Tire vulcanization mold manufacturing method and tire vulcanization mold

一种轮胎硫化、制造方法的技术,应用在轮胎硫化用模具的制造以及轮胎硫化用模具领域,能够解决加工工序变多、制造所需的时间变长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

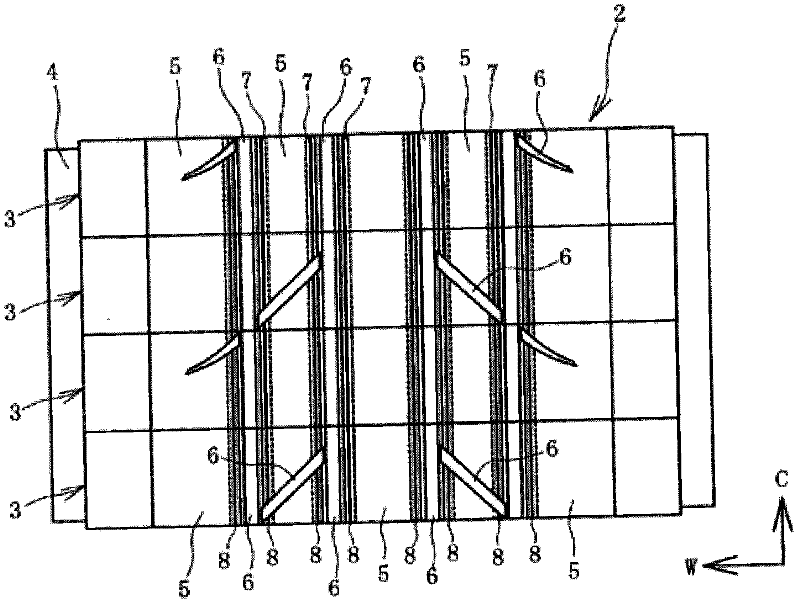

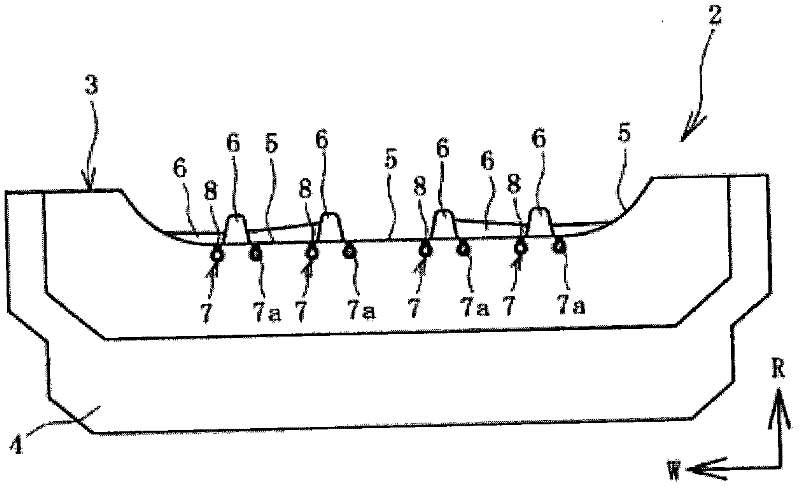

[0048] Next, the manufacturing method of the mold for tire vulcanization and the mold for tire vulcanization of the present invention will be described based on the illustrated embodiment. C arrows, R arrows, and W arrows shown in the figure indicate the circumferential direction, radial direction, and width direction of the raw tire inserted into the vulcanizing mold to be vulcanized, respectively.

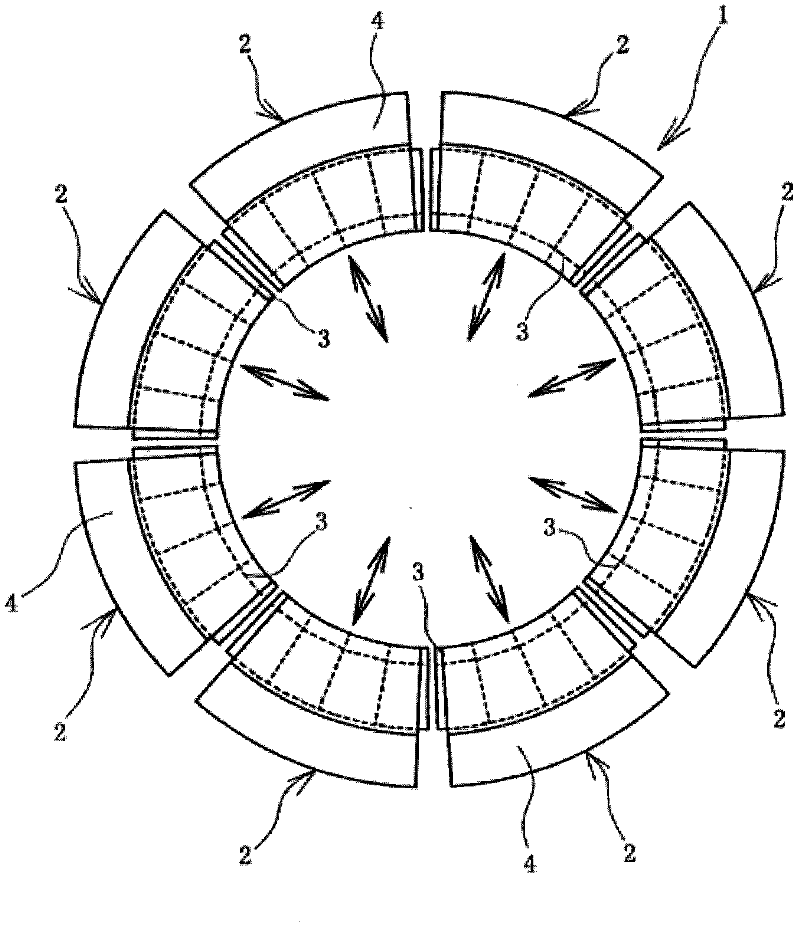

[0049] Such as figure 1 As shown, the mold 1 for tire vulcanization of the present invention (hereinafter referred to as the mold 1 ) is formed as a combined mold composed of a plurality of sector parts 2 combined in a ring shape. Such as figure 2 , 3 As shown, each fan-shaped part 2 is composed of a plurality of segments 3 and a back block 4, and is installed on the back block 4 in a state where adjacent segments 3 are closely attached. The inner peripheral side surface of each segment 3 forms a tire forming surface 5 . Groove forming protrusions 6 for forming tire grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com