Multi-stage turbocharger arrangement

A technology of turbochargers and superchargers, which is applied to gas turbine devices, machines/engines, combustion engines, etc., and can solve problems such as exhaust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

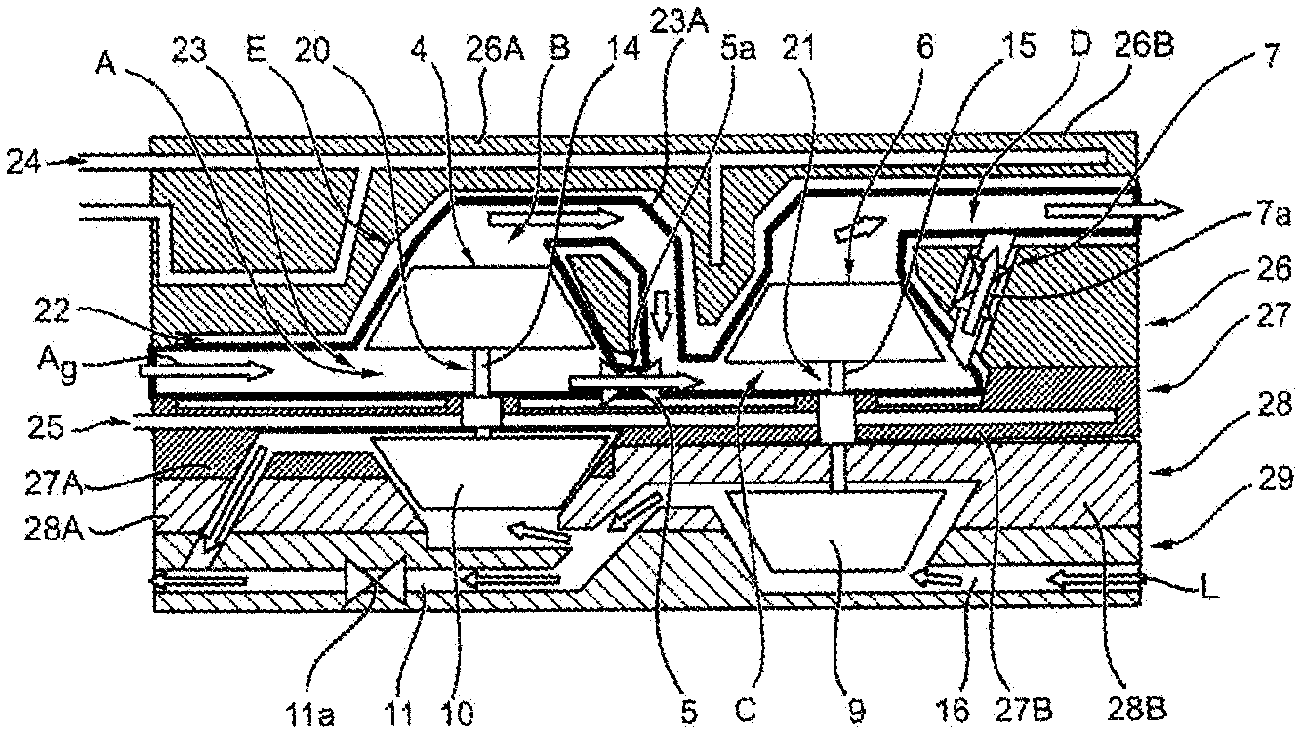

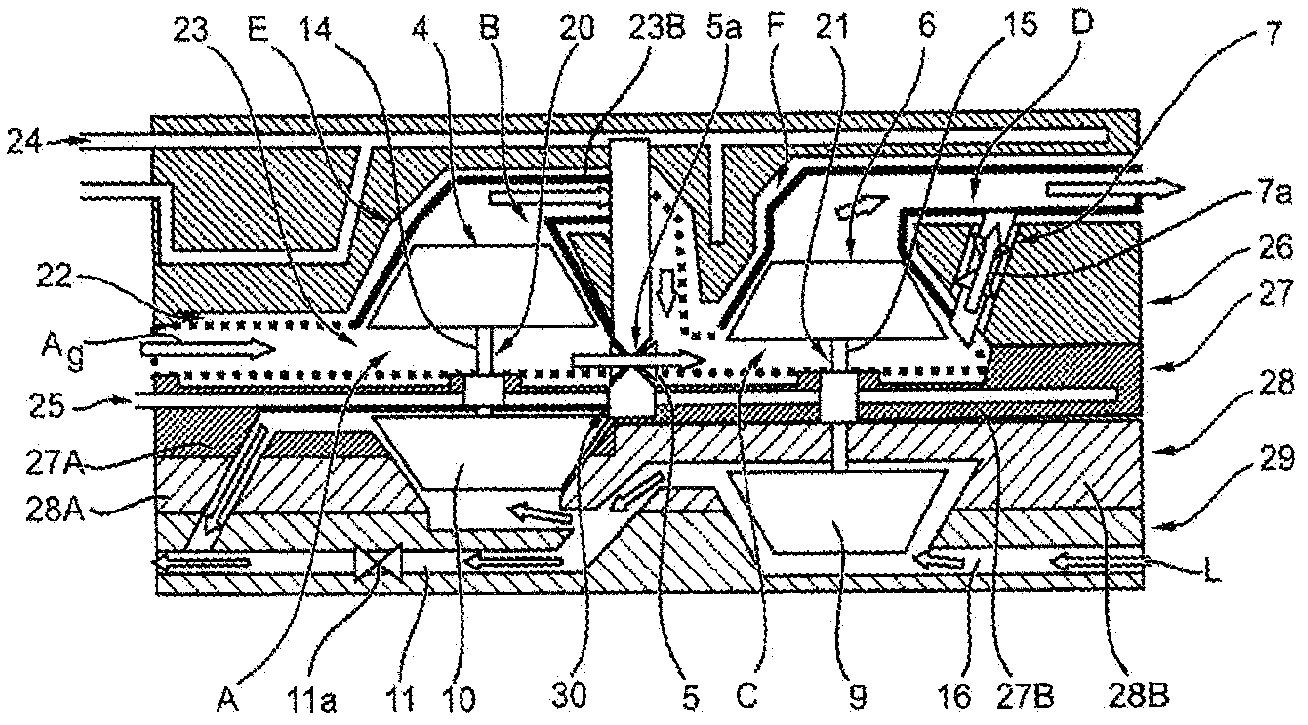

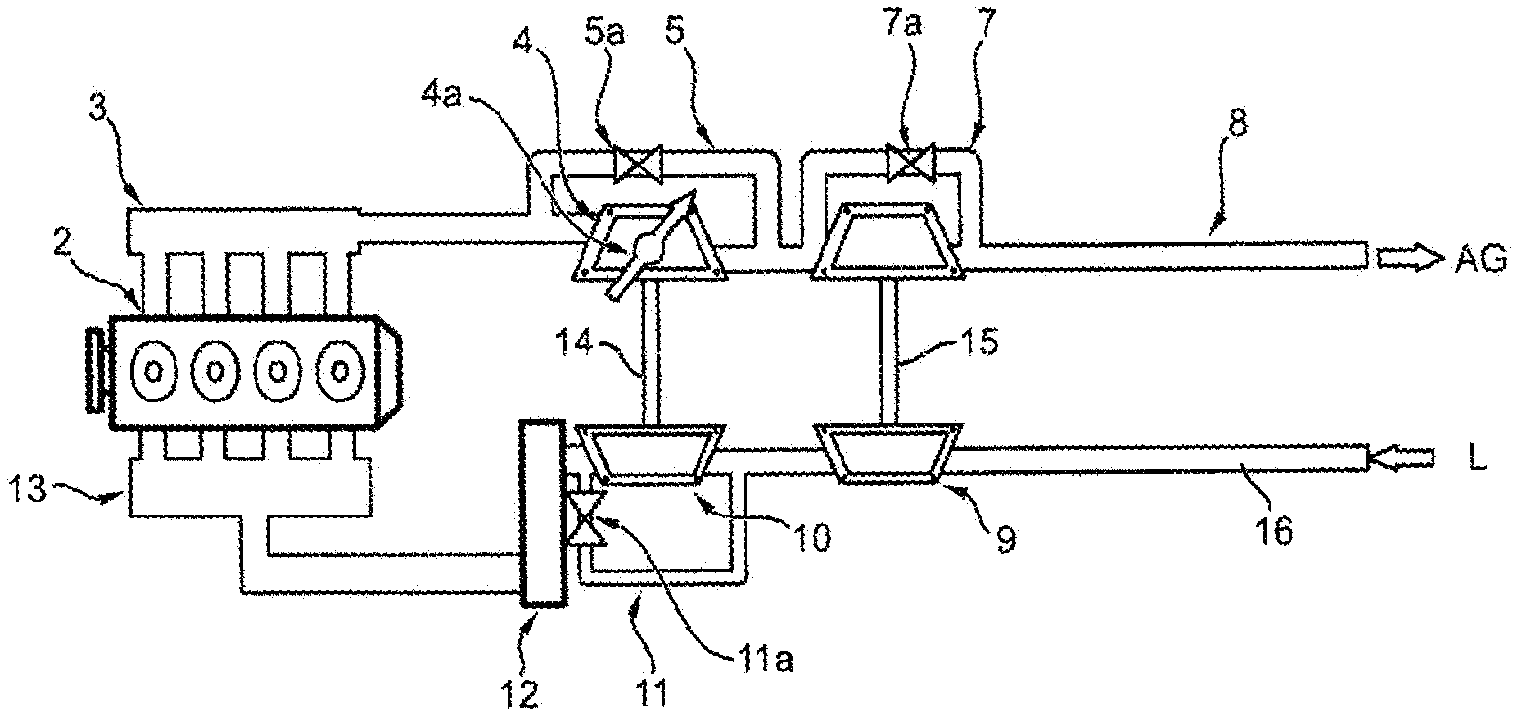

[0011] see figure 1 , a first embodiment of the multi-stage turbocharger arrangement 1 according to the invention will be described below. as from figure 1 As can be seen in the figure, the multistage turbocharger arrangement 1 has a high-pressure turbocharger 20 and a low-pressure turbocharger 21, the high-pressure turbocharger has a high-pressure turbine 4, which is connected via a shaft 14 to a on the high-pressure compressor 10; and the low-pressure turbocharger has a low-pressure turbine 6 connected via a shaft 15 to a low-pressure compressor 9. The high-pressure turbine 4 and the low-pressure turbine 6 are arranged in a common turbine housing unit 26, which is divided into a turbine housing section 26A of the high-pressure turbocharger 20 and the low-pressure turbine A turbine housing section 26B of the supercharger 21 . An inner casing 23 , which can expand due to heat, is inserted inside the turbine housing unit 26 , inside which hot engine exhaust gas Ag flows thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com