Laser light source

A laser light source and light source technology, applied in the field of laser light sources, can solve the problems of high design cost, color temperature fluctuation, complex structure, etc., and achieve the effects of simple manufacturing, stable color temperature, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

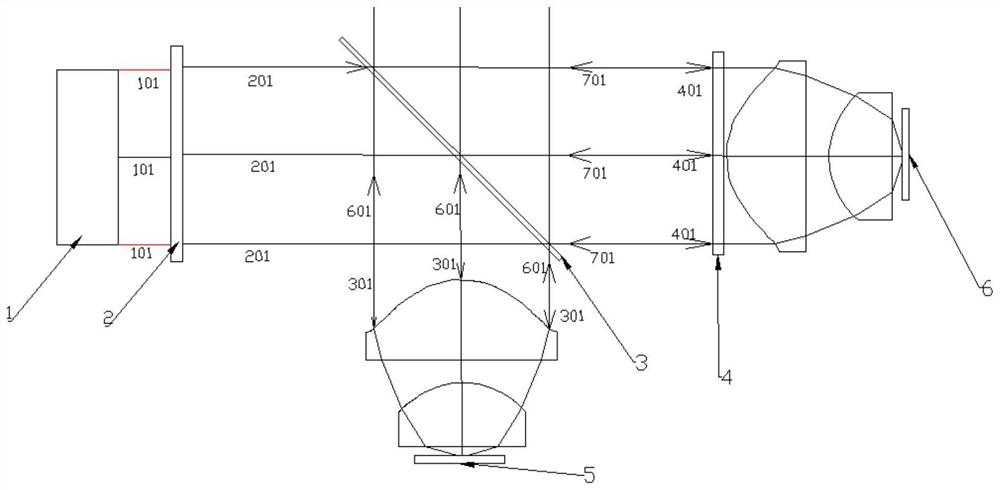

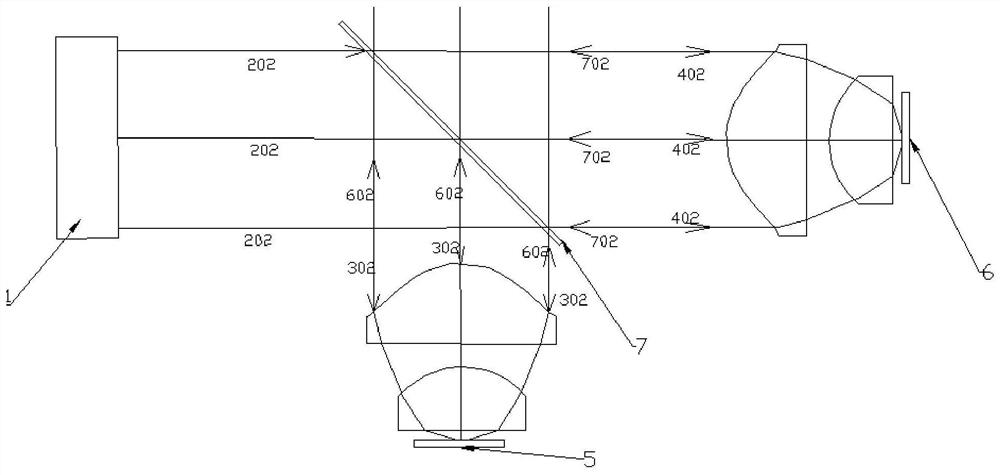

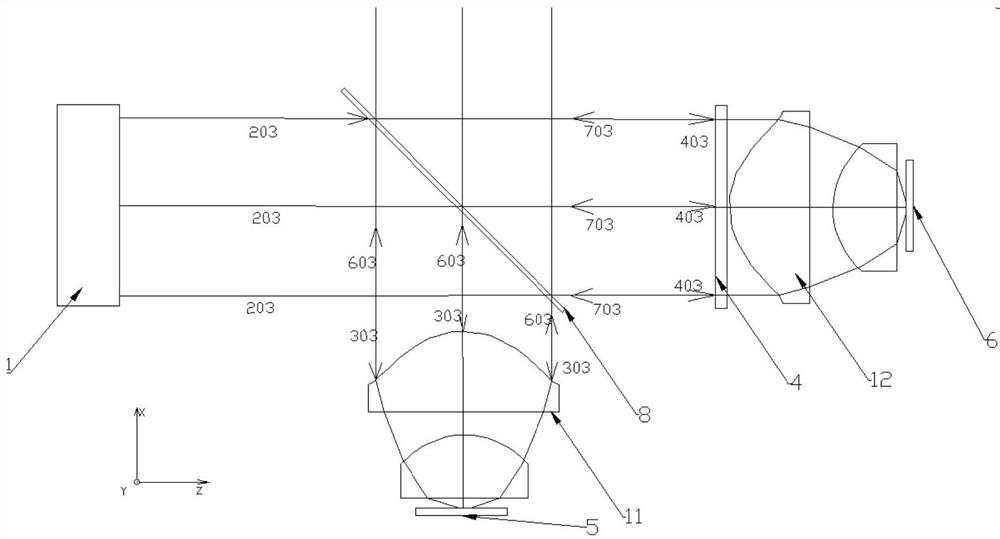

[0042] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0043] The invention relates to a laser light source, comprising: a blue laser light source assembly for generating parallel linearly polarized blue laser light, a dichroic polarizing beam splitter, a quarter wave plate, a reflection member and a wavelength converter; The color laser light source assembly is arranged on the XOY plane and emits the blue laser along the Z-axis direction, the dichromatic polarization beam splitter is arranged at an angle of 45 degrees to the XOY plane, and the blue laser light source assembly is arranged so that all The polarization direction of the blue lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com