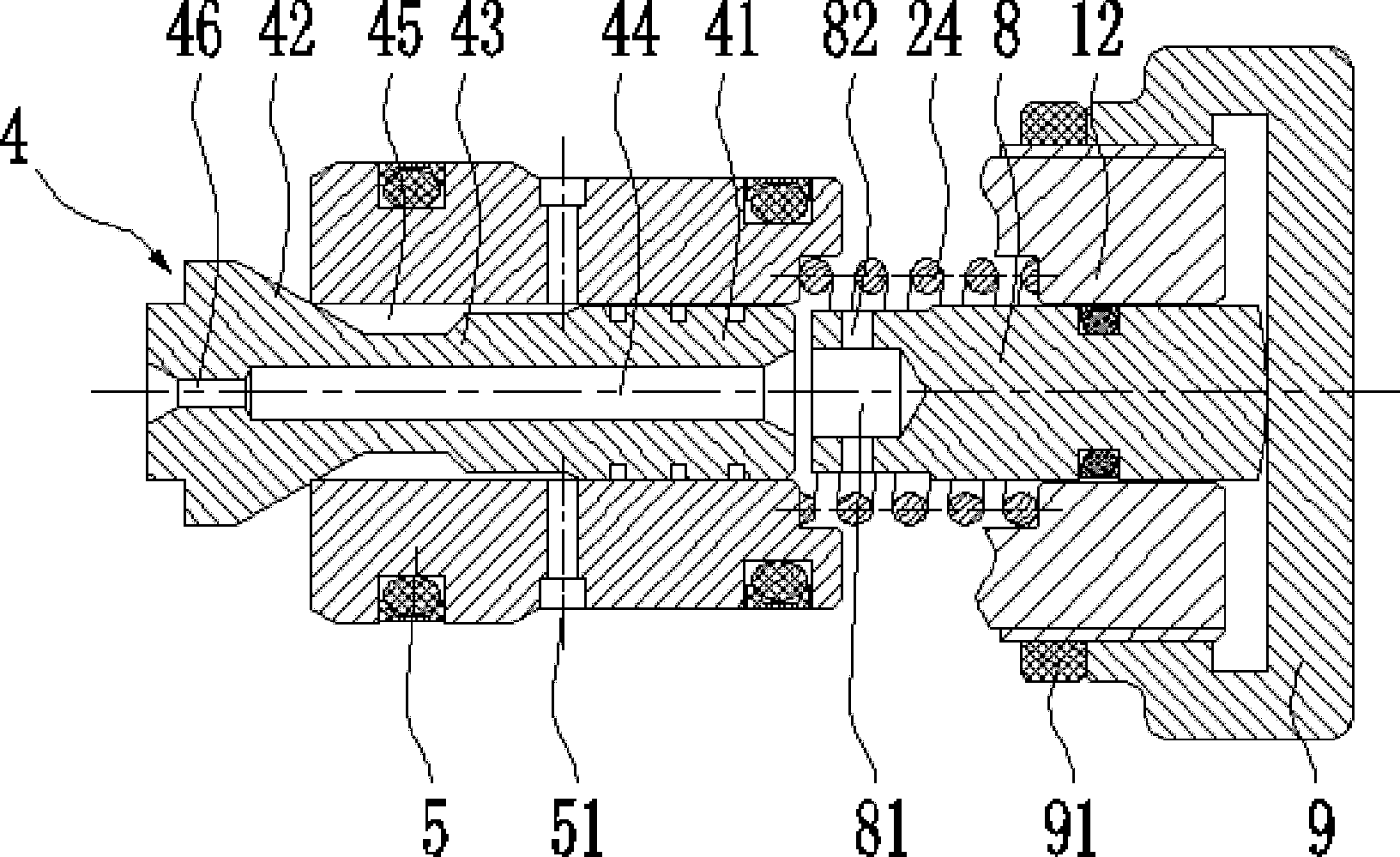

[0031] Such as figure 1 figure 2 As shown, the valve body is composed of a valve sleeve 12 and a screw plug 11 screwed on the left end of the valve sleeve 12. A valve cavity is provided in the valve body, and a pilot valve is slid in the valve cavity, wherein the left side of the pilot valve is the first One cavity 21, the right side is the second cavity 22, the pilot valve includes a pilot valve core 4 and a pilot valve seat 5, the pilot valve core 4 is provided with an inter-chamber oil connecting the first cavity 21 and the second cavity 22 Road 44, pilot valve orifice 46 is arranged on the inter-cavity oil road. The diameter of the left section of the pilot valve seat 5 is greater than the diameter of the right section, and the valve cavity also has corresponding large and small diameter sections. The effective axial force bearing area of the hydraulic oil in the second cavity 22 acting on the pilot valve is greater than the axial effective force bearing area of the...

Embodiment 2

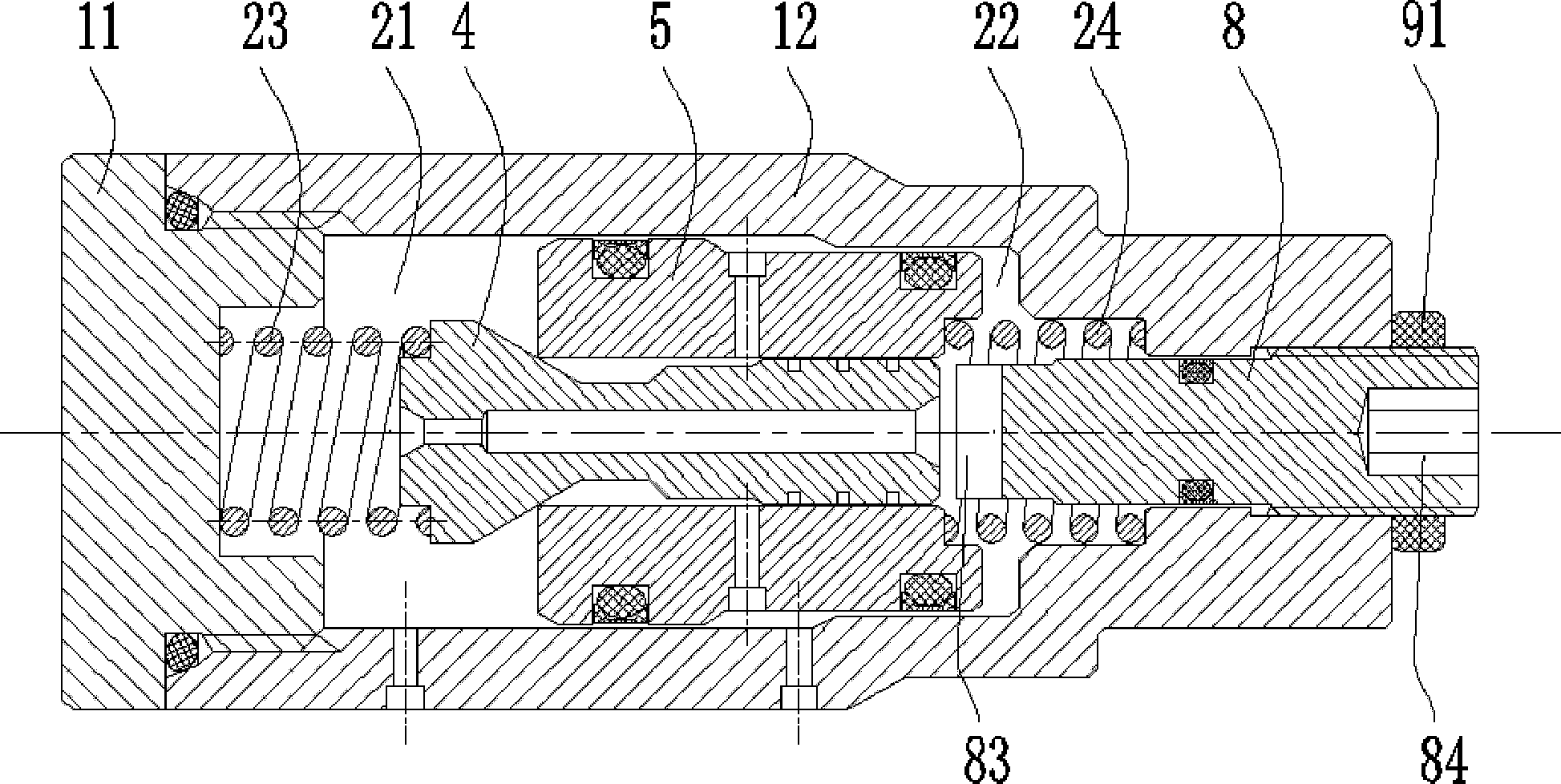

[0034] Such as image 3 As shown, compared with Embodiment 1, the difference of the pilot opening mechanism in this embodiment lies in the adjustment device. In this embodiment, the end face of the limit adjustment end of the adjustment rod 8 is provided with an end face oil groove 83, and the pilot valve core 4 When in contact with the adjusting rod 8 , the inter-chamber oil passage communicates with the second chamber through the oil groove 83 on the end surface. The other end of the adjustment rod 8 is provided with a screw thread, which forms a threaded connection with the valve sleeve 12. An inner hexagonal counterbore 84 is provided on the end face of the threaded end to rotate the adjustment rod 8 for the use of tools, and the screw end of the adjustment rod 8 is provided with And tighten the nut 9 to prevent the abnormal rotation of the adjusting rod.

Embodiment 3

[0036] Such as Figure 4 As shown, compared with Embodiment 1, the difference of the pilot opening mechanism in this embodiment lies in the valve body and the pilot valve seat. In this embodiment, the valve body is formed by screwing the valve seat 15 and the valve sleeve 12, The left section of the pilot valve seat 5 cooperates with the side wall of the inner cavity of the valve seat, and the pilot valve oil inlet 13 and the pilot valve oil outlet 14 provided on the valve seat 15 communicate with the first cavity 21 and the radial through hole 51 respectively. , the right end surface of the pilot valve seat is provided with a concave cavity, and the side wall of the cavity is slidingly fitted with the side of the adjusting rod 8 to form a second cavity 22 between the pilot valve and the adjusting rod 8, wherein the adjusting rod 8 and the pilot valve The diameter of seat 5 fitting place is less than the diameter of pilot valve seat 5 left section and valve seat 15 lumen sidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com