Method for preparing magnoflorine from Chinese medicinal Chelidonium majus L.

A technology of magnolia and celandine, applied in the direction of organic chemistry and the like, can solve the problems of high consumption of organic solvents, cumbersome silica gel column chromatography process, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

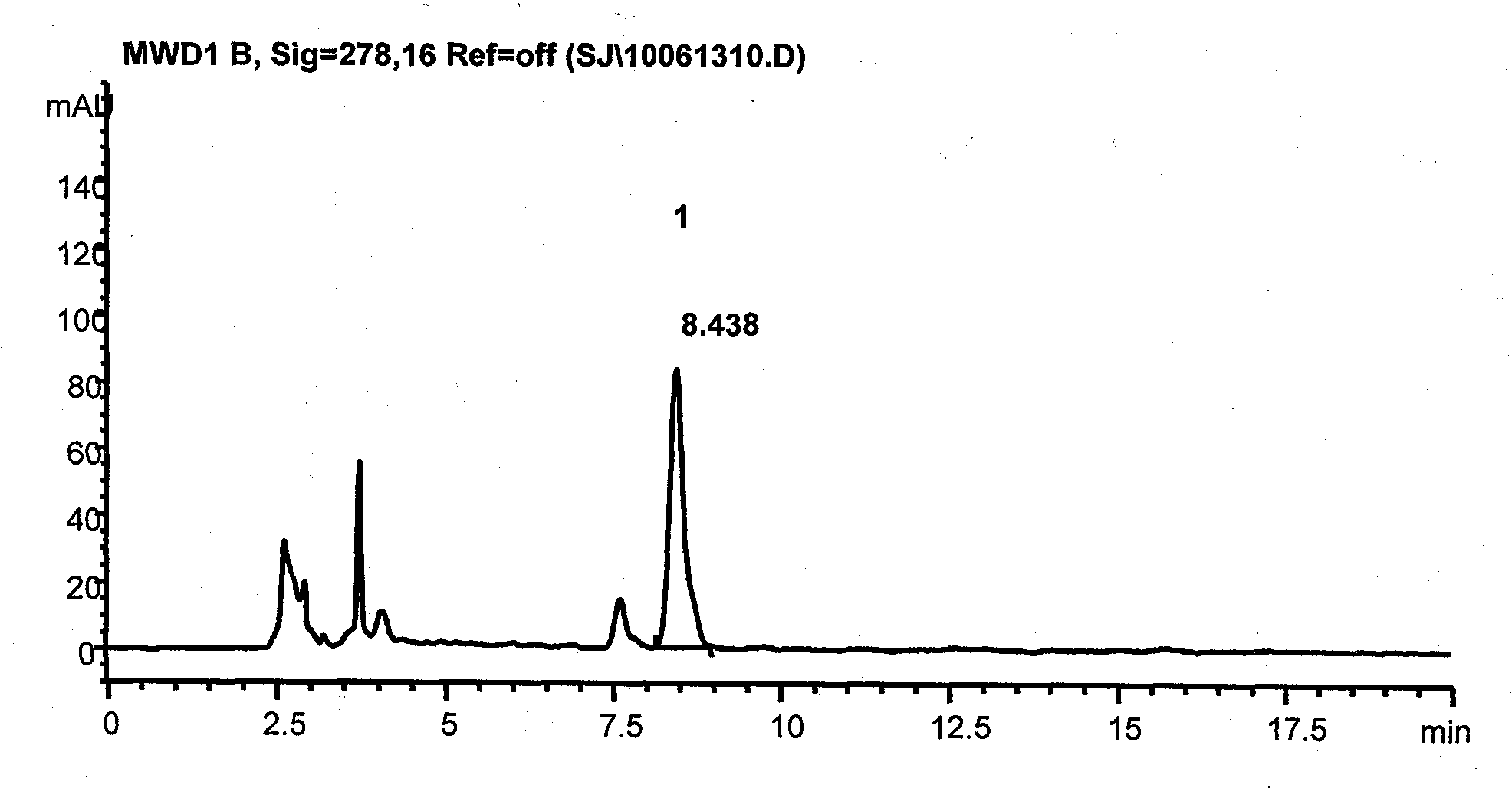

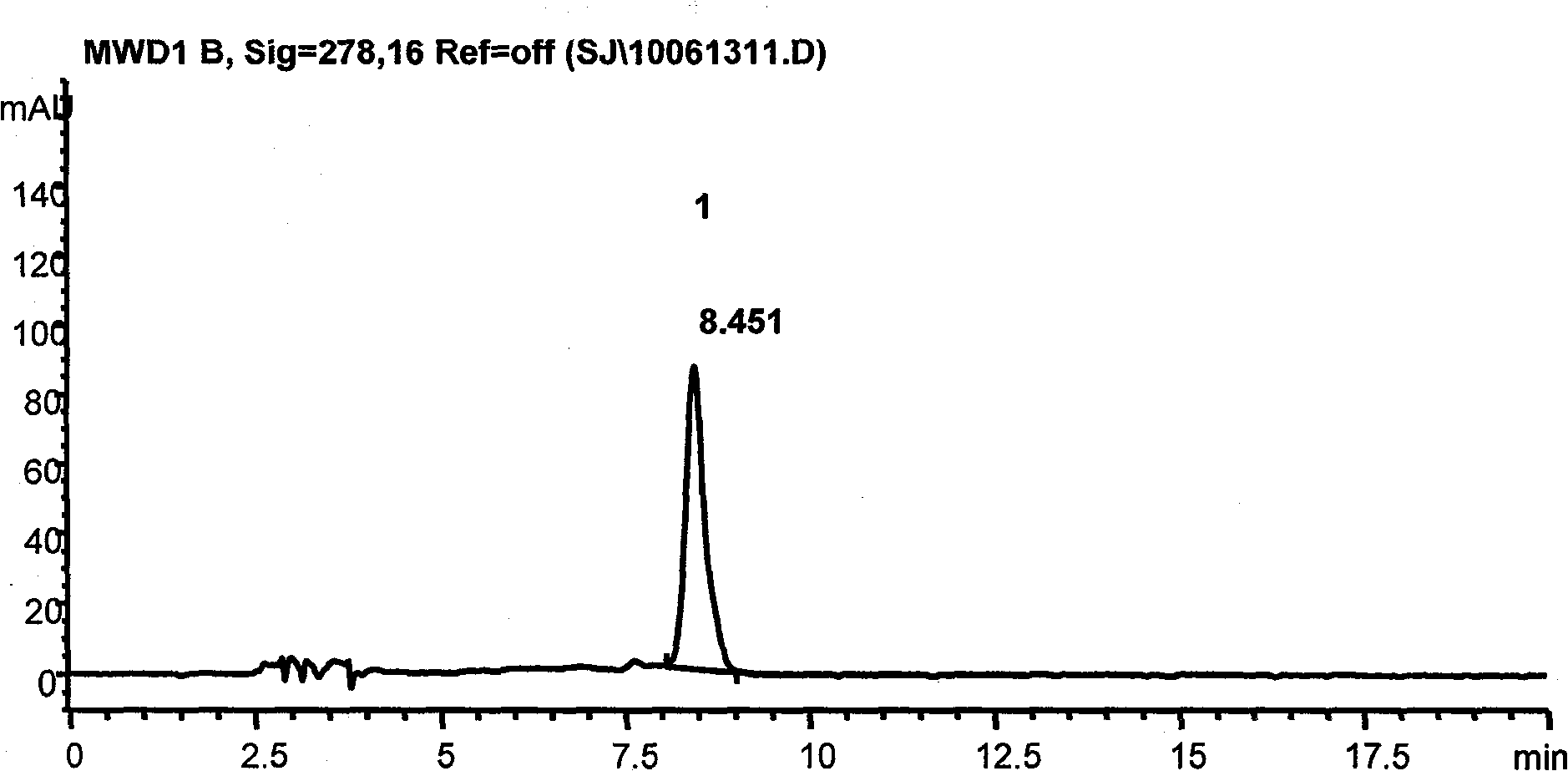

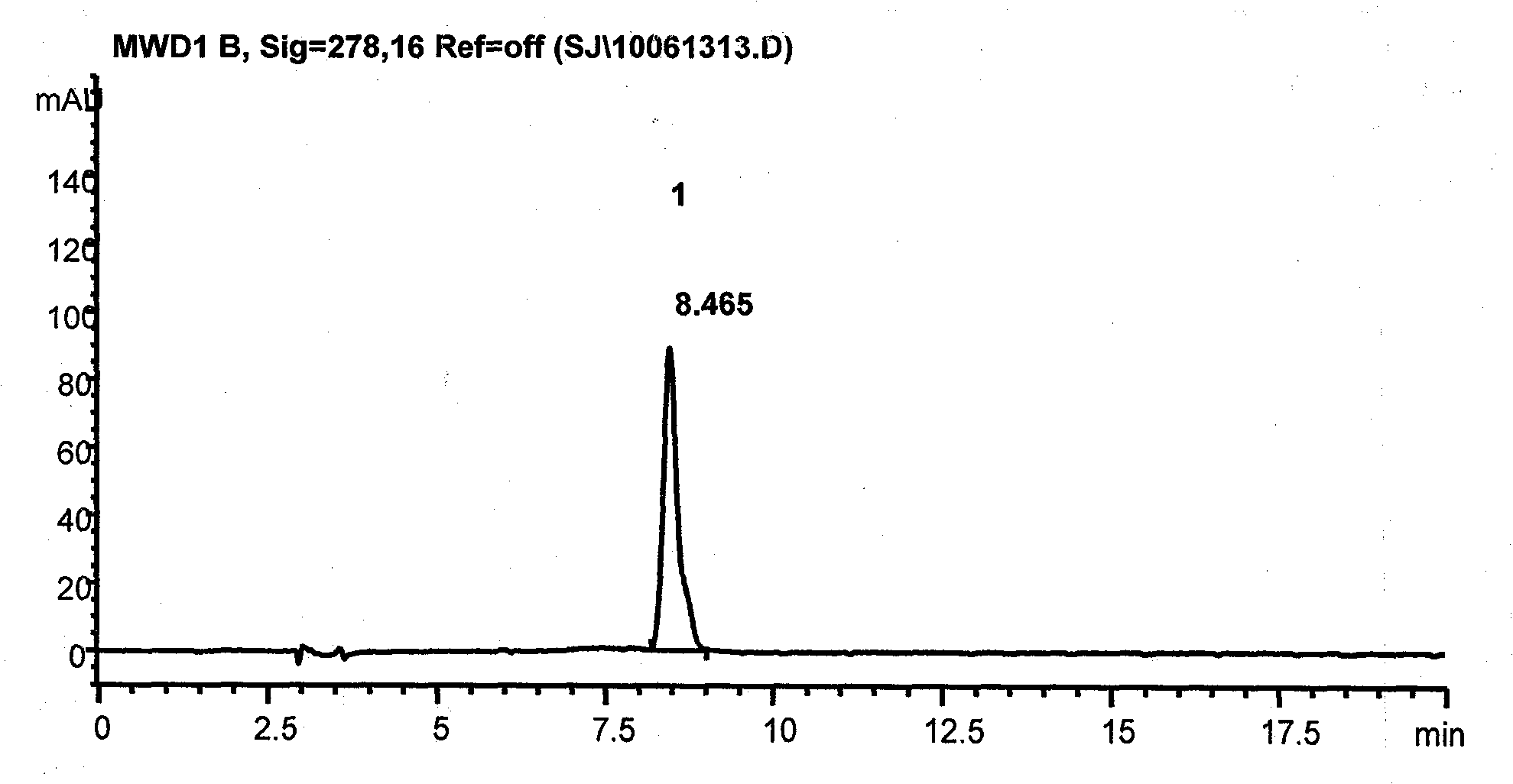

Image

Examples

Embodiment 1

[0070] (1) Extraction: get celandine, cut off, add 12 times, 10 times, 8 times of 70% ethanol to reflux and extract 3 times, combine the extracts, filter, and the filtrate is concentrated under reduced pressure to 1: 1 (the concentration of the medicinal solution is 1 gram medicinal material / ml, the same below), stir and add ethanol until the ethanol content is 80%, stand still, filter, the filtrate is recovered under reduced pressure until there is no alcohol smell, add water to dilute the medicinal liquid concentration to contain 2 gram medicinal material / ml, let stand , filter, discard the insoluble matter, adjust the pH of the filtrate to 1-3, add water to dilute to 1:1, and obtain the standby solution I;

[0071] (2) Resin purification for the first time: take the spare solution I, pass it through the D-101 macroporous resin chromatographic column, and appropriate amount of water (the amount of water is based on not eluting magnolialine, that is, the Molish reaction of the...

Embodiment 2

[0075] (1) Extraction: get celandine, cut off, add 6 times of 60% ethanol to reflux extraction, filter the extract, concentrate the filtrate under reduced pressure to 1:1 (the concentration of the medicinal solution is 1 gram of medicinal material / ml), stir and add ethanol to The ethanol content is 70%, stand still, filter, and the filtrate is recovered under reduced pressure until there is no alcohol smell, and the concentration of the medicinal solution is diluted with water to contain 2 grams of medicinal materials / ml, stand still, filter, discard insolubles, and adjust the pH of the filtrate to 1 to 3, dilute to 1:1 with water to obtain stock solution Ⅰ;

[0076] (2) Resin purification for the first time: take the spare solution I, pass it through the D-101B macroporous resin chromatographic column, water (the amount of water is subject to the eluting of magnolialine, that is, the Molish reaction of the eluent is negative, or Paper spot reaction or thin-layer chromatograph...

Embodiment 3

[0080] (1) Extraction: get celandine, cut off, 10 times of 70% ethanol reflux extraction 3 times, combine the extracts, filter, and the filtrate is concentrated under reduced pressure to 1:1 (the concentration of the medicinal solution is 1 gram of medicinal material / ml, the same below ), stir and add ethanol until the ethanol content is 80%, leave standstill, filter, and the filtrate is recovered under reduced pressure until there is no alcohol smell, and the concentration of the medicinal solution is diluted with water to contain 2 grams of medicinal materials / ml, leave standstill, filter, discard the insoluble substance, the filtrate was adjusted to pH 1-3, and diluted with water to 1:1 to obtain stock solution Ⅰ;

[0081] (2) The first resin purification: take the spare solution I, pass it through the XDA-1 macroporous resin chromatographic column, and appropriate amount of water (the amount of water is subject to the eluting of magnolialine, that is, the Molish reaction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com