Lens and semiconductor light-emitting element module using same

A light-emitting element module and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor devices, optical elements, etc. of light-emitting elements, and can solve problems such as the inability to reduce the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

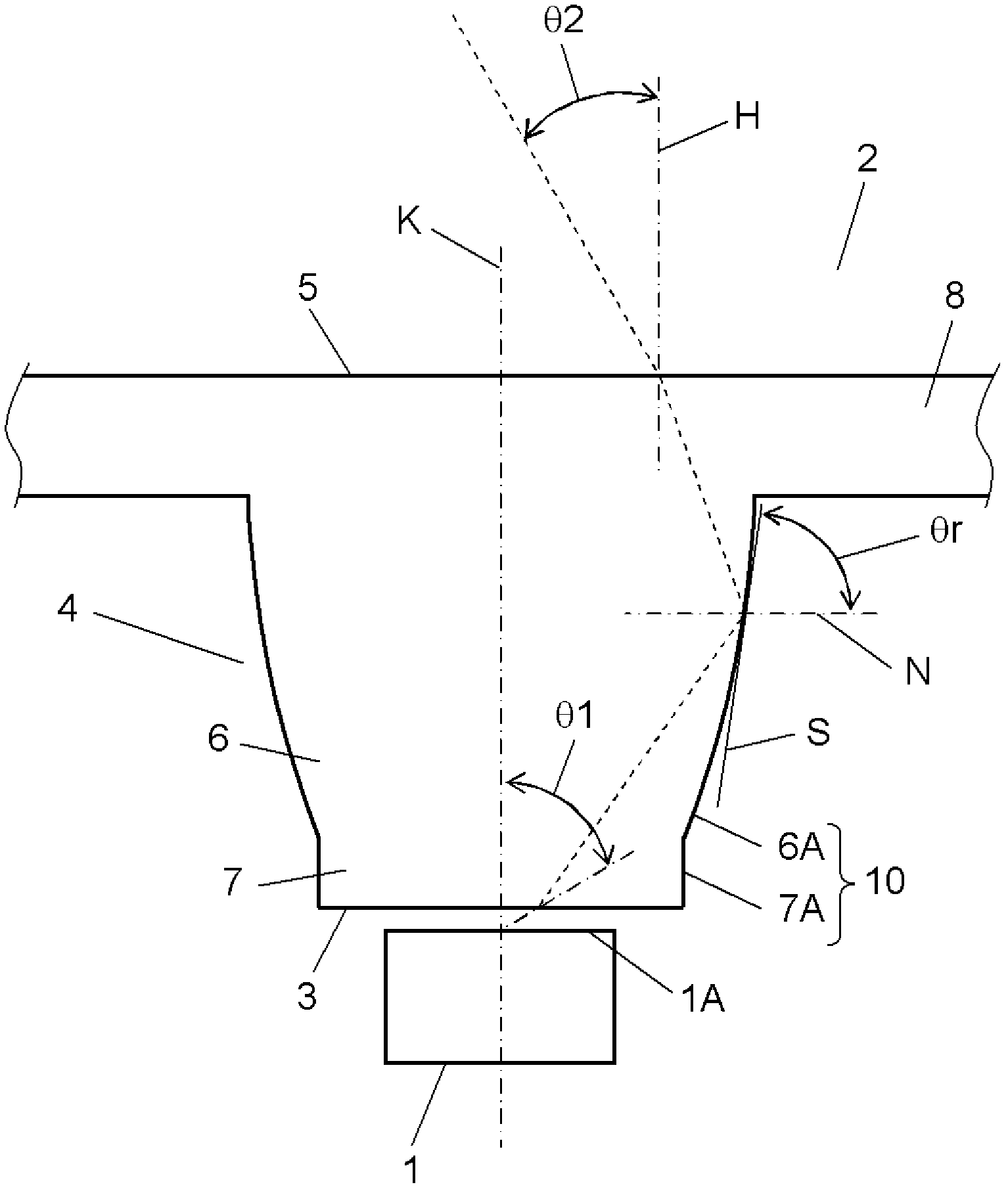

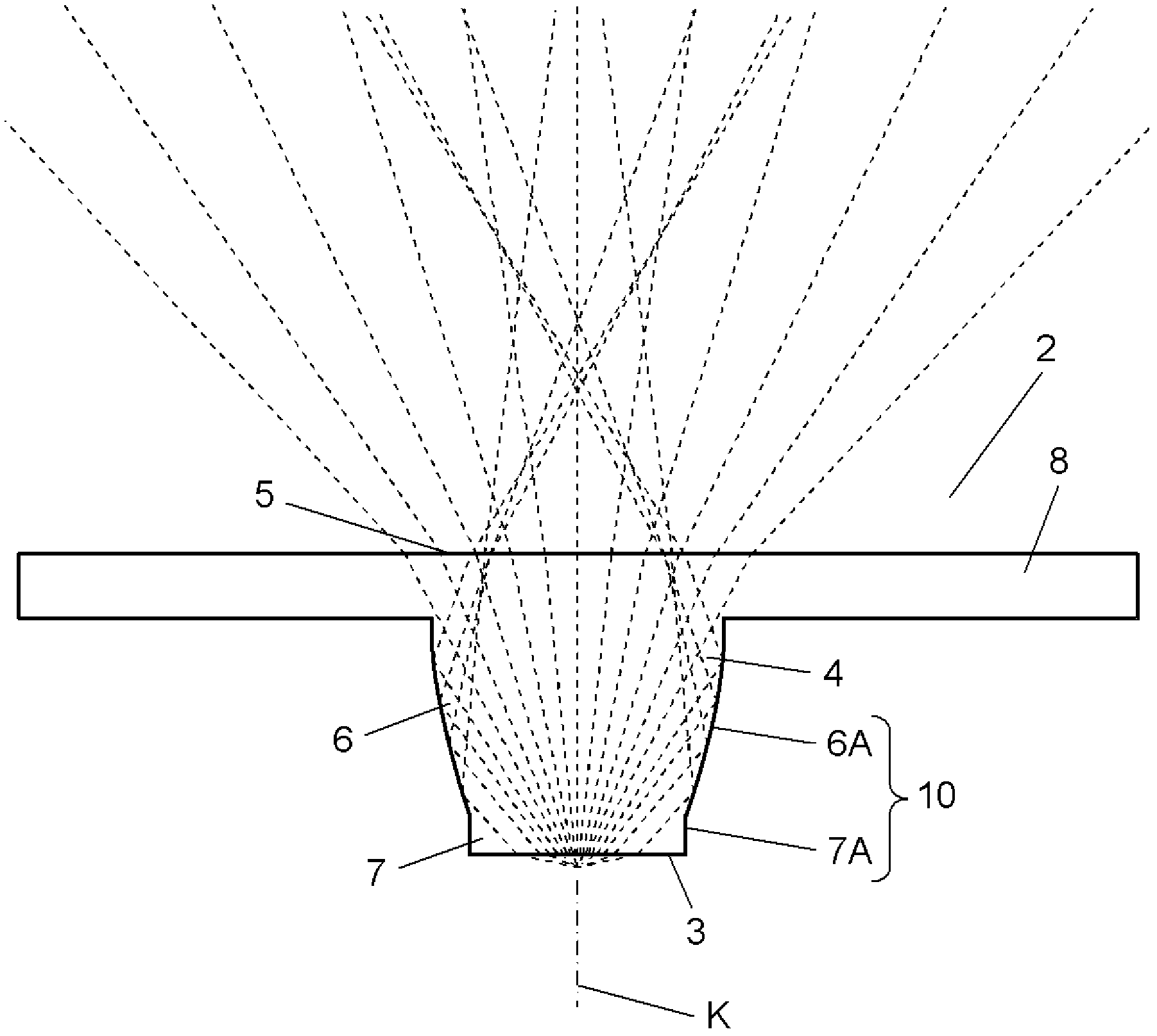

[0020] figure 1 It is an enlarged side view showing the structure of the semiconductor light emitting element module according to the embodiment of the present invention. figure 2 yes means figure 1 An explanatory diagram of the alignment of the lens of the semiconductor light emitting element module shown. Figure 3A , Figure 3B , Figure 3C respectively figure 2 Top view, left side view, front view of the lens shown. This semiconductor light emitting element module includes, for example, a light source (point light source) 1 composed of, for example, a light emitting diode (LED) mounted on a substrate (not shown), and a lens arranged in front of one side of the light emitting surface 1A of the light source 1. 2. The light source 1 composed of chip-type LEDs has a reflector. The shape of the reflector is circular in plan view, and may also be elliptical, square or polygonal. Such a semiconductor light emitting element module is incorporated in a mobile phone or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com