Planarized magnetic recording disk with pre-patterned surface features and secure adhesion of planarizing fill material and method for planarizing the disk

A magnetic recording, flat technology, applied in the direction of pattern record carrier, magnetic recording layer, different record carrier forms, etc., can solve the problem of non-magnetic filling material peeling off and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

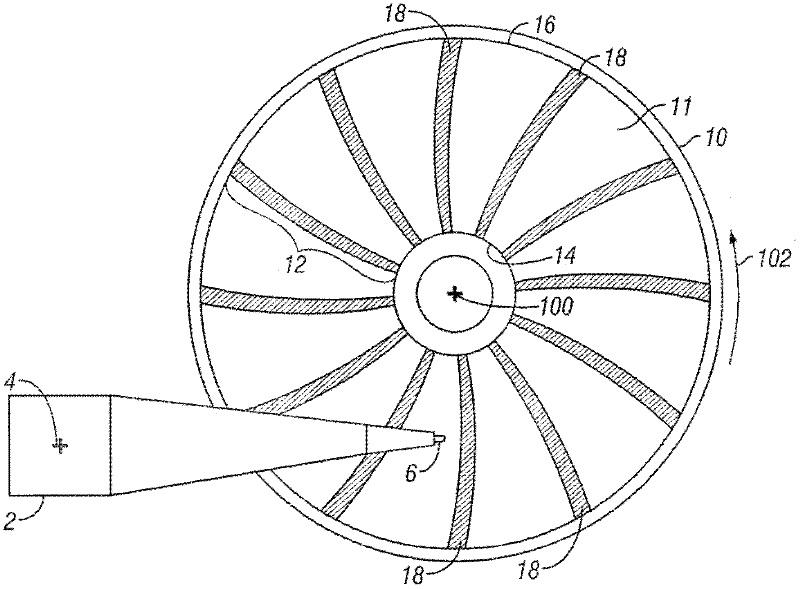

[0017] figure 1 A disk drive with a rotary actuator 2 and a rigid magnetic recording disk 10 is shown, the magnetic recording disk 10 having pre-patterned surface features formed on the surface 11. The surface features include at least pre-patterned servo blocks in angularly spaced servo sectors 18. The disk 10 rotates in the direction 102 about the central axis 100. The surface 11 has an endless data band 12 which is defined by an inner diameter (ID) 14 and an outer diameter (OD) 16. The part of the data zone between the servo sectors 18 is used to store user data and contains circular data tracks. Each data track is generally divided into multiple physical data sectors. The disc 10 may be a DTM disc. In this case, the circular data tracks are discrete radially spaced high tracks separated by a recessed guard band. Except for the servo blocks in the servo sector 18, the high tracks The road and recessed guard band form the surface features. The disk 10 may also be a BPM dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap