Through-wiring board and method of manufacturing same

A technology for wiring substrates and manufacturing methods, which is applied in the fields of printed circuit manufacturing, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., and can solve problems such as narrowing of electrode intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

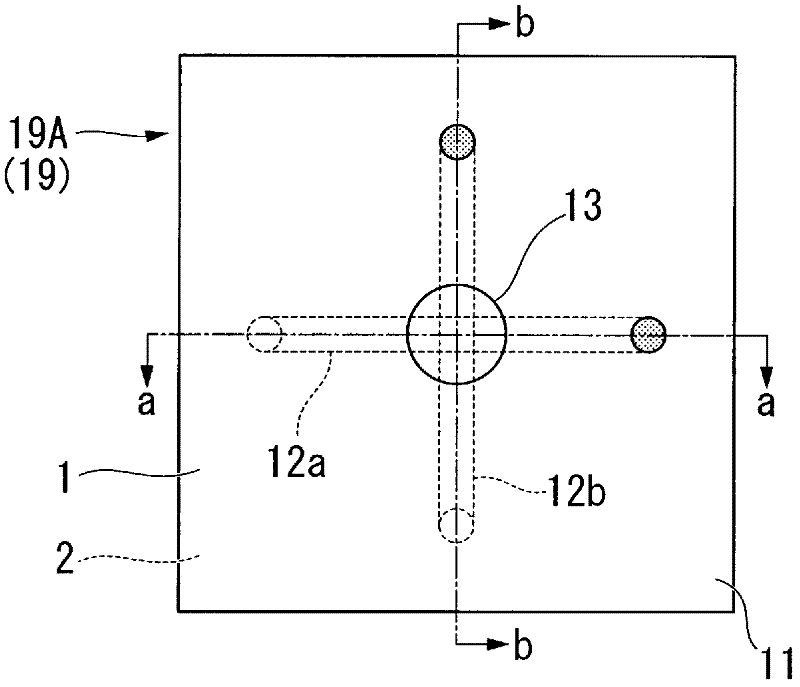

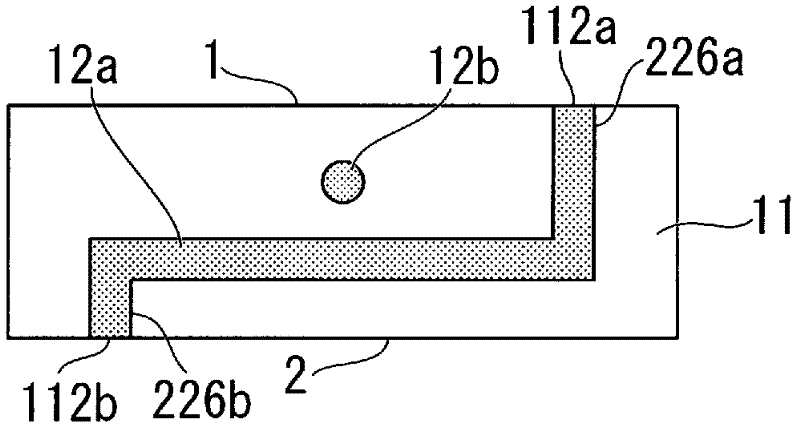

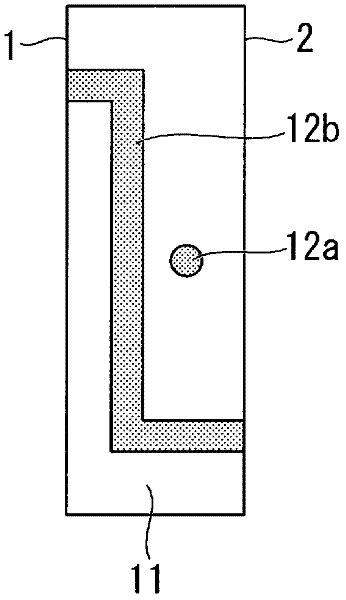

[0061] Figure 1A ~ Figure 6C It is a plan view and a cross-sectional view showing interposer substrate 19 according to the embodiment of the present invention. As shown in each drawing, through-wiring substrate 19 according to the embodiment of the present invention includes a plurality of through-wiring wirings penetrating through two or more surfaces constituting single substrate 11 . In addition, the through-wirings of each through-wiring substrate 19 are separated from each other, and have at least one overlap when viewed from the overlapping direction of the two surfaces (first surface and second surface) forming the front and rear surfaces of the substrate 11 . The overlapping portion 13 (intersection). That is, the through-wirings of the through-wiring substrate 19 are separated from each other, and at least one overlapping portion 13 is provided in plan view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com