Split type occipital plate

A split, occipital technology, applied in the directions of outer plate, inner bone synthesis, fixator, etc., can solve the problems of easy falling off of occipital plate, complicated operation process, difficult fixation, etc., to reduce the risk of slippage, convenient operation, Reduce the effect of strict requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

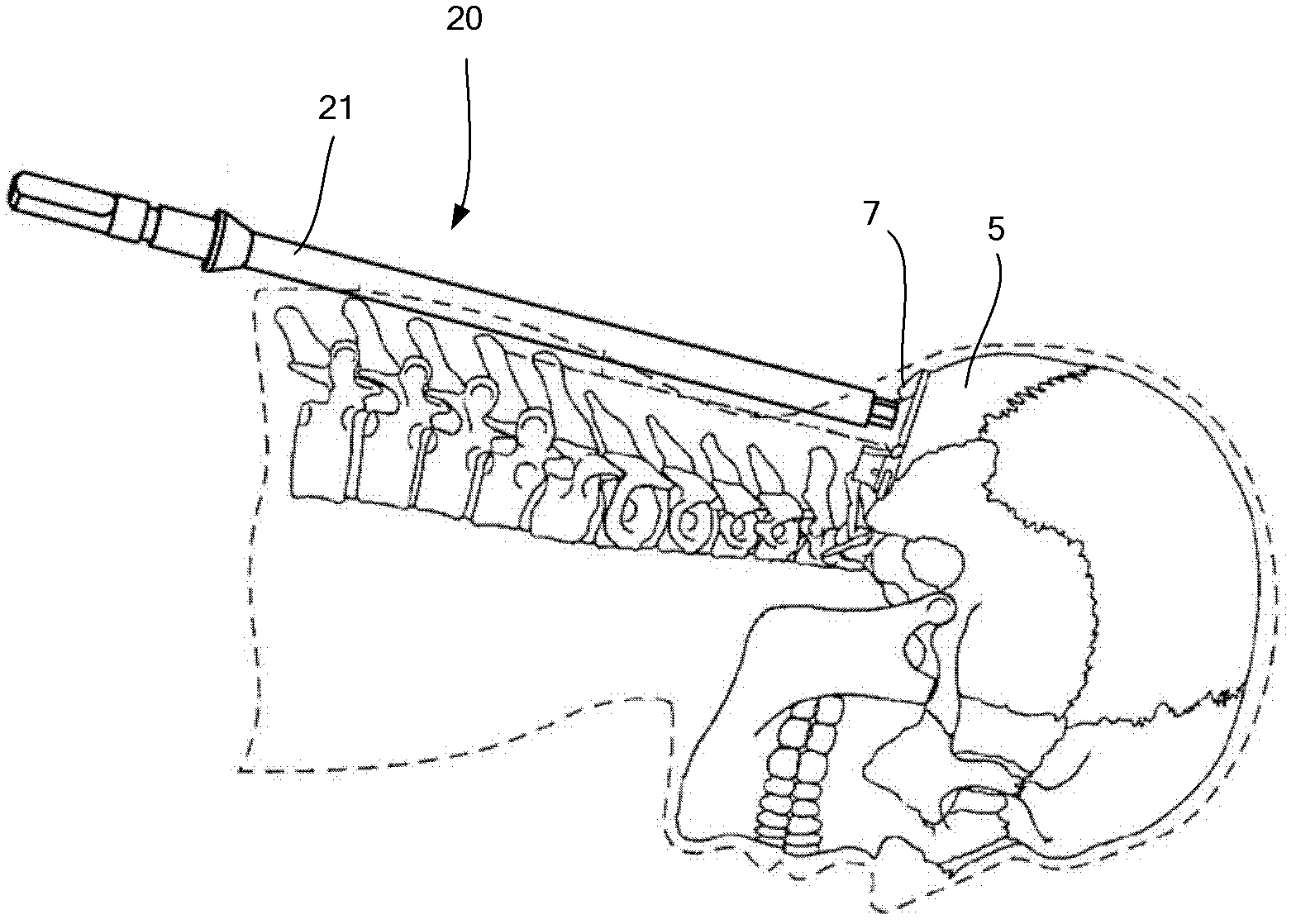

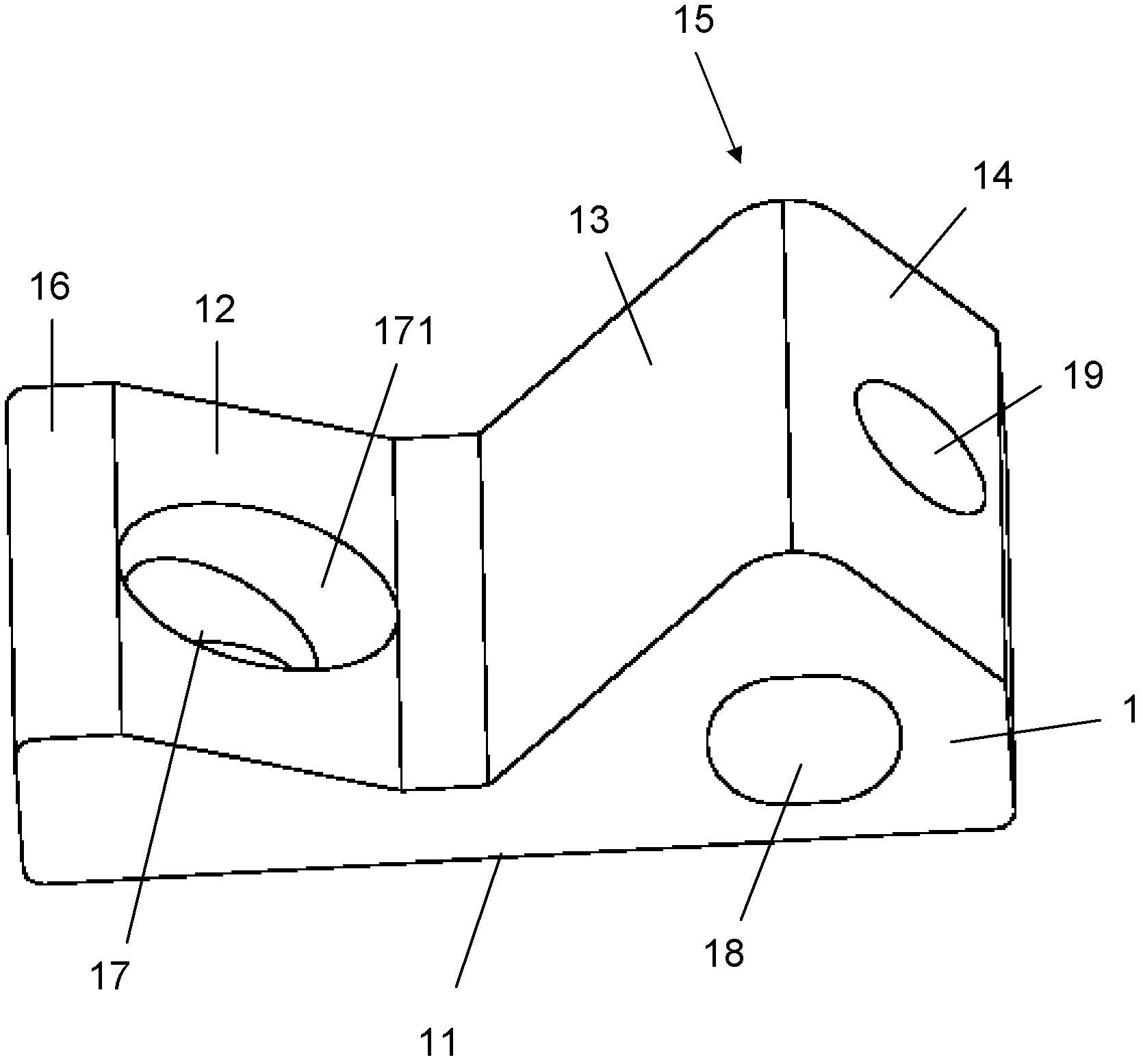

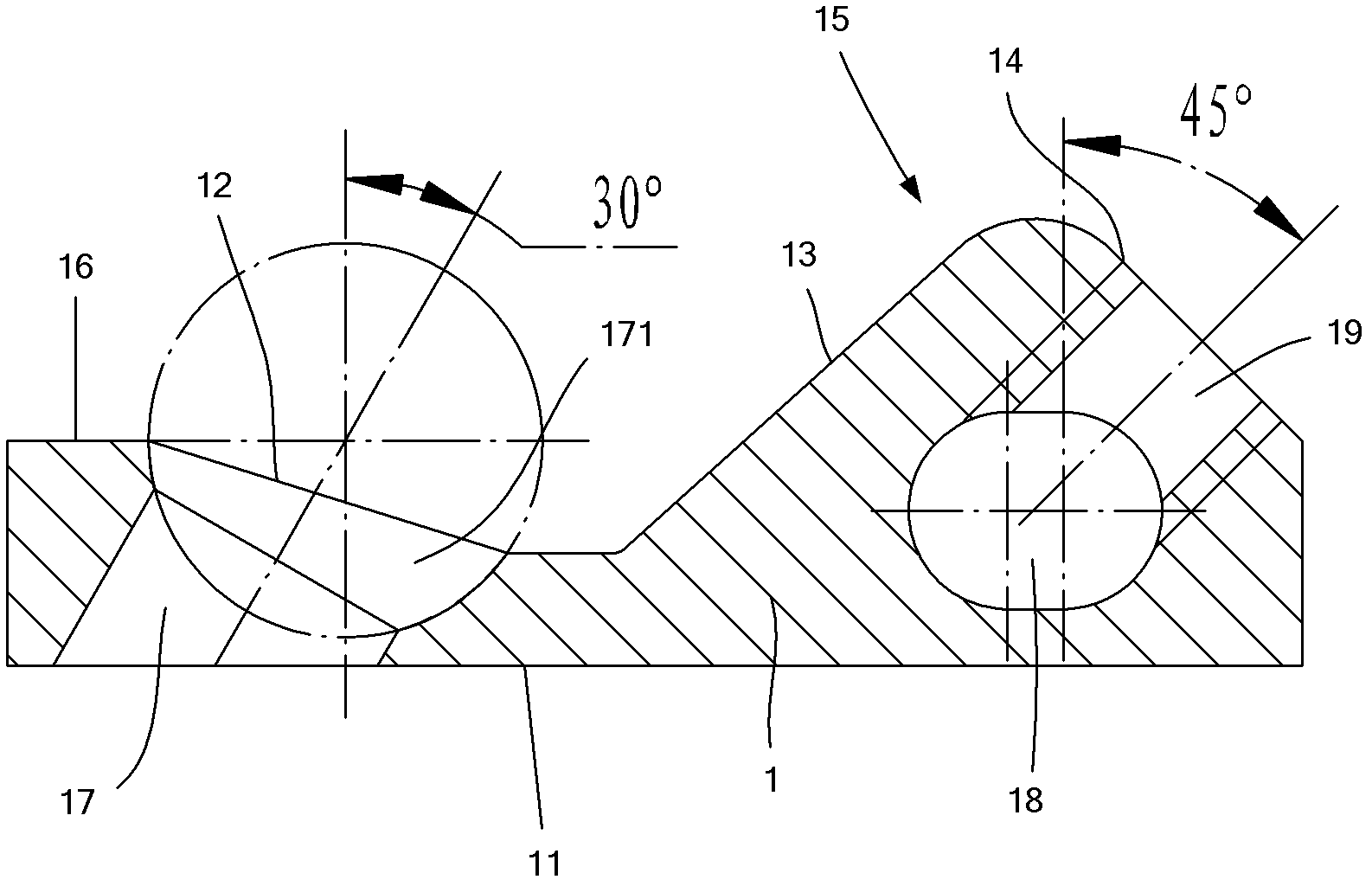

[0029] Such as figure 2 and image 3 As shown, the present invention includes a body 1, and the body 1 is made of titanium alloy or medical stainless steel. The lower end surface of the body 1 is the attachment surface 11 attached to the occipital bone 5 of the human body, which can be a plane, or an irregular surface composed of multiple planes or curved surfaces adapted to the anatomical structure of the human body, or a certain arc can be processed as required shape. The upper end surface of the body 1 can be a plane, or an irregular plane composed of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com