Fixing support of mechanical jack of automobile and fixing method of jack

A fixed bracket and jack support technology, which is applied to vehicle parts, transportation and packaging, etc., can solve the problems of increased noise in the car, easy damage to the bottom plate, falling off, etc., and achieve the effect of reducing noise in the car, reducing damage, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

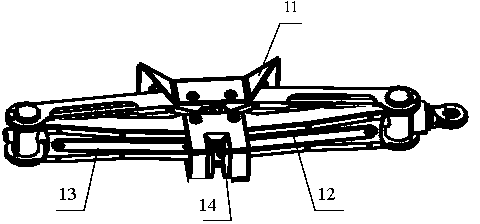

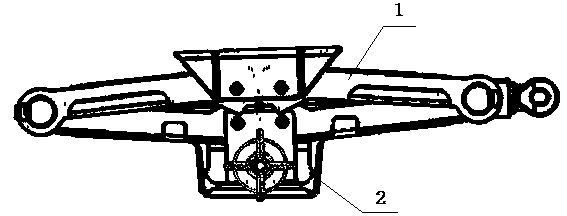

[0033] figure 1 A structural schematic diagram of an automobile mechanical jack is shown, the automobile mechanical jack is composed of a jack top surface 11 and a jack support frame, and the jack support frame is composed of a jack first support part 12 with a recess 14 and a jack second support part 13 .

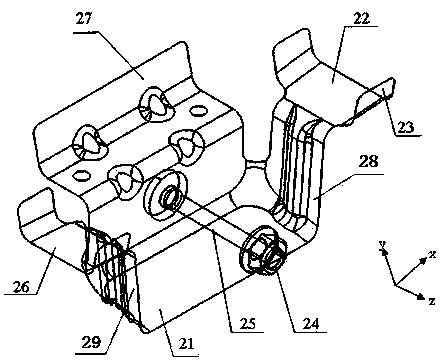

[0034] figure 2 It shows a schematic structural diagram of the mechanical jack fixing bracket of the present invention, including a brace 21, a first support body 28 and a second support body 29 symmetrically arranged at both ends of the brace 21, and the first support body support surface of the first support body 28 22 and the front and rear sides of the second supporting body supporting surface 26 of the second supporting body 29 are respectively symmetrically provided with limiting baffles 23 .

[0035] The first support body support surface 22 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com