Production device for double-layer crust steamed stuffed bun

A production equipment and double-layer leather technology, which is applied in food preparation, application, food science, etc., can solve problems such as outflow, buns that cannot be stored for a long time, and effects on the appearance and quality of buns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

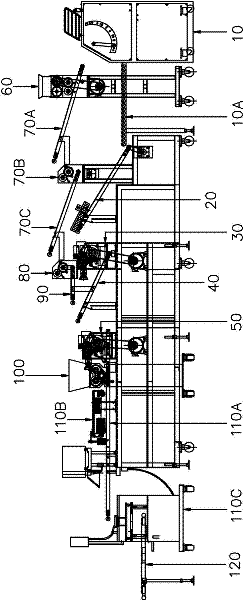

[0039] like figure 1 Shown, a kind of double-layer skin steamed stuffed bun production equipment, it comprises following parts:

[0040] The fermented dough production device is used to press the fermented dough, and the dough output end of the fermented dough production device is towards the input end of the steamed stuffed bun forming device;

[0041] Dough dough production device, for pressing the dough dough, the dough output end of the dough dough production device is towards the input end of the steamed bun forming device 50, and the dough output end of the dough dough production device is arranged on the dough of the dough dough production device the upper side of the output;

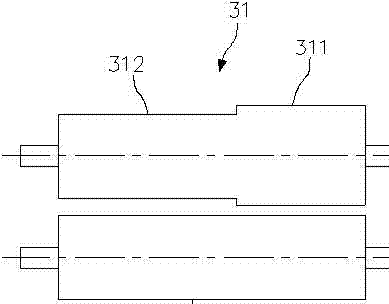

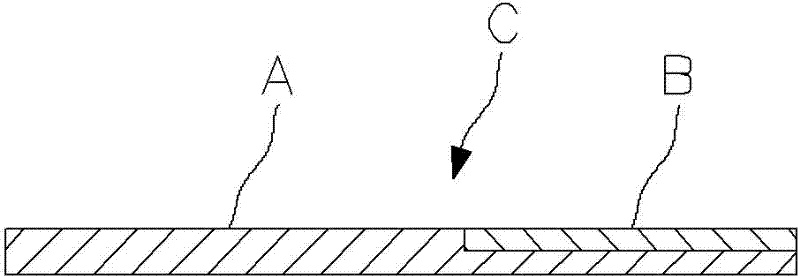

[0042] The steamed bun forming device 50 is used to superimpose and press the dried dough B output from the dry dough production device and the fermented dough A output from the fermented dough production device up and down to form a steamed bun skin C. The output end of the steamed bun skin for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com