Drying machine and laundry dryer

A laundry dryer and drying technology, which is applied to other washing machines, washing machines with containers, household clothes dryers, etc., can solve the problems of reduced power consumption, no consideration of drying methods, etc., and achieve the effect of suppressing uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below using the drawings.

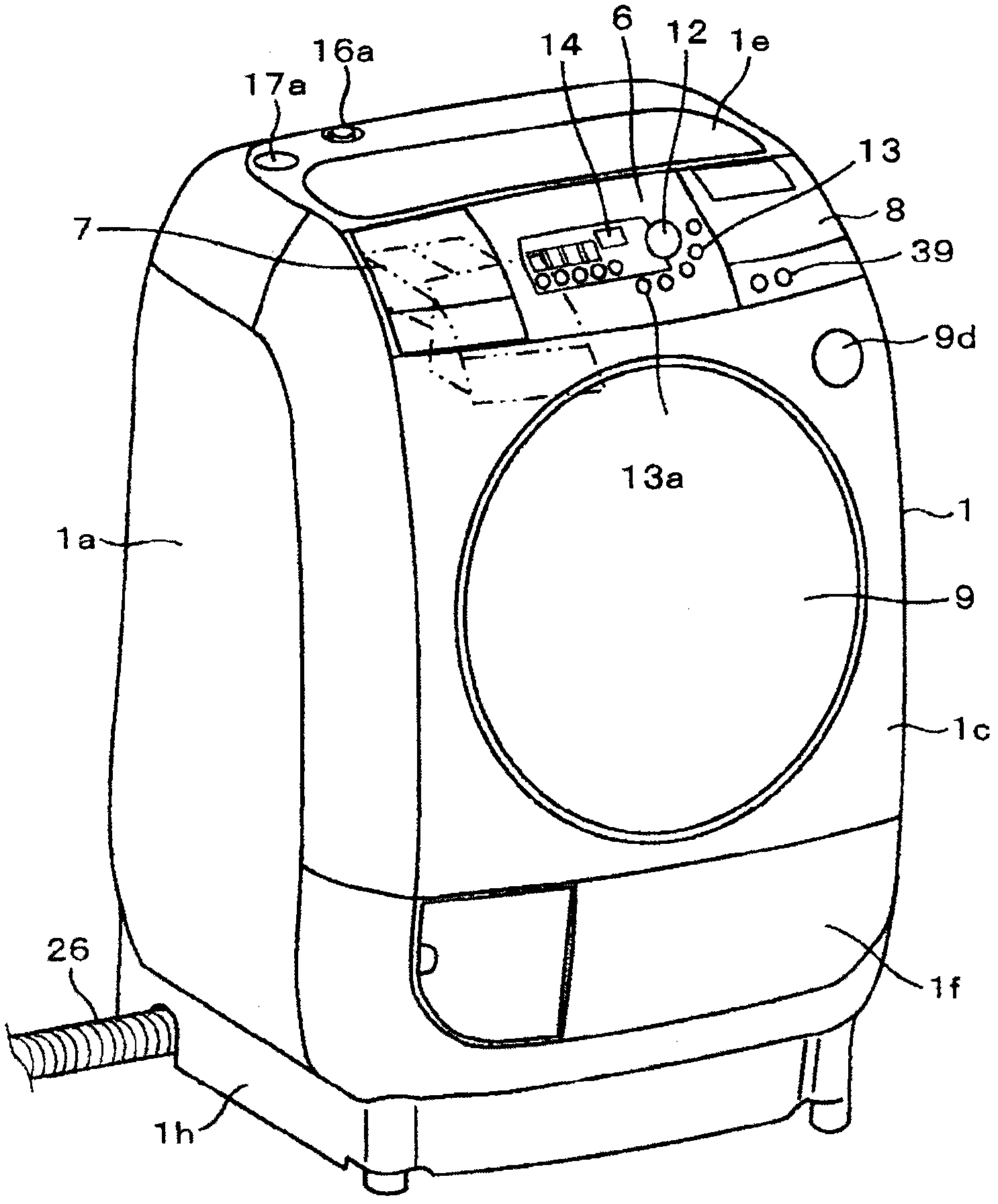

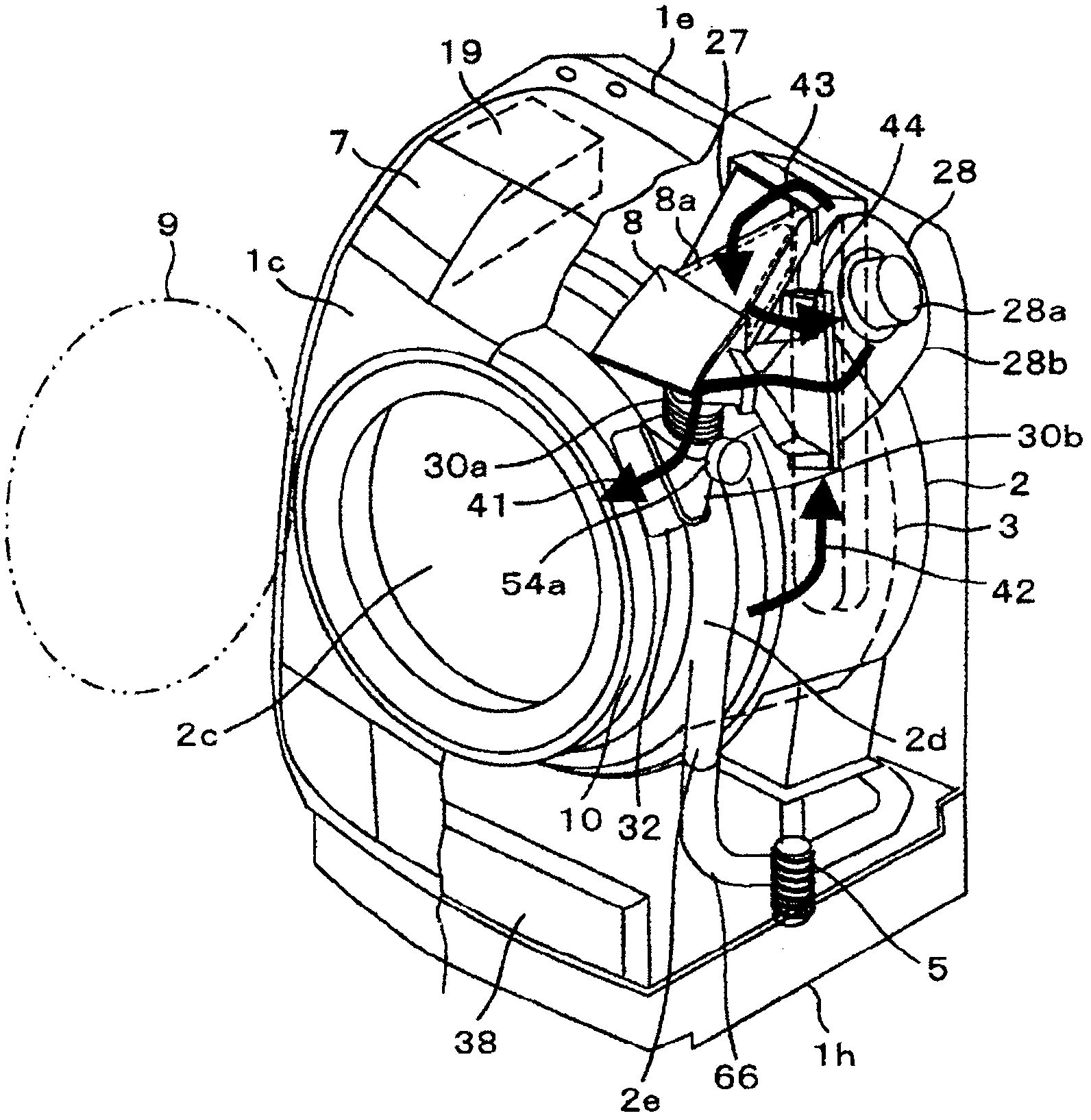

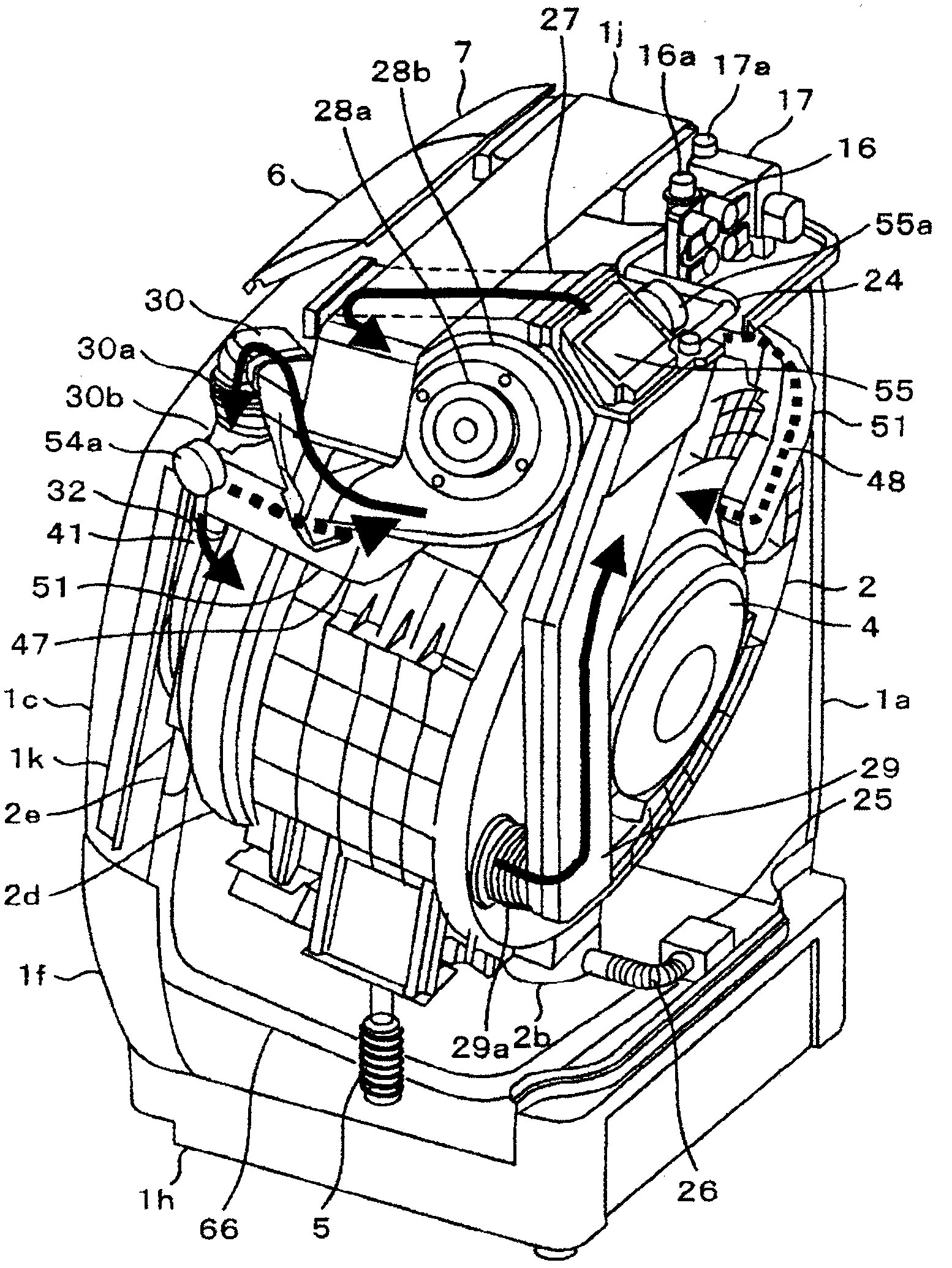

[0033] figure 1 It is an external perspective view of a drum-type washing-drying machine according to an embodiment example of the present invention, figure 2 It is a perspective view viewed obliquely from the front by partially cutting the box to show the internal structure, image 3 It is a perspective view viewed obliquely from the rear by partially cutting the box to show the internal structure, Figure 4 It is a rear view with the rear cover removed to show the internal structure, Figure 5 is a side view showing the internal structure.

[0034] Reference numeral 1 is a box body constituting the outer contour. The box body 1 is mounted on a base 1h, and is composed of left and right side panels 1a, 1b, a front cover 1c, a rear cover 1d, an upper cover 1e, and a lower front cover 1f. The left and right side panels 1a, 1b are combined with a U-shaped upper reinforcement 1j, front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com