Finger protecting ring of sewing machine

A sewing machine and steel wire technology, applied in sewing machine protection devices, sewing machine components, sewing equipment, etc., can solve problems such as loss, human injury to the economy, and finger stabs, saving time, increasing production, and avoiding human injury and economic loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

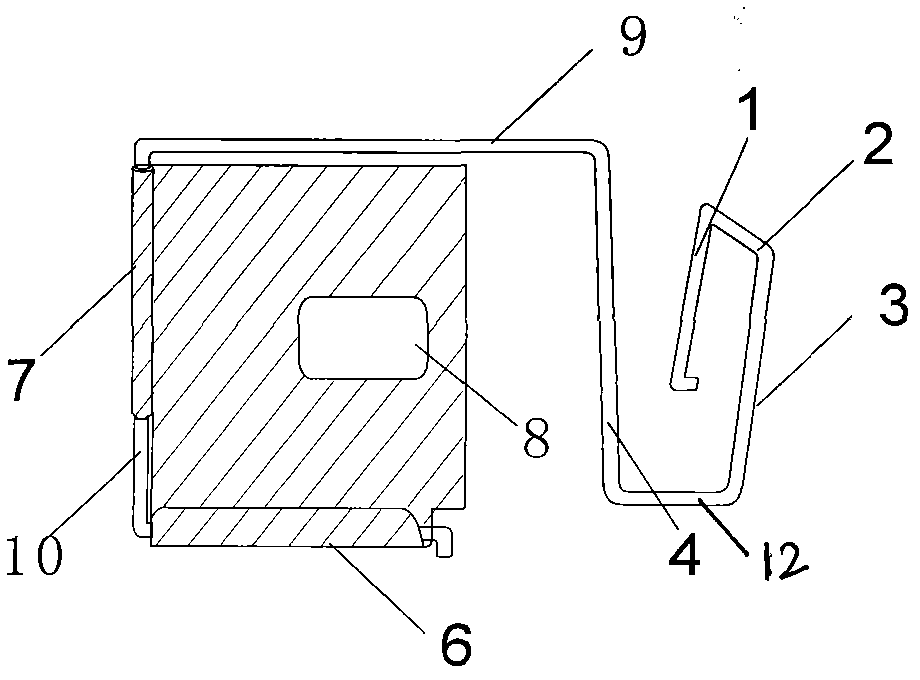

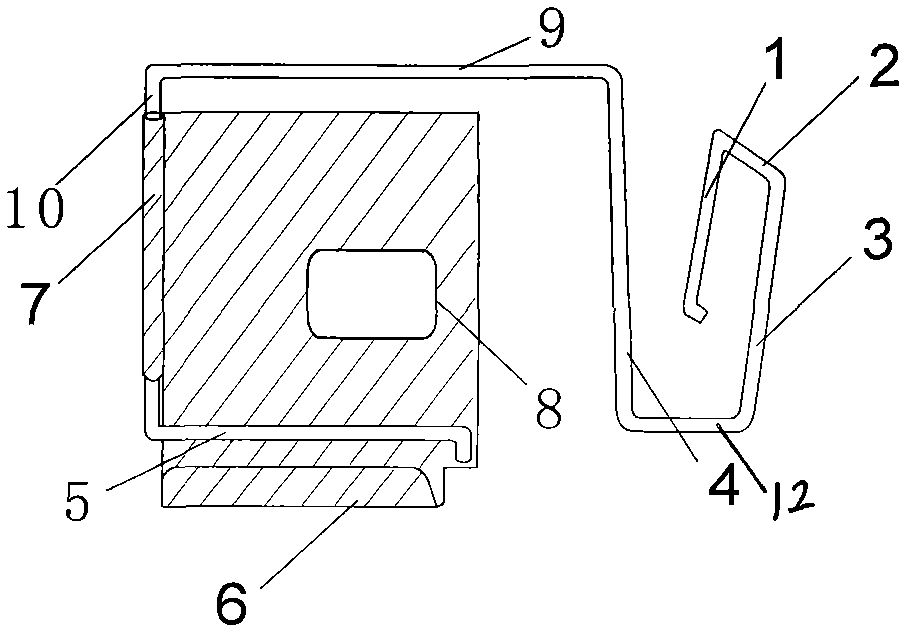

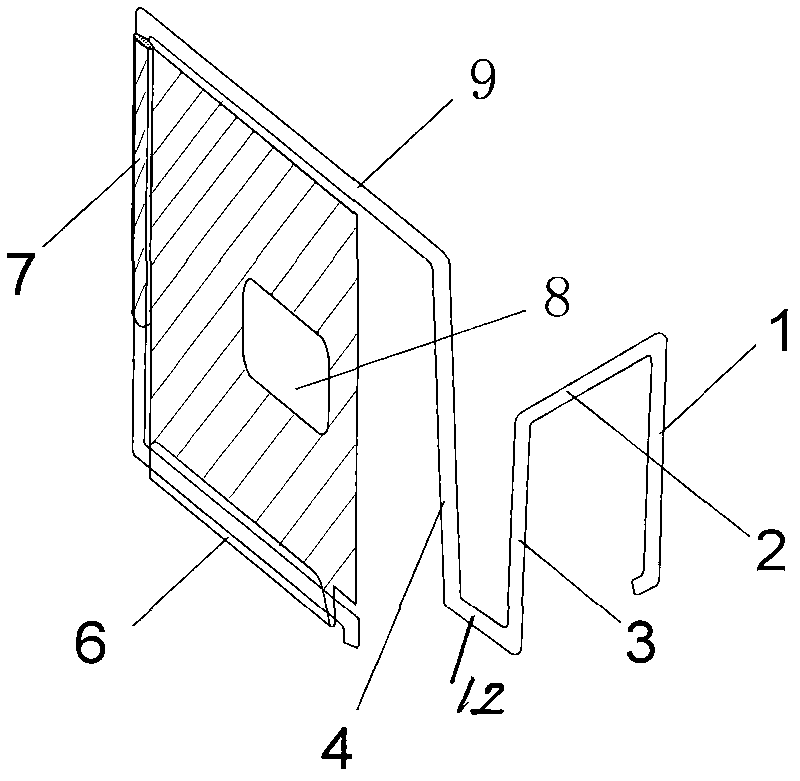

[0013] exist figure 1 , 2 picture, image 3 , Figure 4 In the embodiment, the steel wire is bent into the first section steel wire 1, the second section steel wire 2, the third section steel wire 3, the fourth section steel wire 12, the fifth section steel wire 4, the sixth section steel wire 9, and the seventh section steel wire 10. The eighth section of steel wire 5 becomes a connector of different shapes; the first section of steel wire 1, the second section of steel wire 2 and the third section of steel wire 3 after bending become an inverted "冂" shape; the third section after bending Steel wire 3, the fourth section steel wire 12 and the fifth section steel wire 4 become "U" shaped steel wire parts; the fifth section steel wire 4, the sixth section steel wire 9, the seventh section steel wire 10 and the eighth section steel wire 5 become Square frame; the first folded edge 7 and the second folded edge 6 of the flat plate 11 are installed on the square steel wire frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com