Backflow preventing device

A technology of anti-backflow and valve body, which is applied in the direction of valve devices, control valves, functional valves, etc., can solve the problems of high manufacturing cost, complex structure, inconvenient installation and maintenance, etc., and achieve low manufacturing cost, small occupied space, Install covert effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

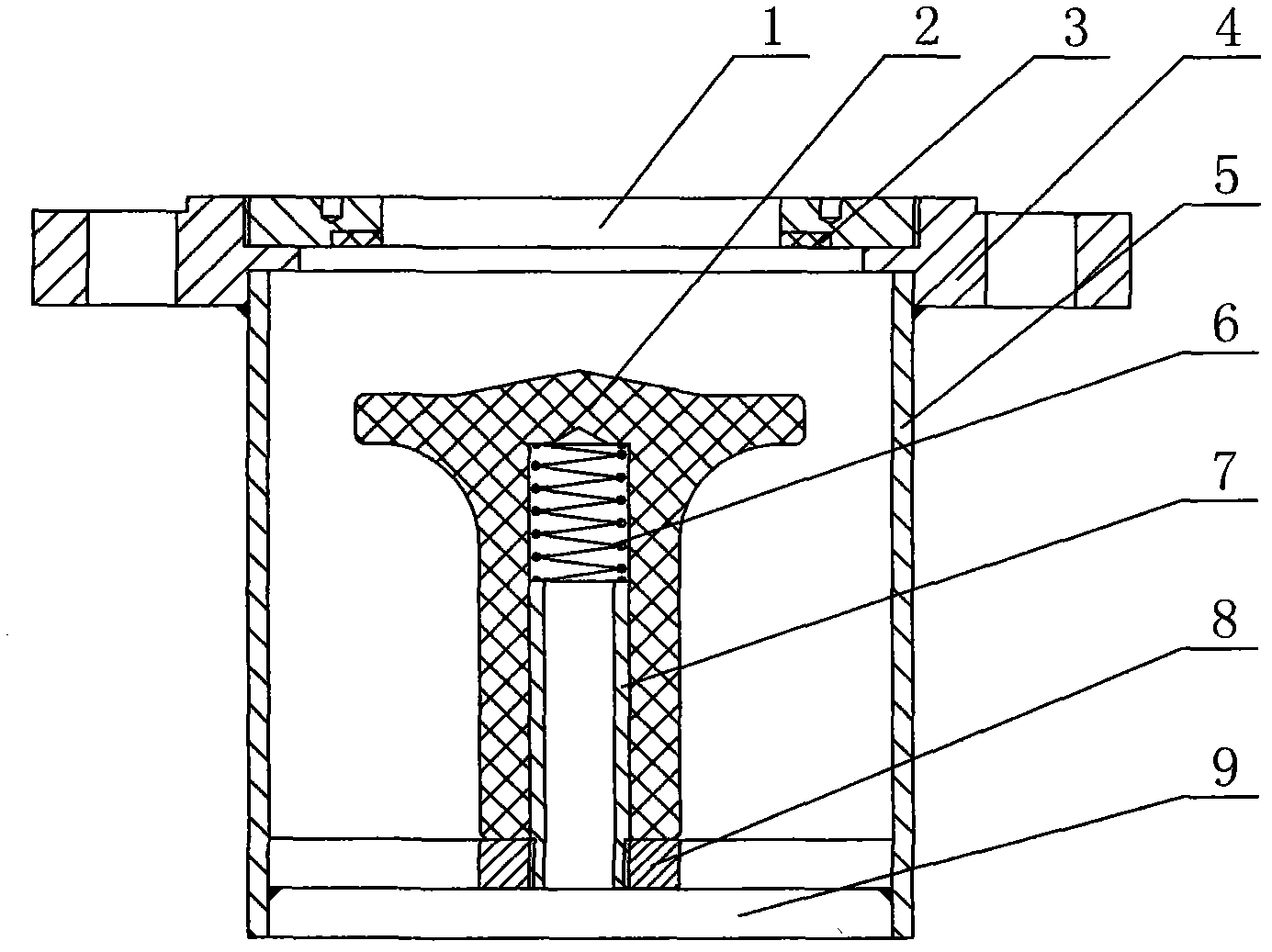

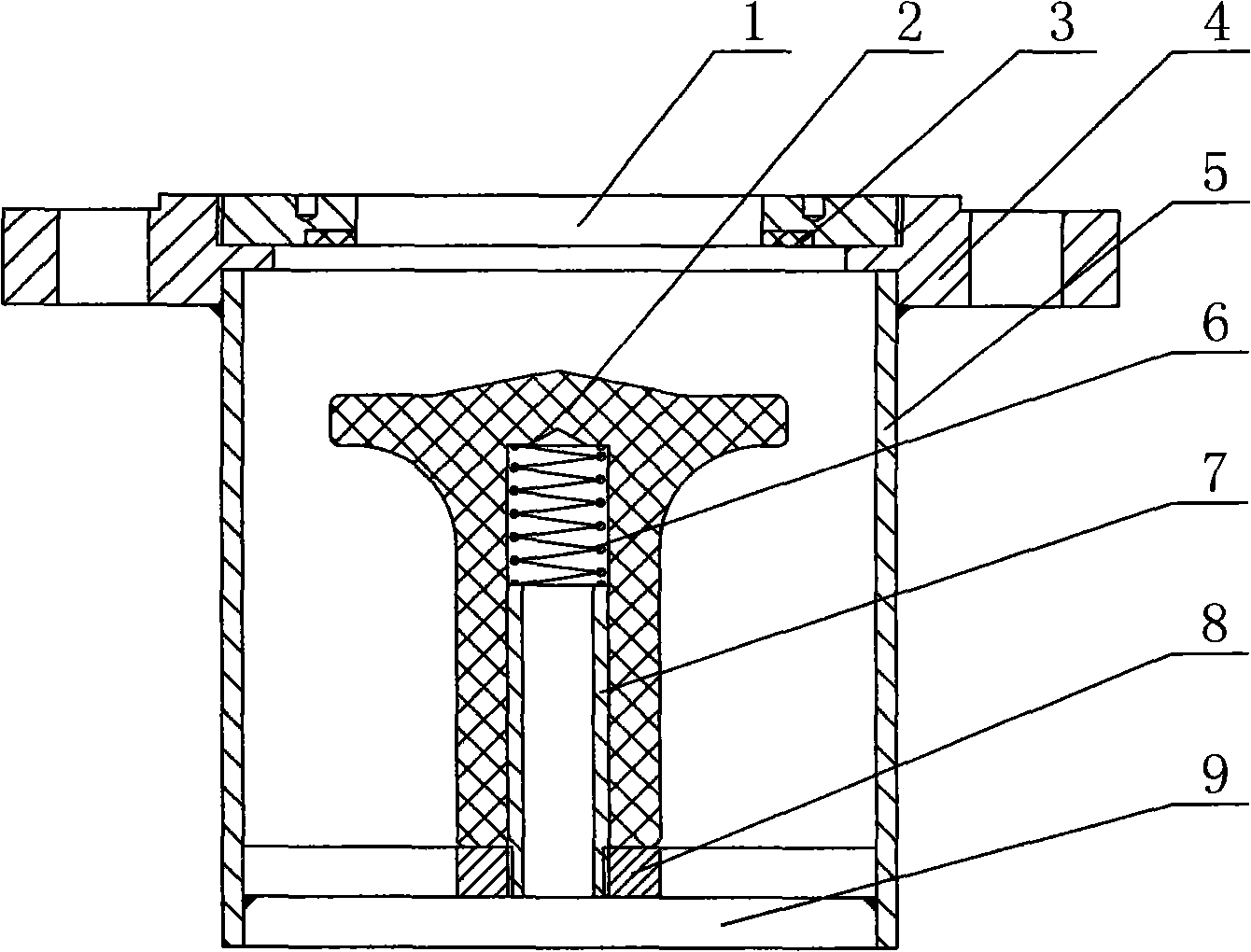

[0007] In the anti-backflow device shown in the accompanying drawings, the upper and lower ends of the valve body 5 are liquid inlet 1 and liquid outlet 9 respectively, and a bracket 8 is arranged inside the valve body 5, and a guide column 7 is arranged on the bracket 8, and a guide column 7 is installed on the guide column 7. The valve core 2 is slidingly arranged, and the guide column 7 guides and positions the valve core 2 with high precision. The spring 6 is arranged between the upper end of the guide column 7 and the valve core 2, and the valve body 5 on the lower side of the liquid inlet 1 corresponds to the valve core 2 A sealing gasket 3 is arranged on the top, and a flange 4 is arranged on the upper side of the valve body 5, which is easy to install and maintain.

[0008] When in use, the anti-backflow device is installed in the liquid pipeline or the inlet of the container. The installation is concealed and the space occupied is small. When the liquid enters from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com