Light-emitting diode packaging structure

A technology of light-emitting diodes and packaging structures, which is applied in the direction of light sources, electric light sources, lighting devices, etc., and can solve problems such as changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below with reference to the accompanying drawings.

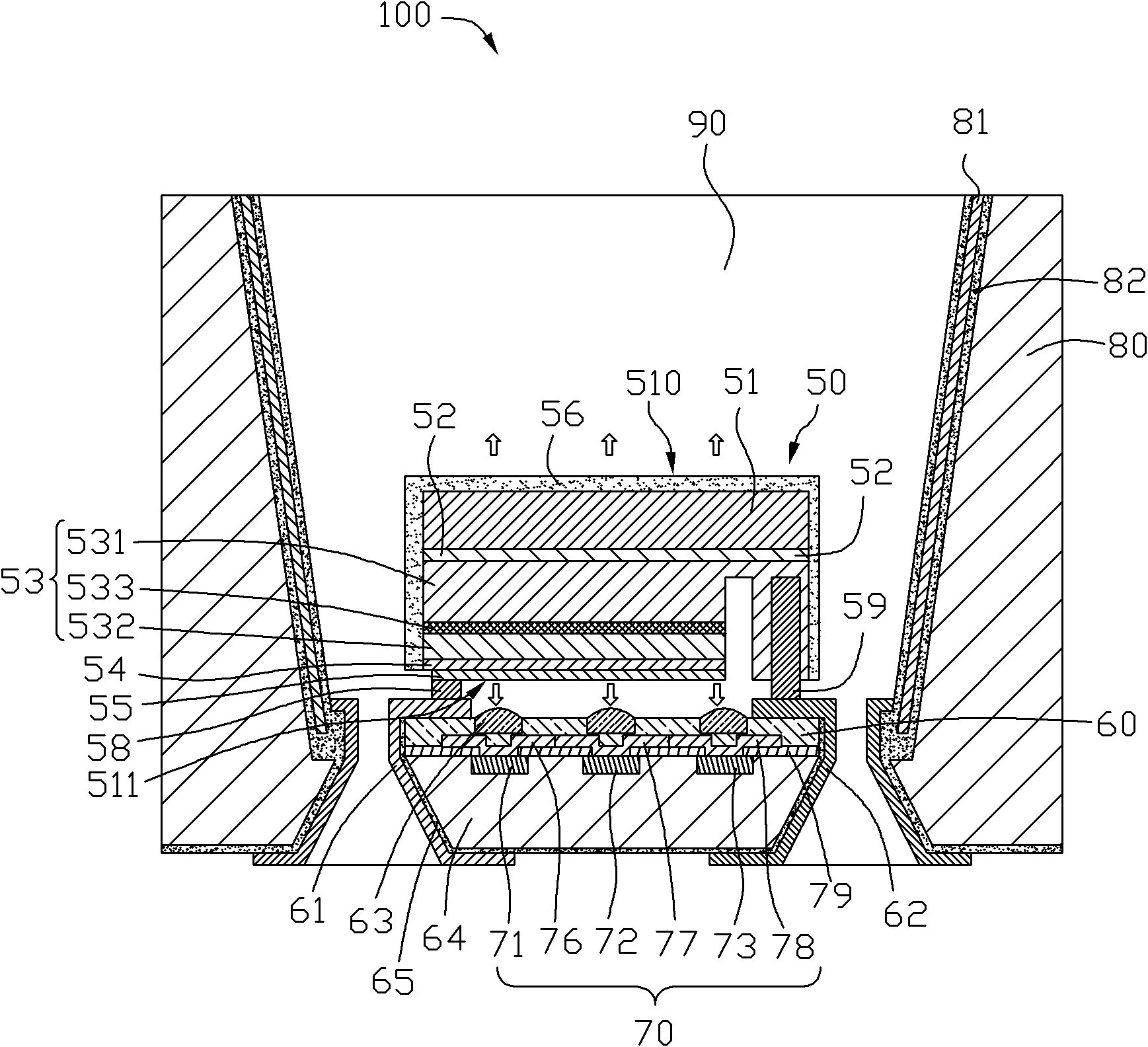

[0047] see figure 1 , which is a cross-sectional view of the light emitting diode package structure 100 according to the first embodiment of the present invention. The LED package structure 100 includes a LED chip 50 , a color sensing element 70 , a transparent insulating layer 60 connecting the LED chip 50 and the color sensing element 70 , a reflective cup 80 , and an encapsulant 90 . The light emitted by the light emitting diode chip 50 is detected by the color sensing element 70 through the transparent insulating layer 60 .

[0048] The light-emitting diode chip 50 is a flip-chip light-emitting diode chip in this embodiment. The light-emitting diode chip 50 includes a substrate 51 , a light-emitting structure 53 , a first electrode 58 , and a second electrode 59 . A buffer layer 52 is grown between the substrate 51 and the light emitting structure 53 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com