Lock nut

A technology for locking nuts and nuts, applied in the direction of locking fasteners, screws, nuts, etc., can solve the problem of axial displacement of internal threads without washers and nut bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

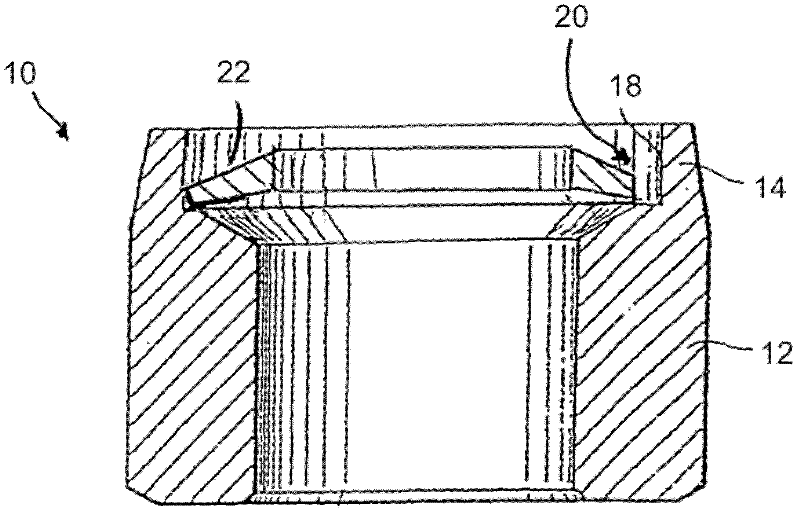

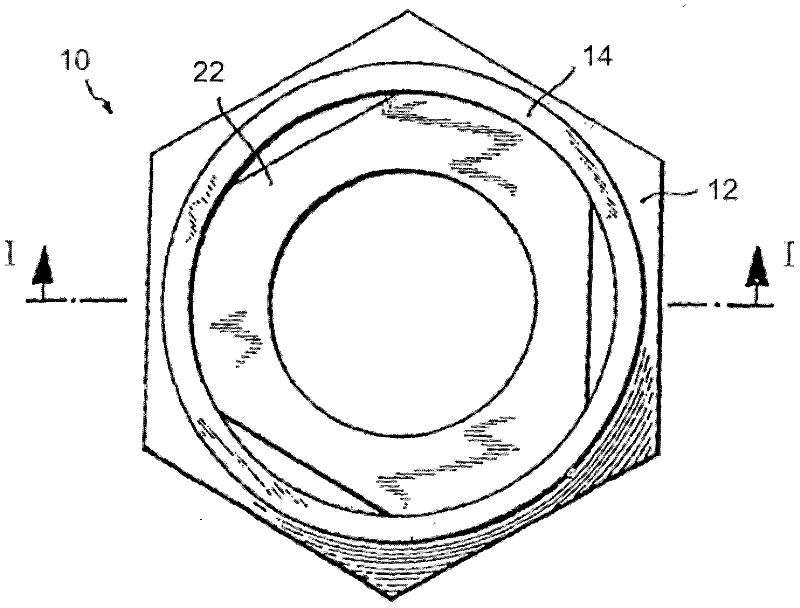

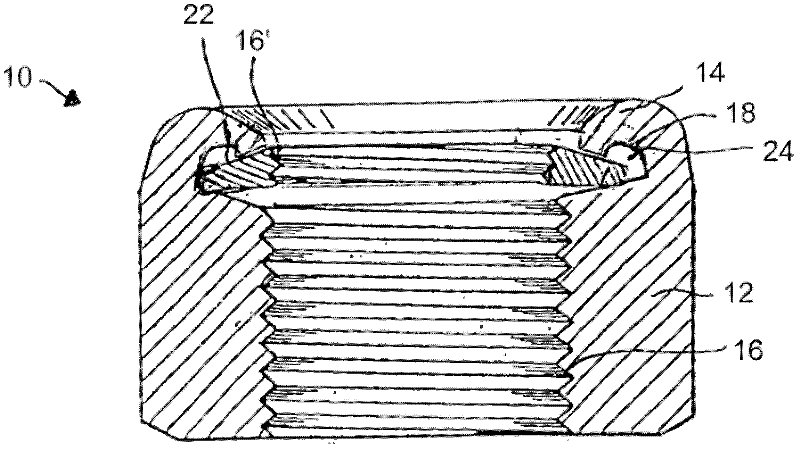

[0029] as attached Figure 1 to Figure 4 As shown, the union nut 10 according to the invention has, on one end side, a nut body 12 with a concentric neck-shaped projection 14 . The union nut 10 is designed, for example, as a hex nut made of steel and in its image 3 and Figure 4 The finished state shown has an internal thread 16 , which is referred to below as “nut thread” 16 . The inner edge 18 of the neck-shaped projection 14 is displaced outward relative to the inner diameter of the thread of the union nut 10 in order to form a socket 20 for a fastening washer 22 . The fastening washer, hereinafter also referred to simply as washer, is made of metal, preferably of elastic material, such as spring steel or spring strip steel. exist Figure 1 to Figure 4 In the embodiment shown, the washer 22 has three segment-shaped depressions, wherein the washer is fastened in the lock nut 10 in its circumferential region remaining between these depressions, as formed by the prior art o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com