Heating type cold/hot dual-purpose water valve

A dual-use, heating-type technology, applied in the valve heating/cooling device, valve details, valve device and other directions, can solve the problem that a valve can not let cold and heat, and achieve safe and reliable performance, manual water temperature control , the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

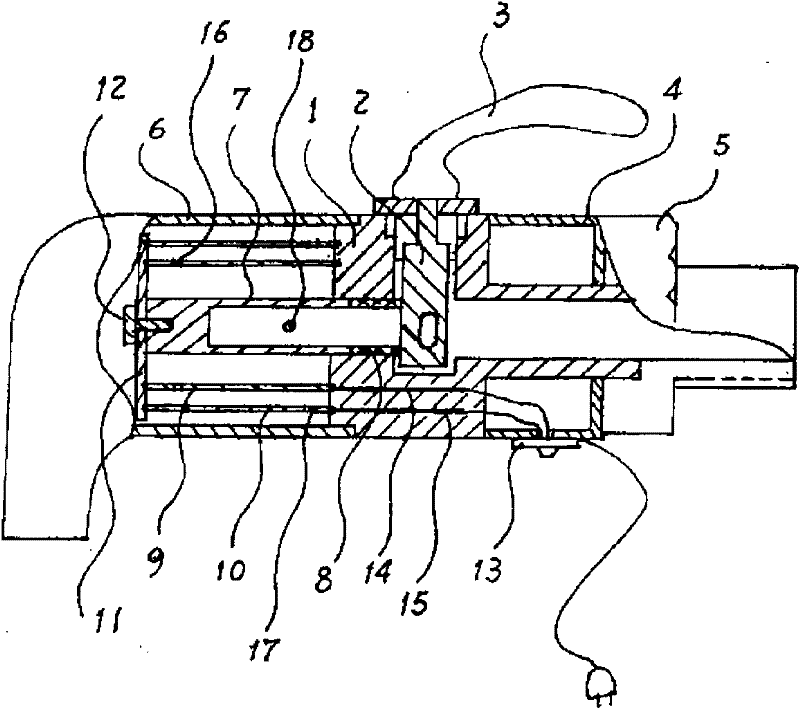

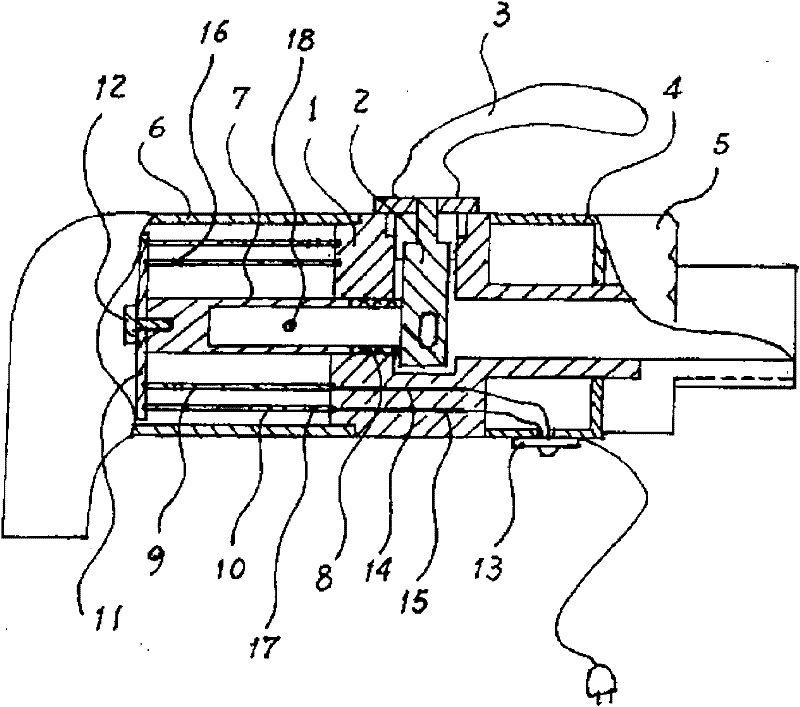

[0007] figure 1 The hot and cold dual water valve shown is a new type of water valve improved on the basis of the drain valve formed by the existing valve body 1, spool 2, handle 3, retainer 4, bolt 5 and shell 6. It is that the seal ring 8 and the pipe support 7 are sequentially arranged in the channel of the valve body 1 on the water outlet side, and the side of the pipe support 7 close to the seal ring 8 is a cavity body, and a water flow channel 18 is provided on the cavity body part. The outside of the pipe pillar 7 is respectively covered with inner and outer sleeves 9, 10, and the two ends of the inner and outer sleeves 9, 10 are respectively inserted into the valve body 1 and the corresponding ring groove of the gland 11. The gland 11 is fixedly connected to the pipe pillar 7 via screws 12 . The DC power supply is connected with the inner and outer casings 9 and 10 respectively through the switch 13 and the terminal posts 14 and 15. Water flow channels 16 and 17 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com