Berth launching transverse shifting movable track

A track and slipway technology, applied in the slipway field in shipbuilding, can solve the problems of labor-intensive, expensive, affecting safety production, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

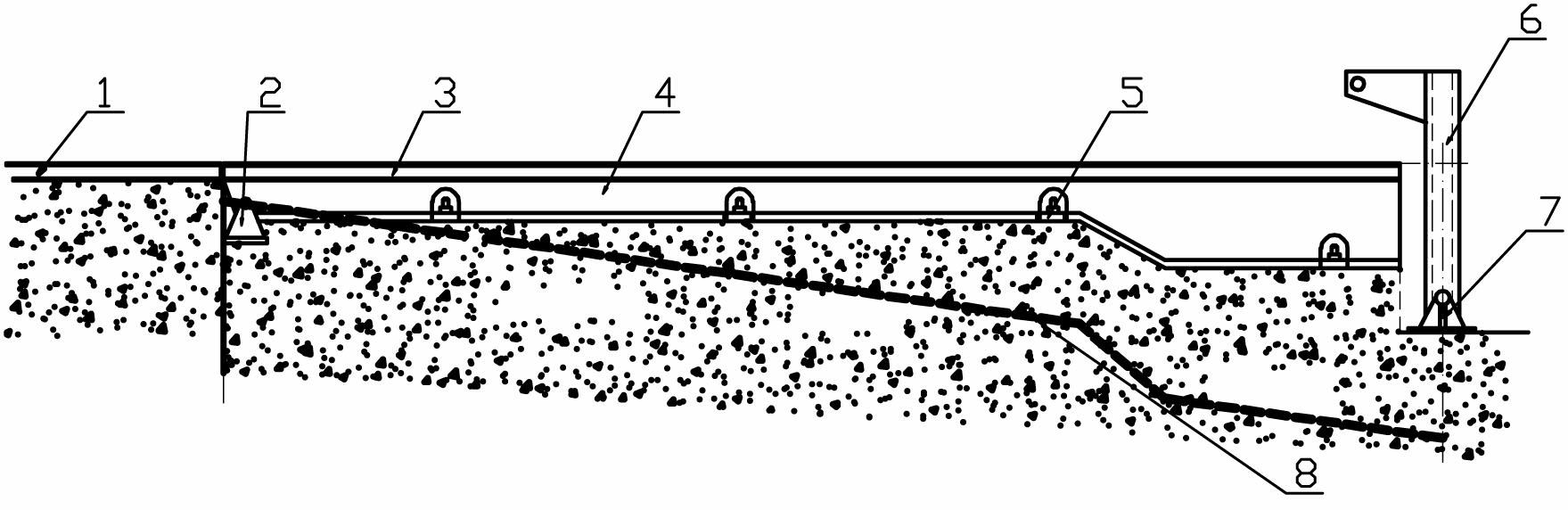

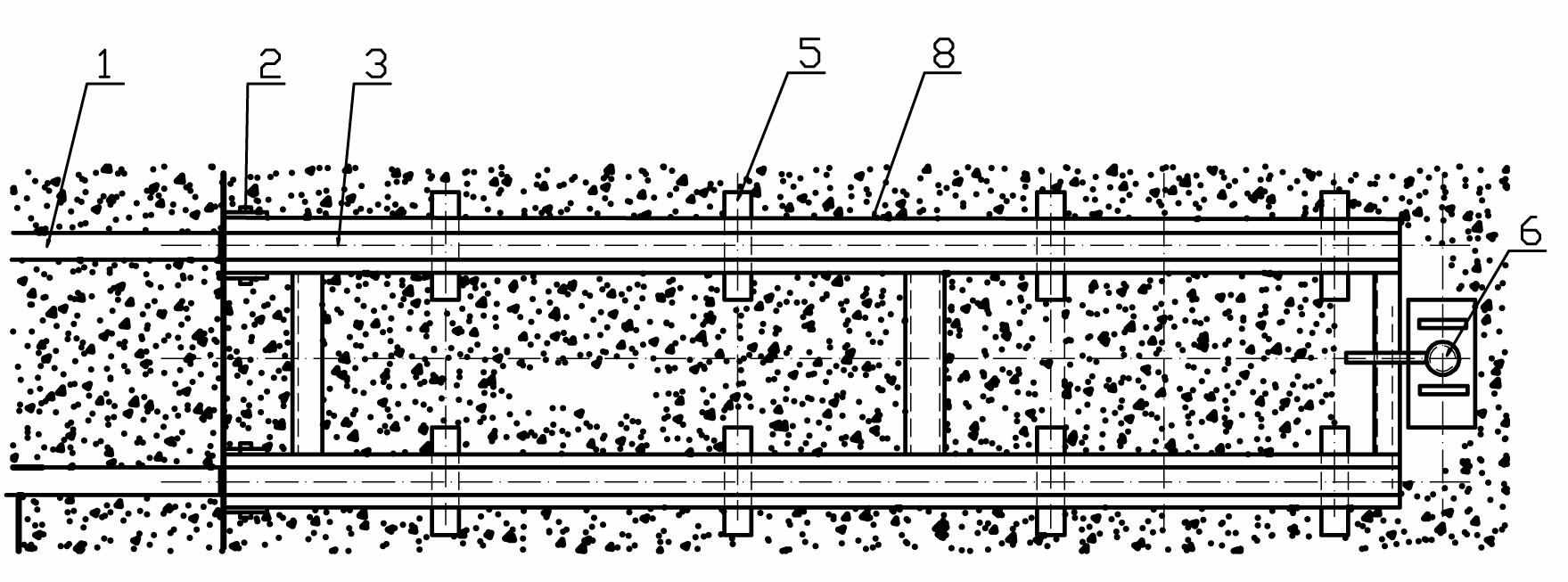

[0017] Such as figure 1 , figure 2 Among them, a movable track for launching lateral movement of a slipway, the frame girder 4 is installed on one end of the slipway rail 1 through a hinge 2, the movable rail 3 is arranged on the frame girder 4, the movable rail 3 near the end of the hinge 2 is connected with the slipway rail 1, etc. The bottom of the frame girder 4 is provided with a plurality of support plates 5, and the frame girder 4 is provided with a concrete groove 8 for accommodating the frame girder 4. The frame type girder 4 has a length of 6 meters and a width of 260 mm, and the width of the concrete groove 8 is 280 mm.

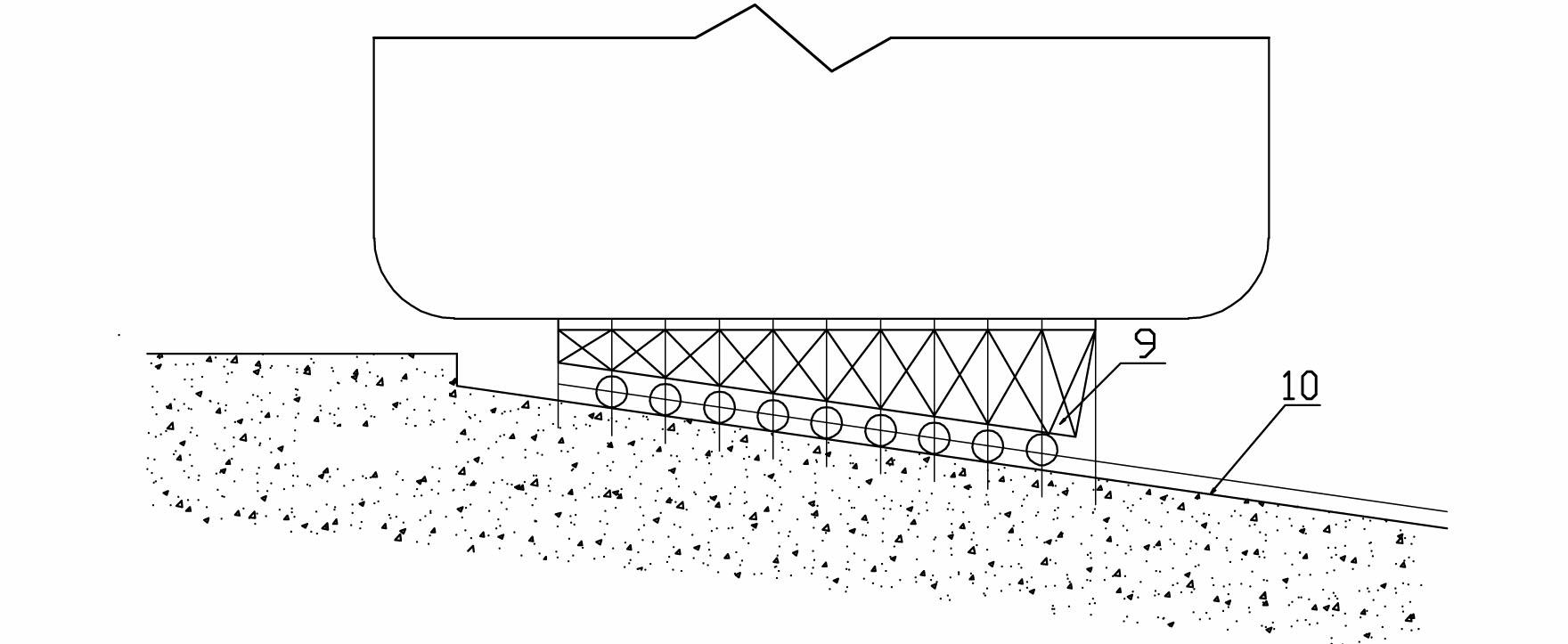

[0018] The concrete groove 8 has the same slope as the comb slideway 10 . For example: the same slope of 1:7.

[0019] The support plate 5 is connected with the frame type girder 4 through a pin shaft, and can rotate around the pin shaft.

[0020] There are 8 support plates 5, which are arranged equidistantly on both sides of the frame-type g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com