Method for coating a wear part, use of a wear part coated according to the method, wear part and refiner

A technology for wearing parts and refiners, which is applied in coatings, metal material coating processes, pulp beating/refining methods, etc., and can solve problems such as accelerated wear of wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

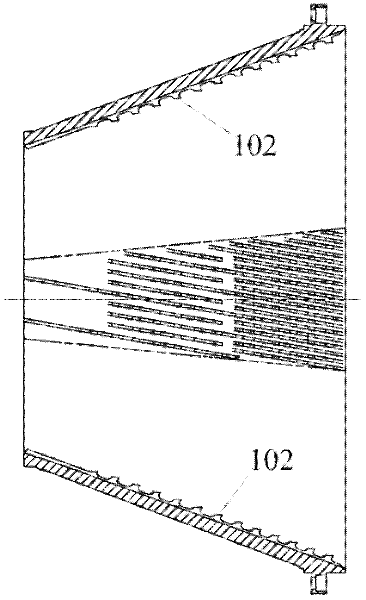

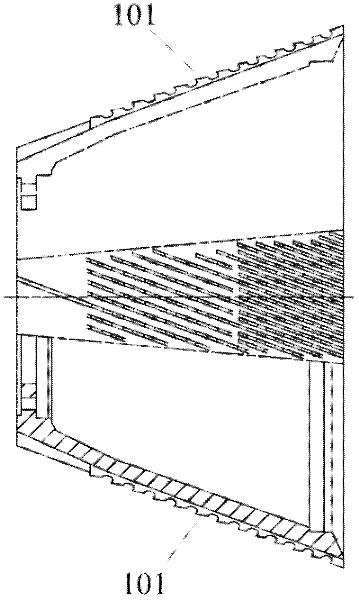

[0060] Figure 1A and Figure 1B The stator and rotor of a disperser are shown respectively, together with an example of conical refiner blade elements used in the disperser. The stator and rotor are shown in section. The first refiner surface, blade surface 101 is located in the rotating rotor of the refiner, disperser or defibrator and the second refiner surface is located in the stationary stator of the refiner, disperser or defibrator middle. The refiner surfaces can be formed directly as part of the stator / rotor or they can be made as separate blade segments or blade sections in a manner known in the art. The refiner surface comprises blade bars and grooves between the blade bars.

[0061] The refiner blade element may be in the shape of a plate, cylinder, cone, partially planar surface, partially cylindrical surface, partially conical surface or any combination of these.

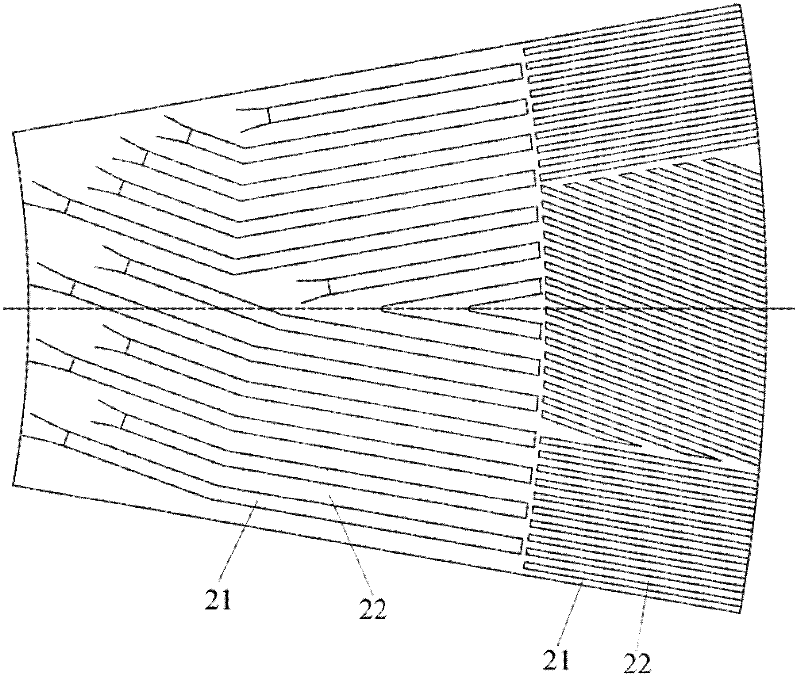

[0062] figure 2 A plan view showing an example of a plate refiner blade element. A plurality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com