Cracking-prevention structure suited on lens

A technology for optical mirrors and flanges, which is applied in the field of anti-cracking structure of optical mirror sleeves. It can solve the problems of easy cracking, increased product cost, and water leakage, so as to improve air tightness, increase contact area, and prevent cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

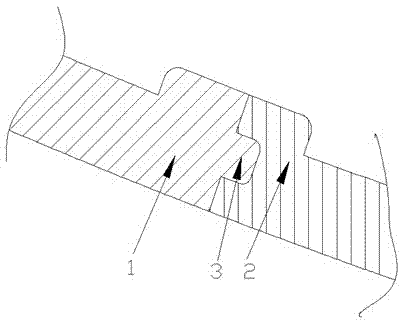

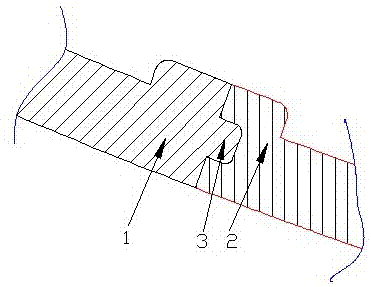

[0007] Depend on figure 1 It is well known that the light distribution mirror cover of this embodiment has a structure to prevent cracking, and the mold of the injection molding machine is molded and injected, and the light distribution mirror 1 and the injection molded light distribution mirror 2 will be integrated with each other. A flange structure 3 is added around the mirror. The size of the rib is 1 mm×1mm. The injection molded light distribution mirror 2 has a groove, and the light distribution mirror flange 3 is inserted into the groove of the injection molded light distribution mirror 2. During production and use During the process, the lamps and lanterns will be affected by forces from various aspects. The structure light distribution mirror of the present invention is red 2, and the injection molding light distribution mirror 2 is white. This structure reduces product cracking, improves product quality and qualified rate, and reduces cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com