Flame cutting method of ultra-long single-sided rack

A single-sided rack and flame cutting technology, applied in the field of mechanical processing, can solve problems such as inability to apply single-sided rack cutting, unreliable fixing of cutting parts, and changes in physical and chemical properties of materials, so as to improve cutting processing efficiency, avoid deformation, The effect of high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The flame cutting method of the ultra-long single-sided rack provided by the present invention comprises the following steps A to D:

[0030] A. Preheat the whole steel plate to be cut to 200-300°C;

[0031] B. Fix the preheated steel plate on the cutting platform;

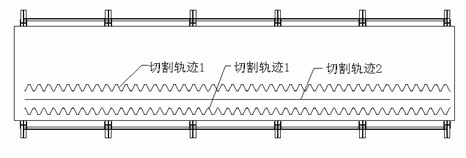

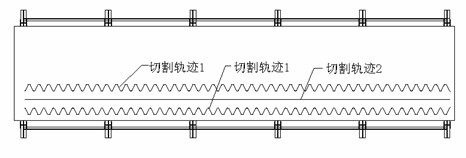

[0032] C. Measure the temperature of the steel plate, and start cutting when the temperature of the steel plate is between 100 and 150°C. During cutting, use two torches to cut two tooth edges along two cutting tracks 1 on the steel plate at the same time, and the distance between the two tooth edges is equal to a single The width of the rack plus the width of the kerf compensation, after the cutting is completed, a double-sided rack is obtained;

[0033] D. Cut the double-sided rack obtained in step C into two parts along the cutting track 2 to obtain two single-sided racks, and complete the rack cutting.

[0034] In step A, the overall preheating can be performed by placing the entire steel plate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com