Waste drilling fluid gel breaker system

A technology of waste drilling fluid and gel breaker, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve remarkable experimental results and small environmental changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

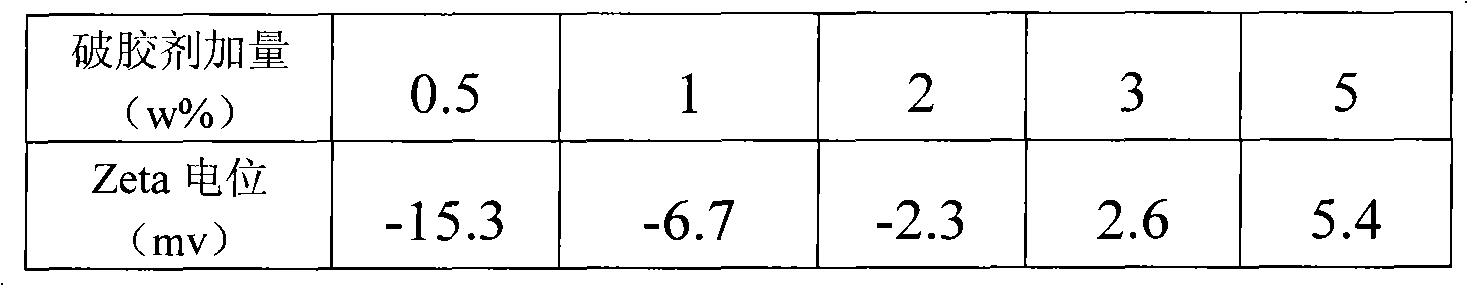

[0014] Under normal temperature and pressure, compound calcium chloride, aluminum sulfate, ammonium stearate and ammonium dibutylnaphthalene sulfonate in proportions of 15%, 5%, 60%, and 20% by weight to form a composite breaker. Take 5kg of waste drilling fluid, add 0.5%, 1%, 2%, 3%, and 5% of compound gel breaker, and measure its zeta potential and gel breaking condition.

[0015] Table 1 Changes in zeta potential of waste drilling fluid after adding different amounts of breakers

[0016]

Embodiment 2

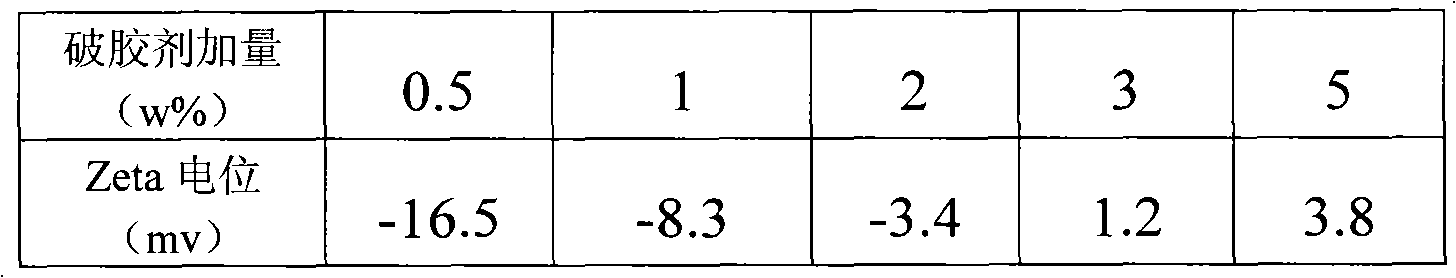

[0018] Under normal temperature and pressure, compound calcium chloride, aluminum sulfate, ammonium stearate and ammonium dibutyl naphthalene sulfonate in proportions of 10%, 5%, 65%, and 20% by weight to form a composite breaker. Take 5kg of waste drilling fluid, add 0.5%, 1%, 2%, 3%, and 5% of compound gel breaker, and measure its zeta potential and gel breaking condition.

[0019] Table 2 Changes in zeta potential of waste drilling fluid after adding different amounts of breakers

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com