Heavy-load self-limited locking pneumatic-overturning device

A flipping device and heavy-duty technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high cost, inconvenient installation and maintenance, heavy weight, etc., and achieve small occupation, compact structure, flat surface small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

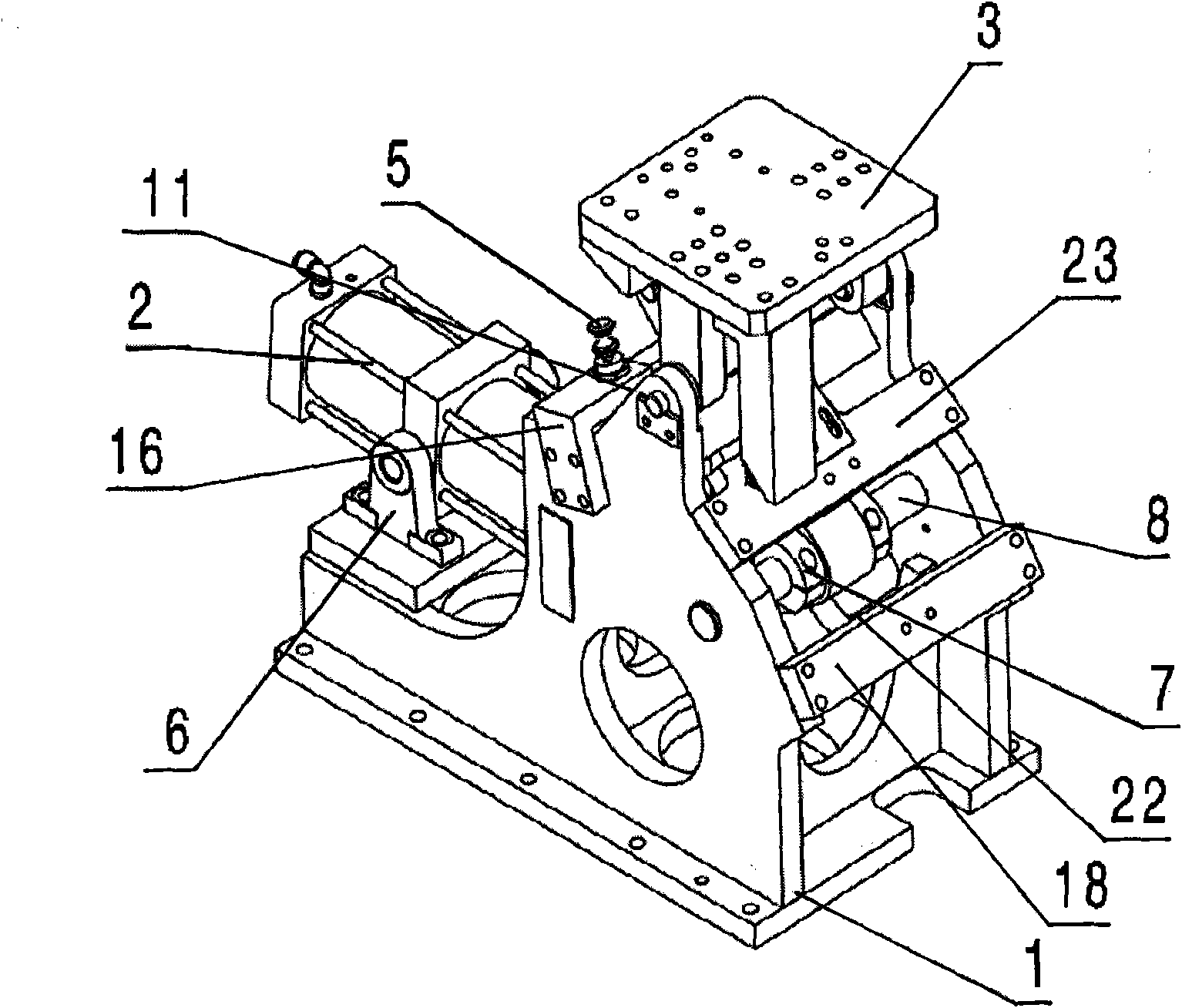

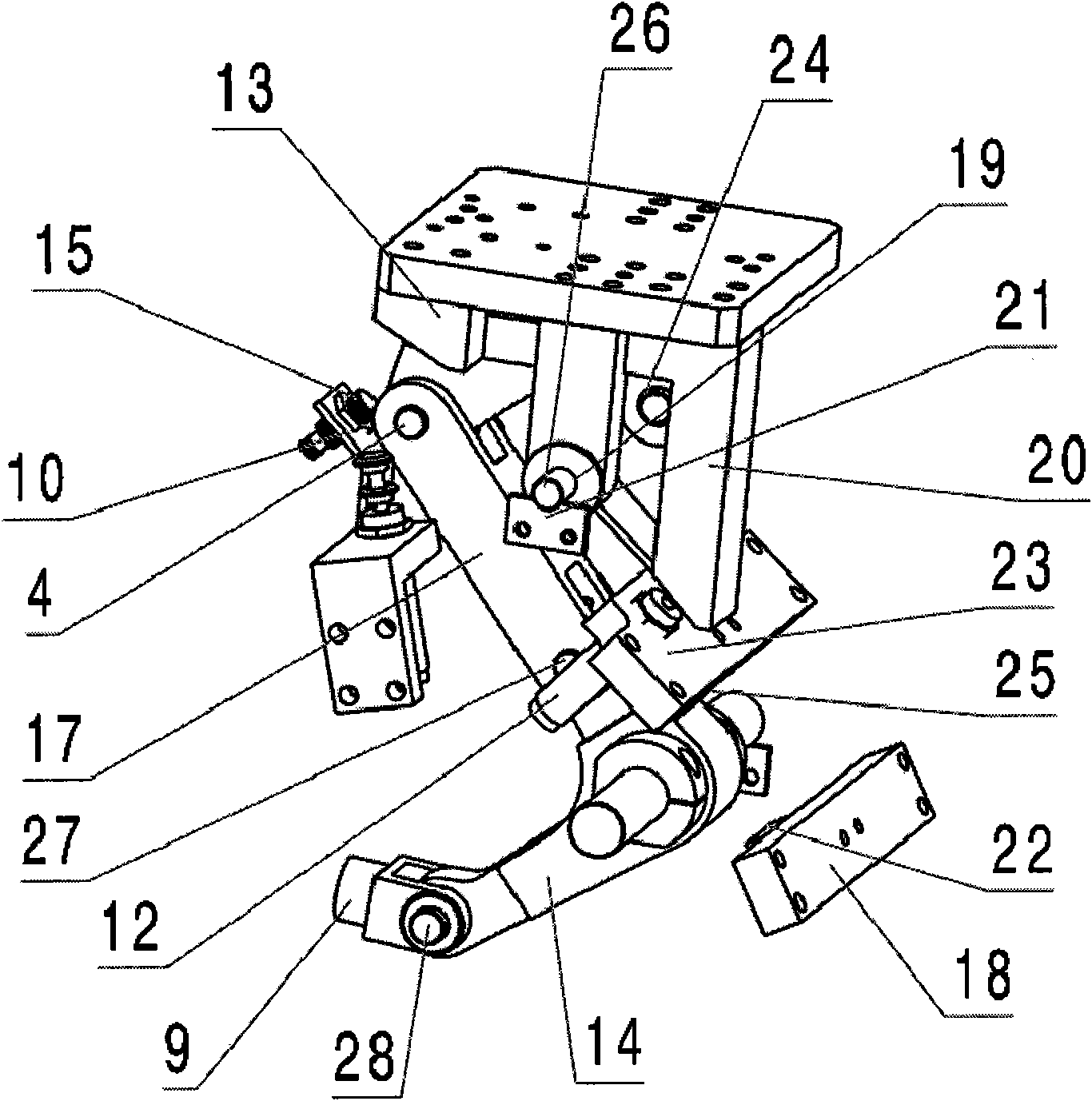

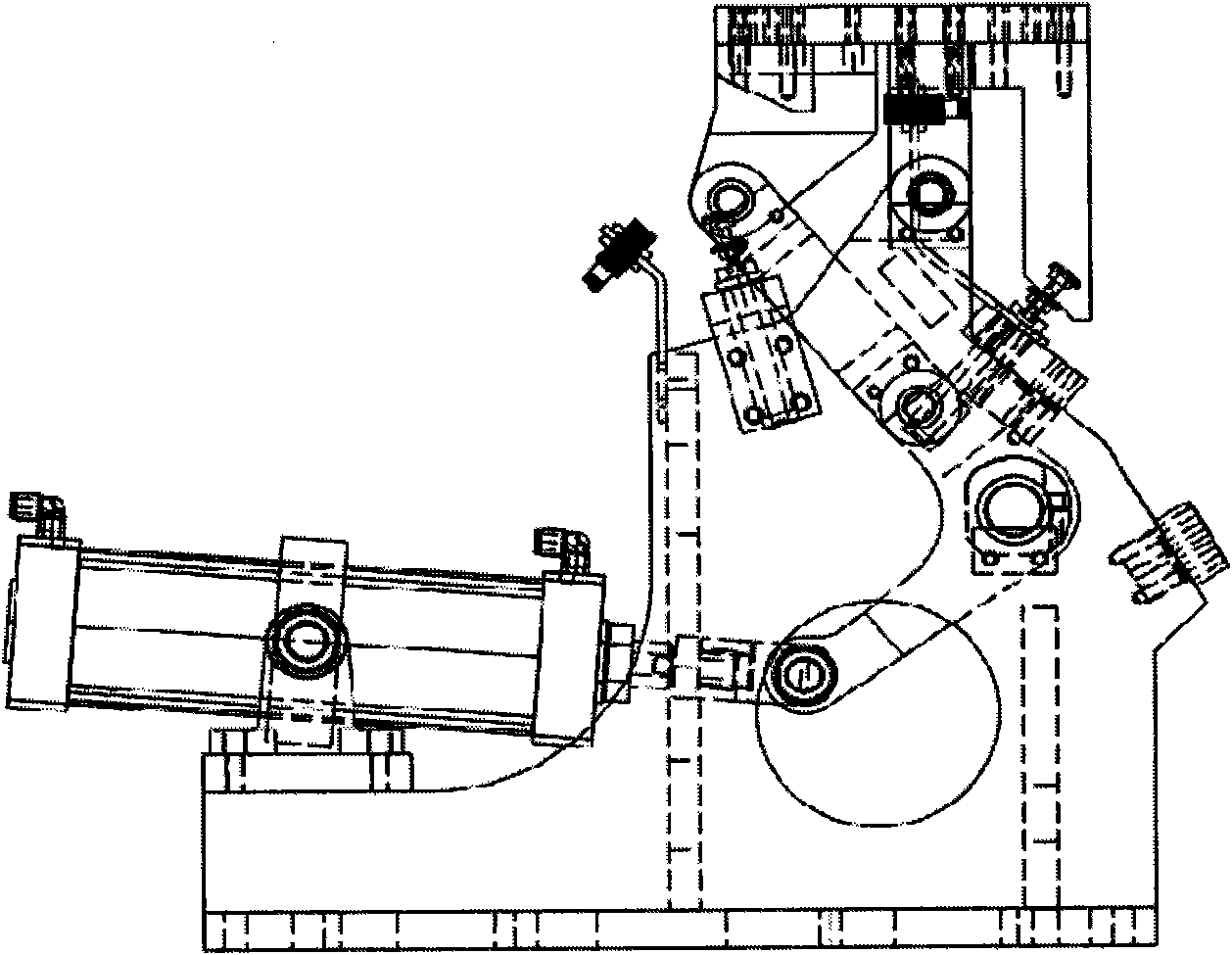

[0008] The cylinder 2 is fixedly connected with the large welding support 1 through the cylinder support 6, the limit block one 22 is fixedly connected with the large welding support 1 through the limit seat 18, the connection block one 16, the buffer one 5, the connection block two 23, Buffer two 12 are respectively fixed on the large welded support 1, the fixed hinge one 8 and the oil-free bushing 7 are fixed on the large welded support 1, the cylinder 2 is connected with the crank 14 through the cylinder joint 9 through the movable hinge two 28, and the fixed hinge One 8 is connected with the crank 14, the crank 14 and the connecting plate 17 are hinged through the living hinge one 27, the connecting plate 17 is connected with the loading seat 3 and the living hinge three 4, and the loading seat 3 is respectively passed through the small hinge shaft one 11 and the small hinge shaft two 24 , the baffle plate 21 is fixed on the large welded support 1 to form a fixed hinge 2 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com