Self-centering power chuck of circular arc-shaped groove

An arc groove and self-centering technology, applied in the direction of the chuck, can solve the problems of high processing cost, small claw stroke, complex structure, etc., and achieve the effect of low processing cost, large claw stroke, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Referring to the accompanying drawings, the arc groove self-centering power chuck of the present invention will be described in detail below.

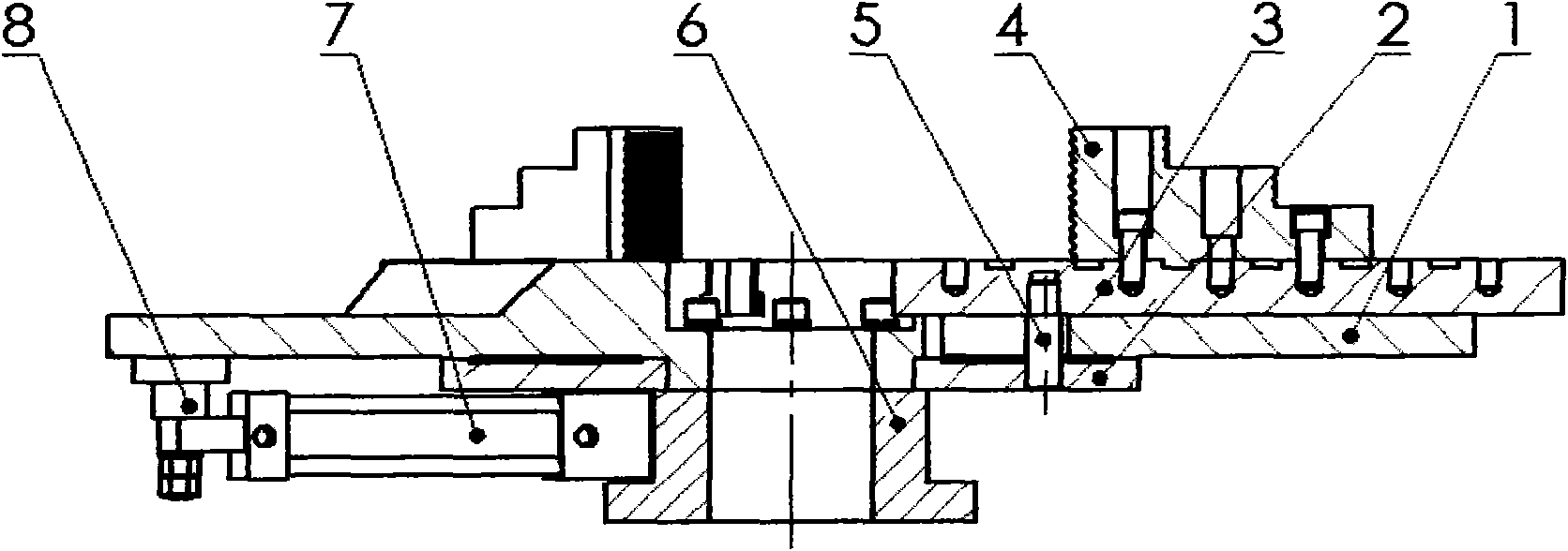

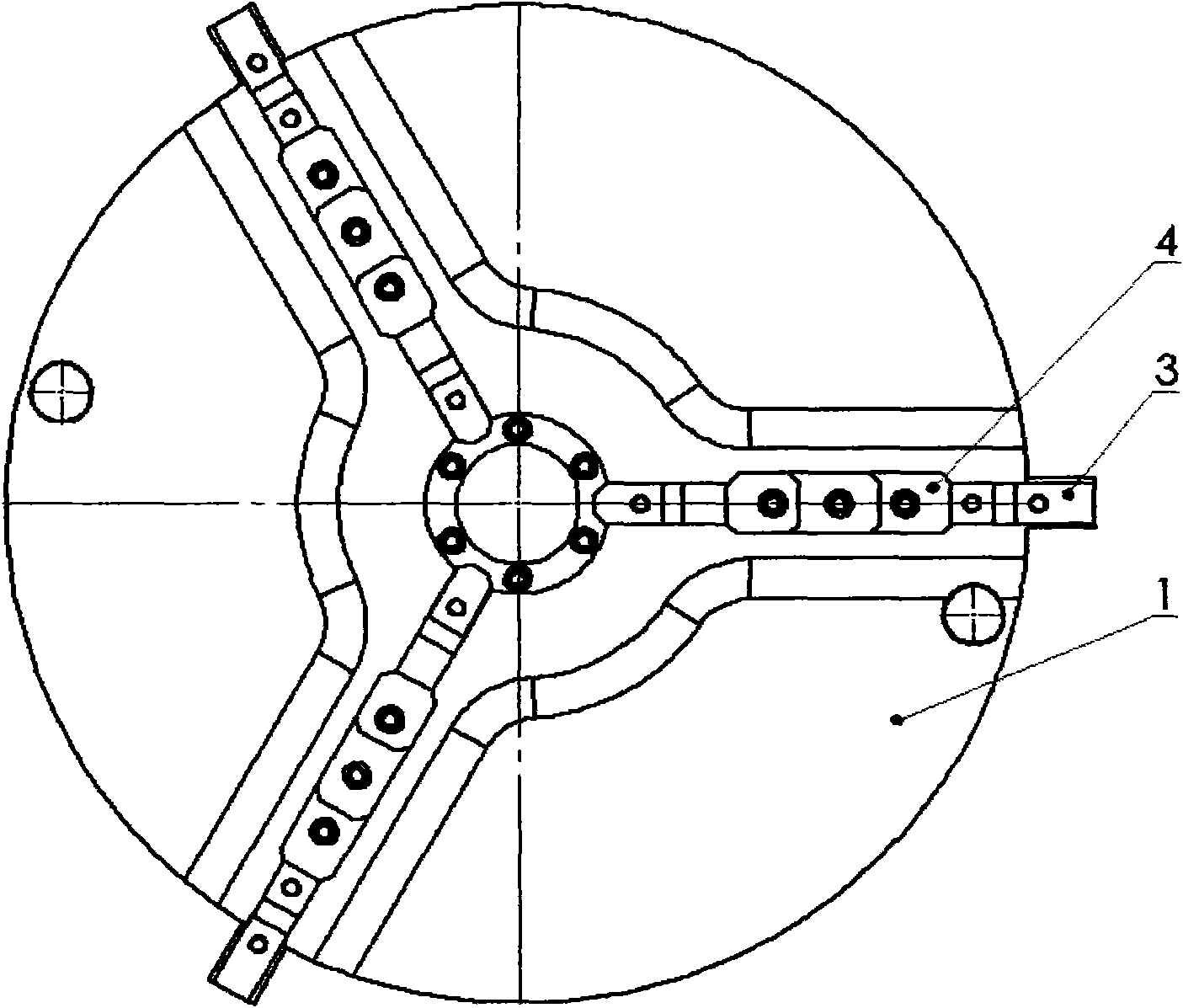

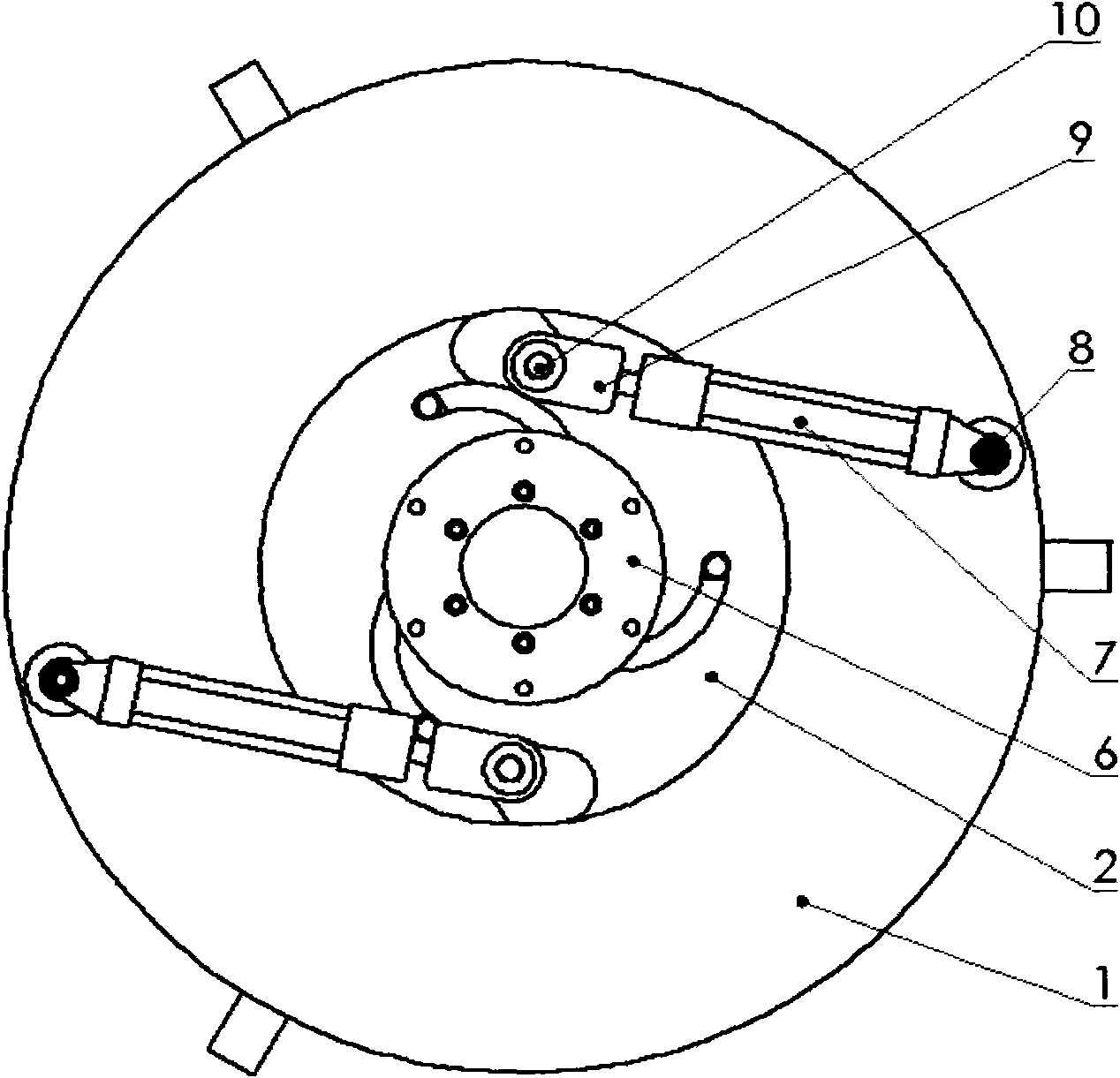

[0020] The arc groove self-centering power chuck of the present invention is composed of a chuck body 1, a face plate 2, a trapezoidal slider 3, a claw 4, a pin shaft 5, a connecting flange 6, an oil cylinder 7, an oil cylinder shaft 8, a joint 9, and a joint shaft 10 composition. The faceplate 2 is installed closely below the chuck body 1 and is coaxial with the chuck body 1, the chuck body 1 and the faceplate 2 can rotate mutually, and the trapezoidal slider 3 is installed in the trapezoidal groove on the chuck body 1 and can Sliding in the trapezoidal groove, the pin shaft 5 is fixed under the trapezoidal slider 3, and inserted into the linear long slot hole of the chuck body 1, and also inserted into the arc slot hole of the face plate 2, and the claw 4 can be fixed on the trapezoidal slot. At different positions on the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com