Oil pump and equipment for non-connecting rod reciprocating-rotary motion conversion mechanism

A conversion mechanism and rotary motion technology, applied in the fields of compressors, internal combustion engines, and oil pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

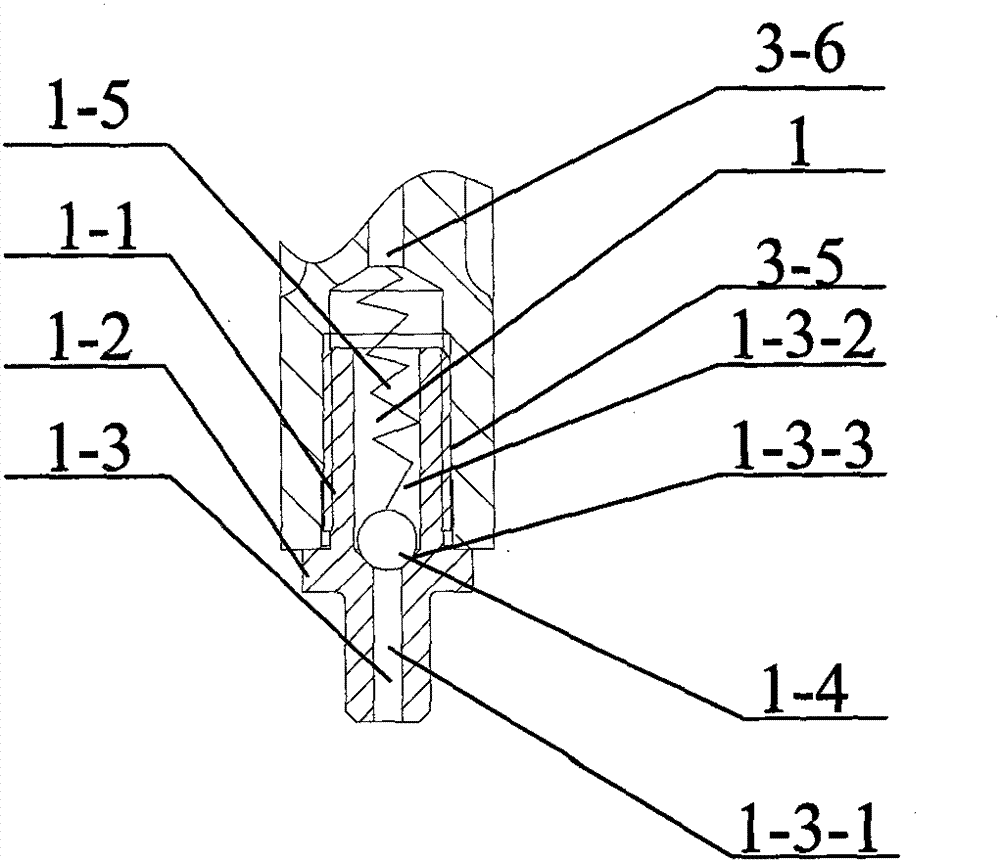

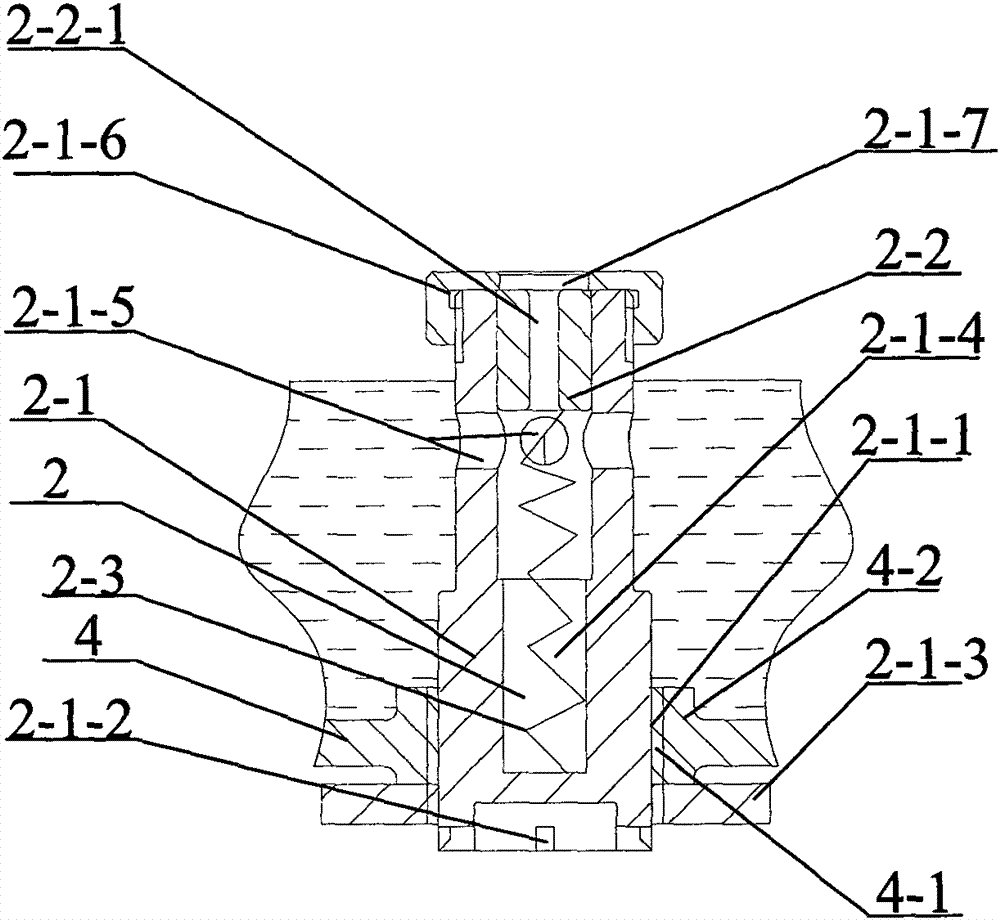

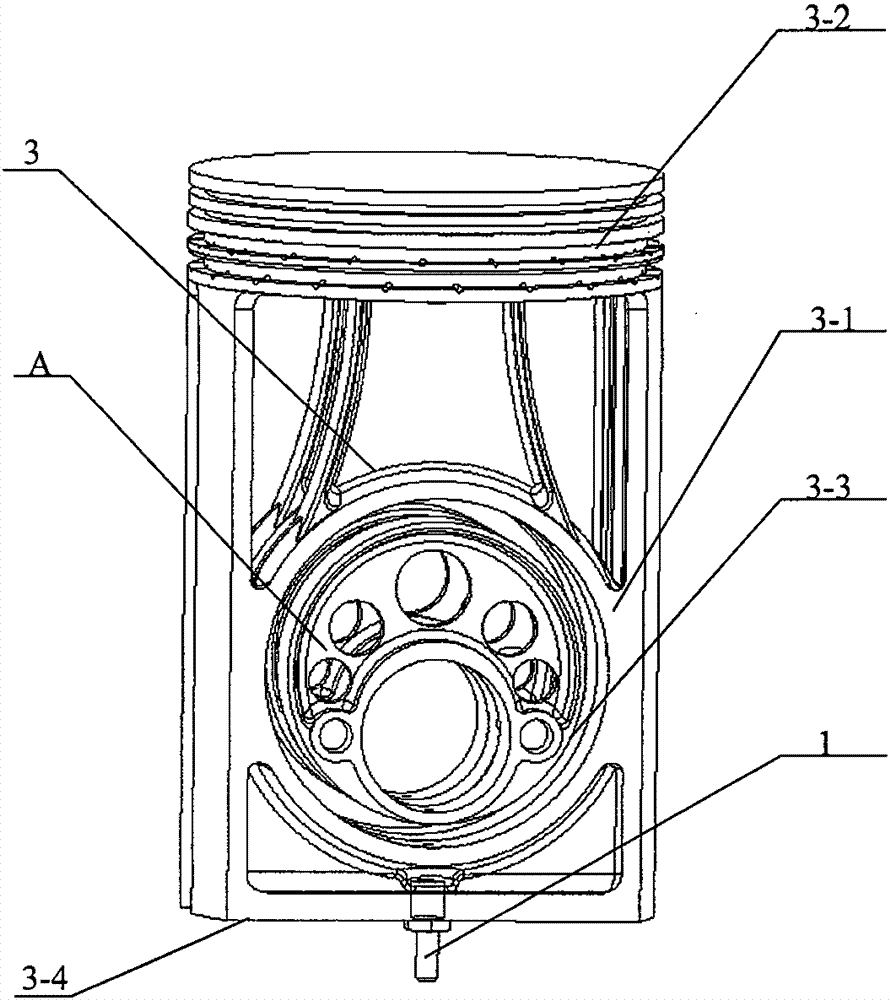

[0025] Please see figure 1 , which is a partial schematic diagram of the oil inlet joint 1 and the piston where it is used for an oil pump with a connecting rodless reciprocating-rotational conversion mechanism provided by the embodiment of the present invention. Please see also figure 2 , which shows the oil pump body 2 . In this embodiment, the linkless reciprocating-rotary motion conversion mechanism is used in an internal combustion engine. Please see also image 3 , which is a complete view of the single-acting piston with the oil inlet fitting installed. In this embodiment, the connecting-rod-free reciprocating-rotational conversion mechanism is specifically in the form of a cranked circular slider. As for the non-connecting rod reciprocating-rotary motion conversion mechanism in the form of an end shaft-moving shaft, as long as it has a single-acting piston, this technical solution is also applicable.

[0026] Such as image 3 As shown, the single-acting piston 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com