Agitating lorry constant-speed control method

A technology of constant speed control and mixer truck, which is applied to control devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of high cost and unsuitable popularization of constant speed control methods, and achieve convenient operation, quality assurance, and reduction of cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

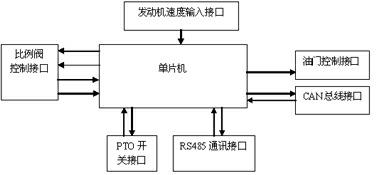

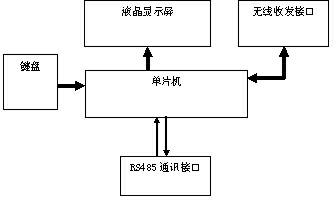

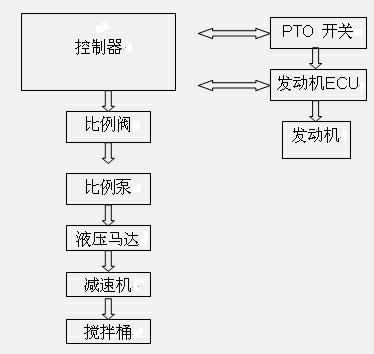

[0019] like image 3 As shown, a constant speed control method for a mixer truck provided by the present invention includes the following steps:

[0020] Step 1. The user inputs the target speed, industrial and mining data into the controller through the main control panel, and the controller combines the target speed with the formula Calculate the current output to the proportional valve, where I represents the proportional valve current, Indicates the target speed of the mixing bucket, represents the target engine speed, Indicates the dead zone current of the proportional valve, K is a constant. The controller adopts PID closed-loop control through PWM mode to realize high-precision output of proportional valve current.

[0021] Step 2. The controller outputs the throttle control voltage to the engine ECU, measures the actual engine speed through feedback, and adjusts the engine speed to the specified .

[0022] Step 3. The proportional valve controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com