Unit solid-borne noise treatment device

A technology for solid sound and generator set, which is applied in the field of solid noise control and noise treatment of generator set, can solve the problems of rust prevention treatment and regular maintenance, which have a certain workload, less effect, and hinder solid noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

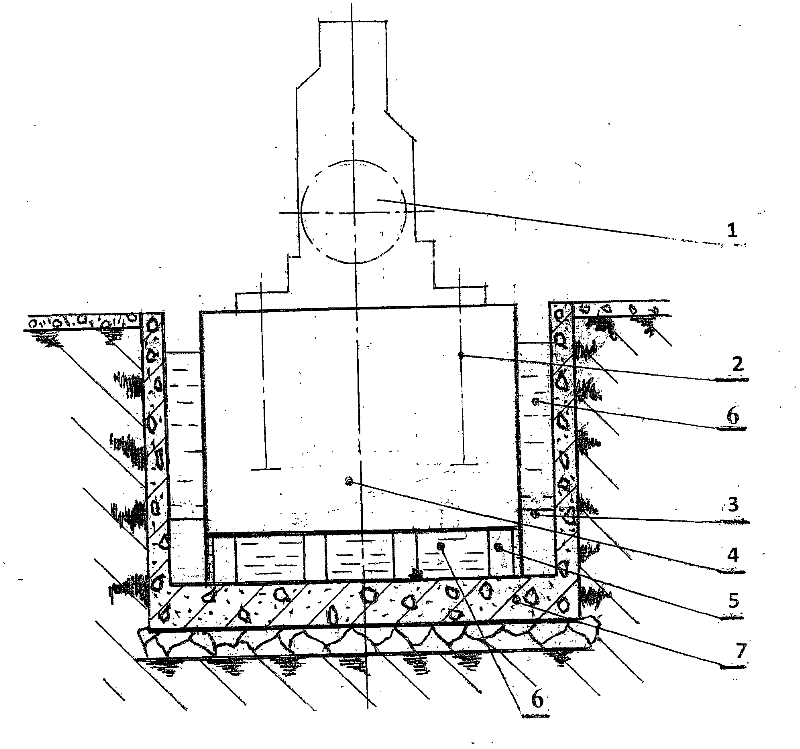

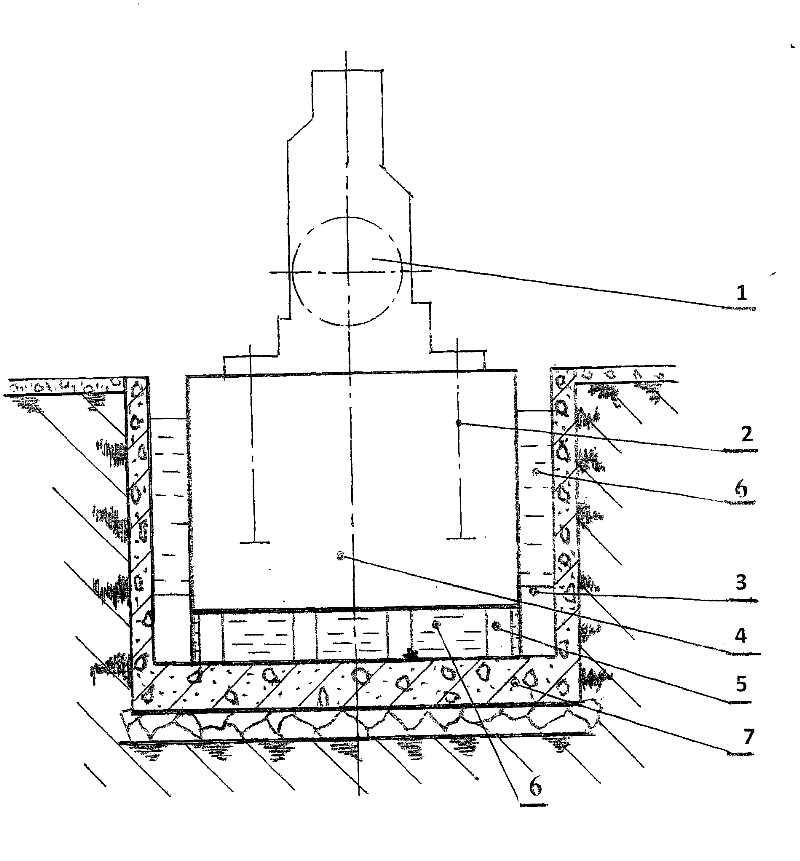

[0012] Such as figure 1 The unit solid sound noise control technology shown is composed of diesel generator set 1, cement foundation 4, foundation screw 2, foundation limit device 3, vibration damping and sound insulation pad 5, foundation vibration isolation seat 7, and isolation water 6 , is characterized in that: the diesel generator set 1 is fixed on the cement foundation 4, and is fastened by foundation screws 2; The pad 5 is isolated up and down from the base vibration isolation seat 7 . The vibration-absorbing and sound-insulating pad 5 is preferably separated by a 3-5 mm stainless steel plate between the upper and lower rubber blocks; the four corners of the cement foundation 4 are provided with a foundation limiting device 3 and the foundation vibration isolation seat 7 is isolated from the left and right. The base limiting device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com