Processing method and tool for tapered pin hole of clamp arm of 450-ton manipulator

A processing method and taper pin technology, which are applied to the processing of taper pin holes of clamp arms of 450-ton manipulators and the fields of taper inspection tools, can solve the problems of inability to meet the requirements of use and difficulty in manufacturing clamps, and simplify manufacturing and testing. process, solve manufacturing difficulties, and improve the effect of manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

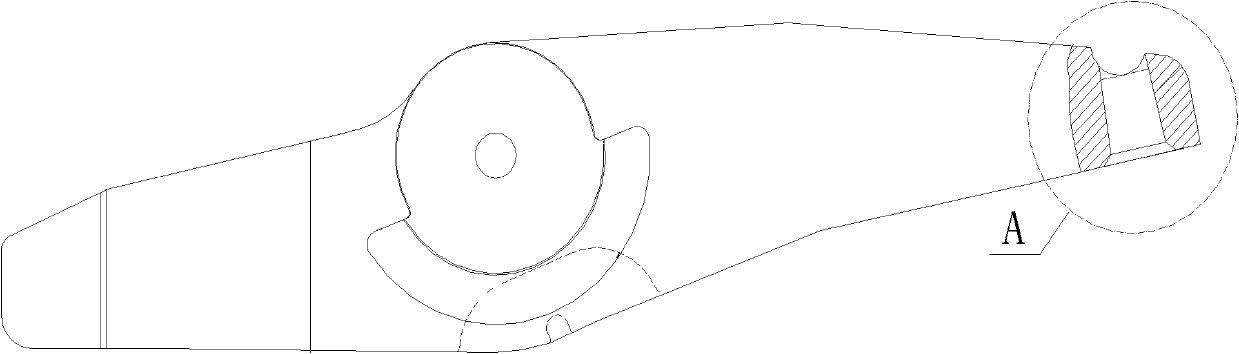

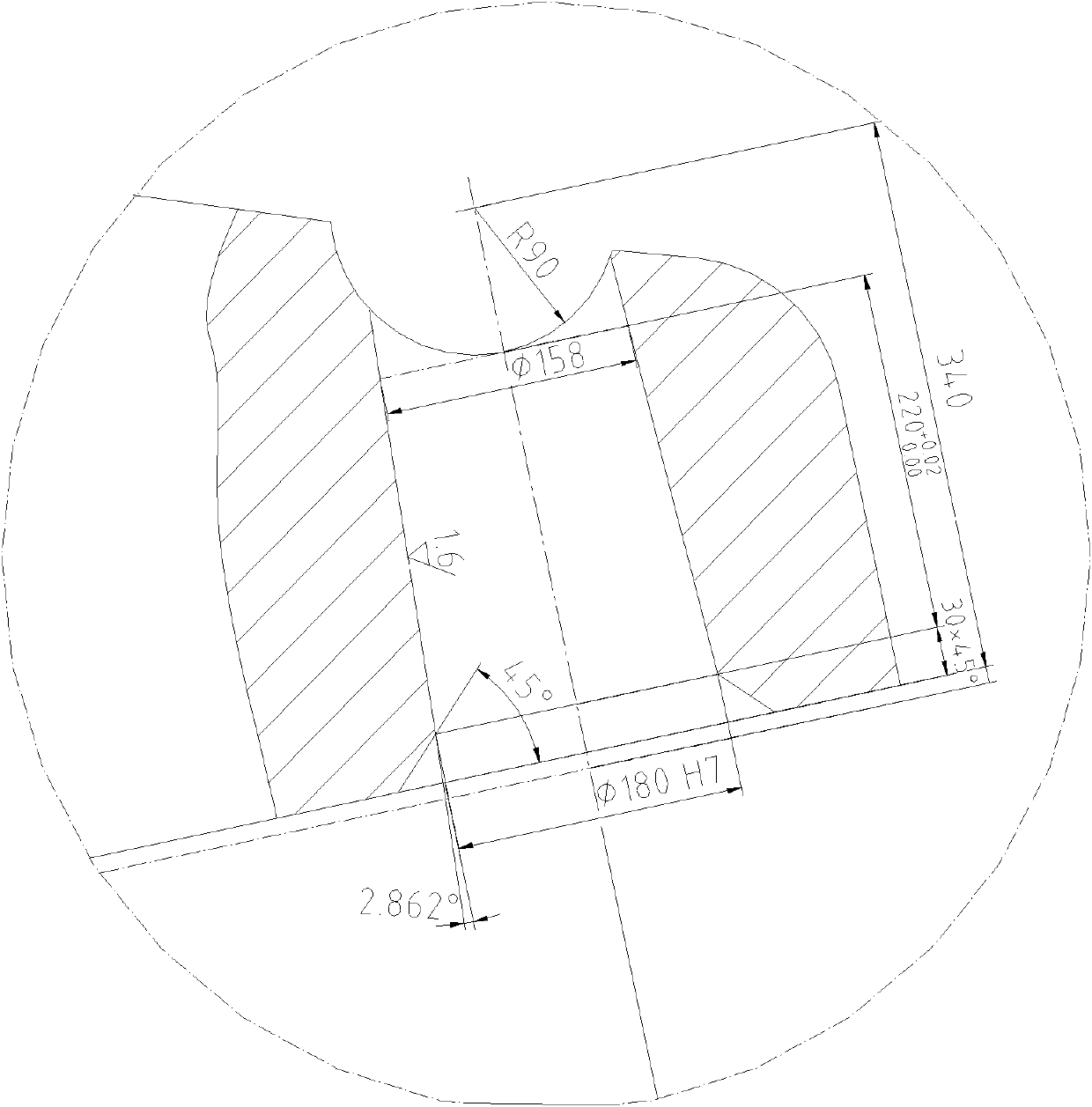

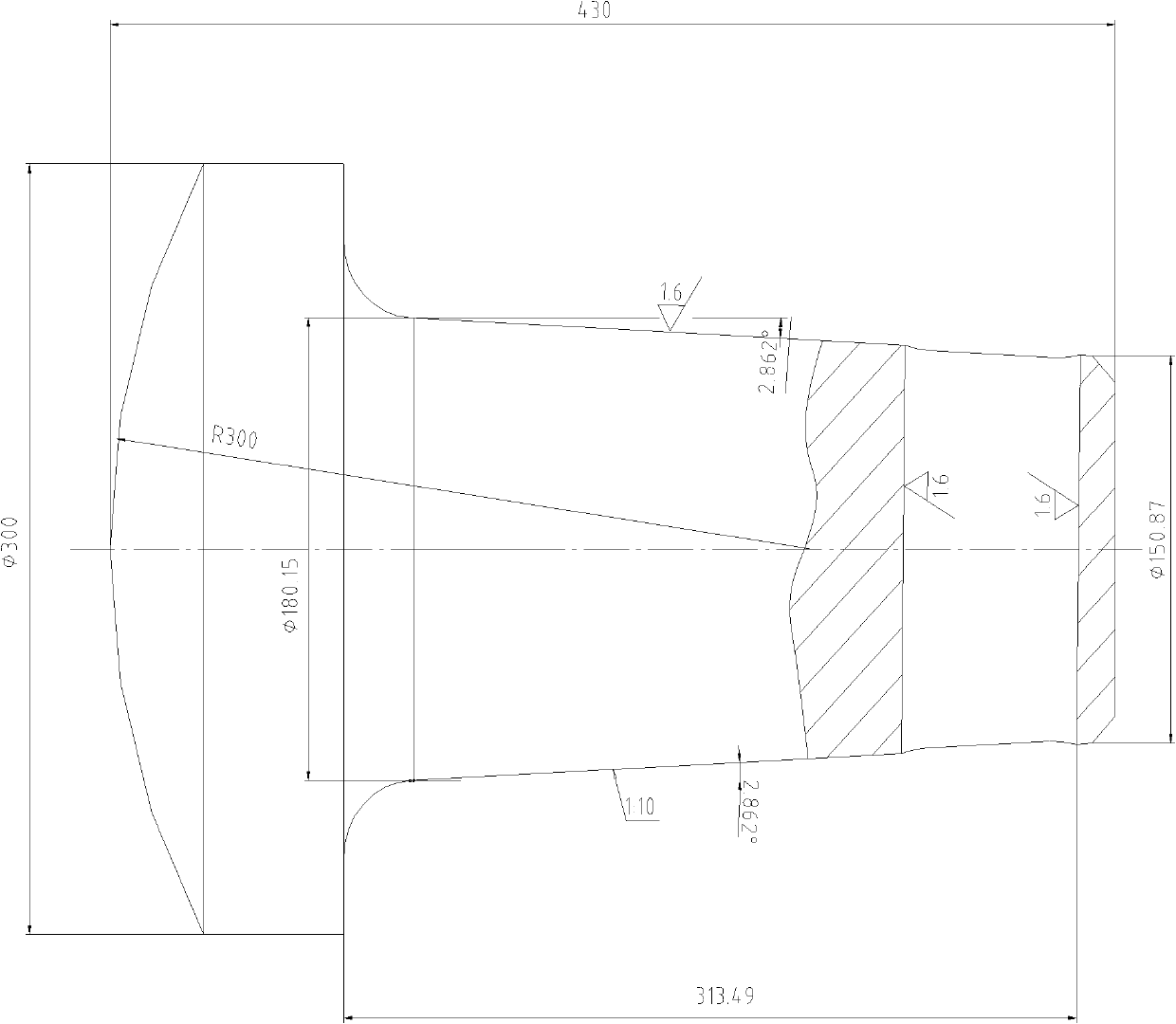

[0030] The processing method of the taper pin hole of the clamp arm of the 450 ton manipulator of the present invention is used for processing such as figure 1 , figure 2 The tapered pin hole of the clamp arm of the 450-ton manipulator shown, the inner diameter of the large end of the tapered pin hole is φ180 (+0.04 / 0)mm, and the angle is 2.862°. The corresponding pin shaft of the tapered pin hole is as follows image 3 As shown, the outer diameter of the big end is φ180 (-0.014 / -0.054) mm, the height is 430 mm, and the weight of the pin shaft is more than 100 kg.

[0031] The present invention utilizes the taper inspection tool to realize the matching of the pin shaft and the taper pin hole to meet the matching requirements of the assembly taper, including the following steps:

[0032] The first step is to make a taper inspection tool;

[0033] Taper inspection tools such as Figure 4 As shown, the taper body 1 is included, and the taper body 1 is hollow. The taper surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com