Flexible gripping device

A grasping device and flexible technology, applied in the field of grasping devices, can solve problems such as the inability to automatically align the center position of the workpiece to be picked and placed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The flexible grasping device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

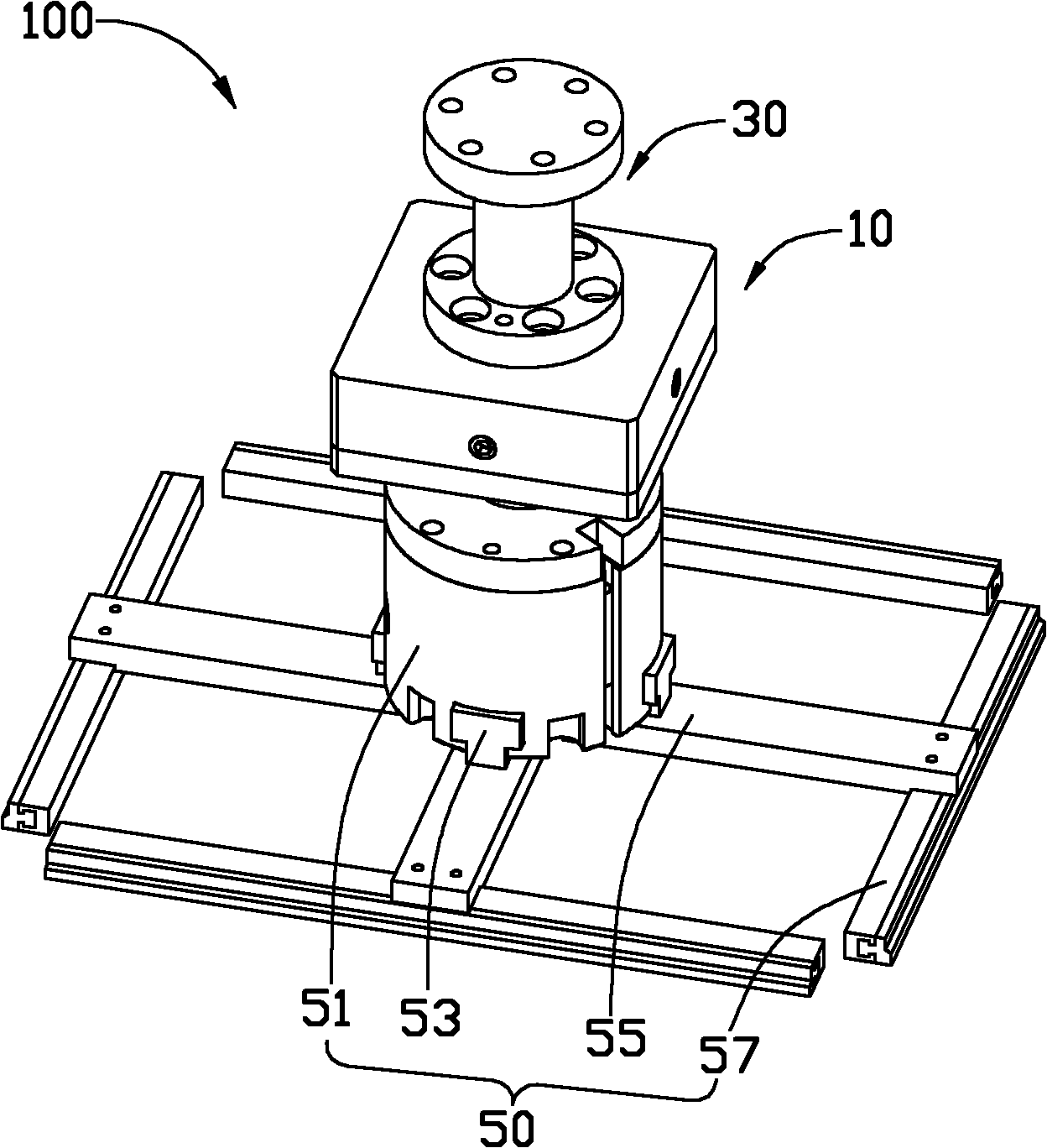

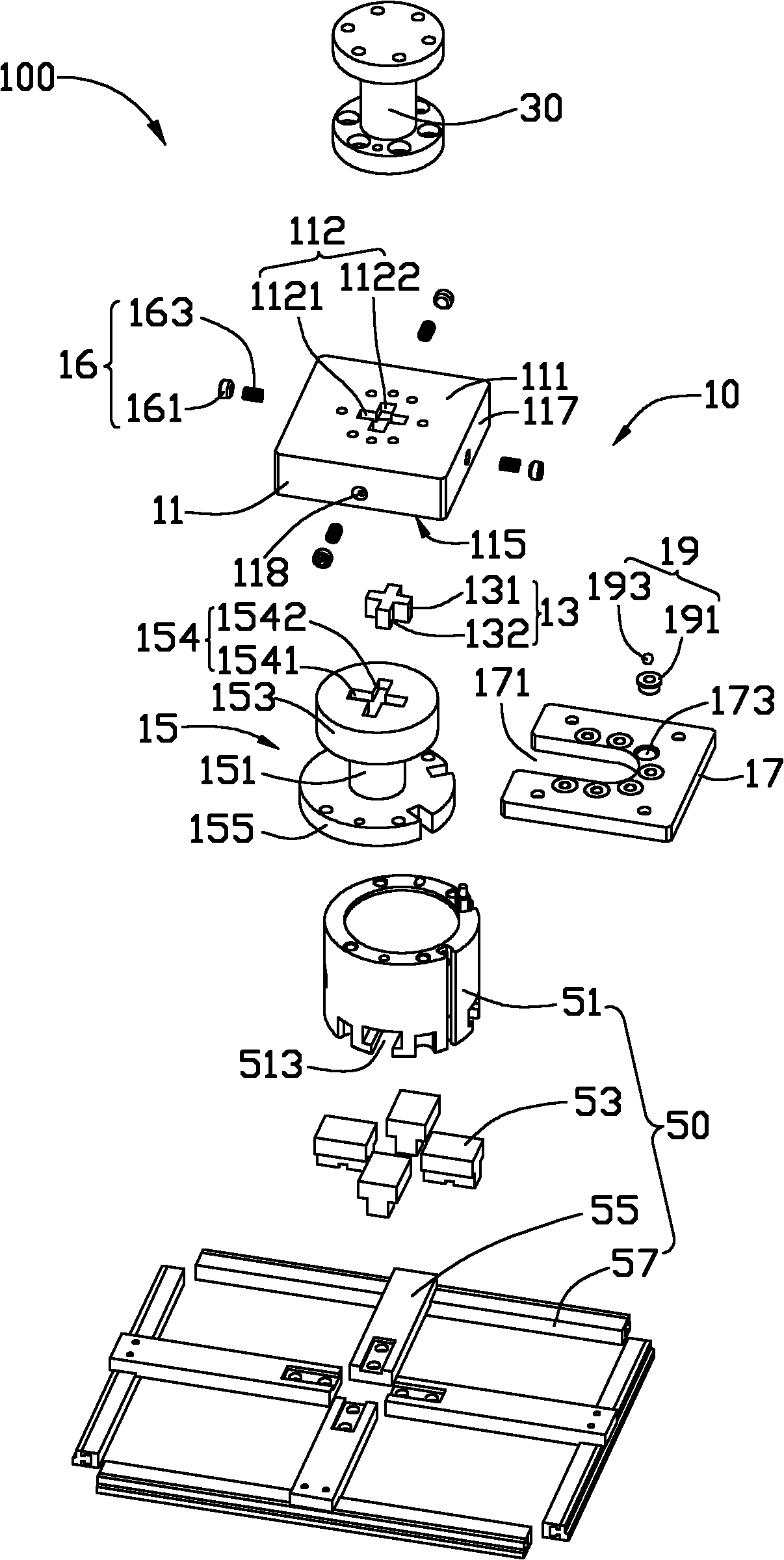

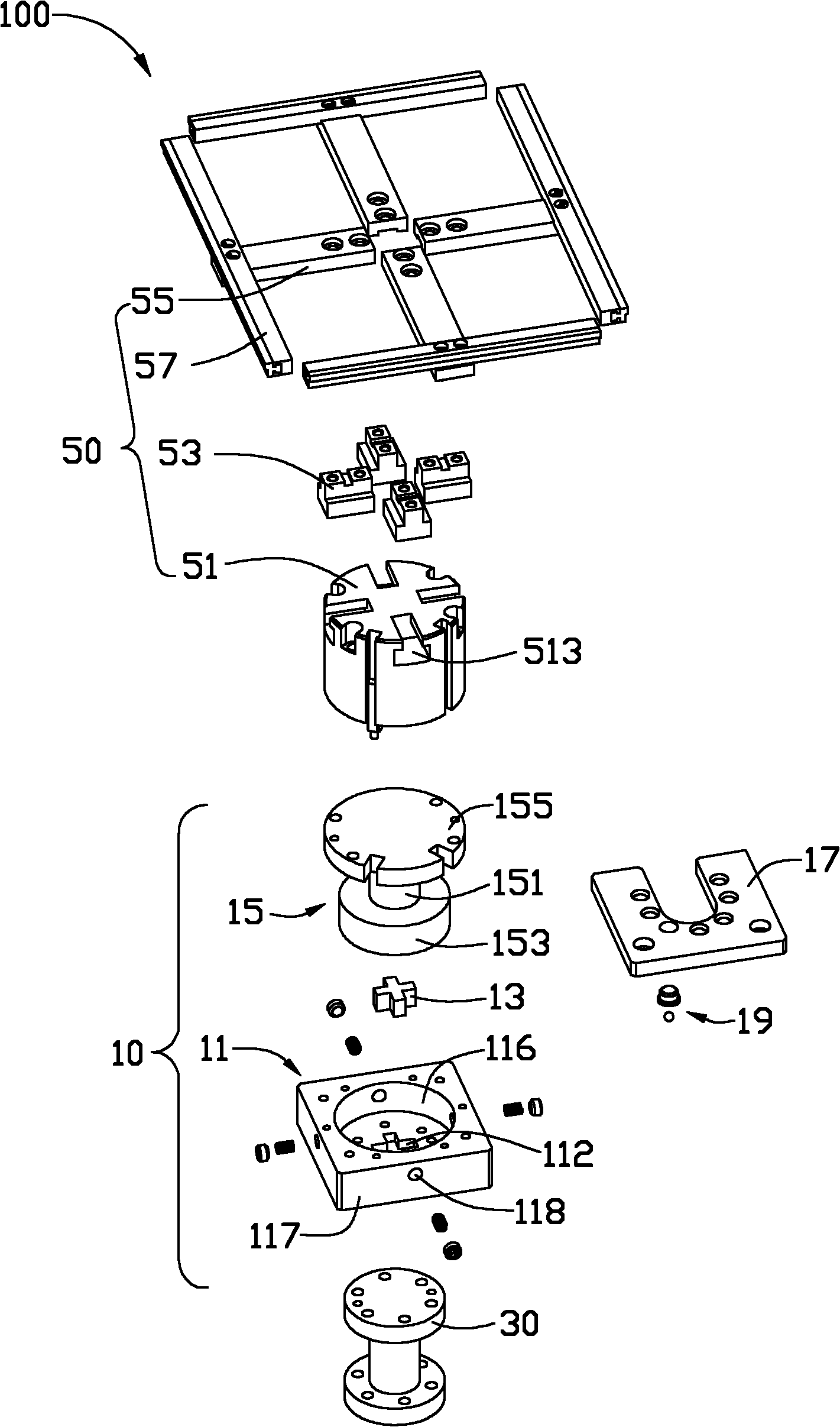

[0014] see figure 1 , The flexible grabbing device 100 includes a flexible mechanism 10, a connecting piece 30 and a gripper assembly 50. One end of the connecting piece 30 is affixed to the flexible mechanism 10, and the other end is used for affixing to the mechanical arm of the robot or the drive shaft of the driving device. The jaw assembly 50 is fixedly connected to the other end of the flexible mechanism 10 relative to the connecting member 30 for grabbing a workpiece (not shown).

[0015] Please also refer to figure 2 and image 3 , The flexible mechanism 10 includes a flexible seat 11 , a sliding block 13 , a sliding shaft 15 , an adjusting component 16 , a fixing plate 17 and a lubricating component 19 . The flexible seat 11 is substantially rectangular plate-shaped, including a top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com