Air feed and exhaust system for tunnel-type sterilizing dryer

A dryer and tunnel-type technology, applied in dryers, air-conditioning systems, packaging sterilization, etc., can solve problems such as easy backflow of unclean air into the oven tunnel, increase the burden on the indoor air-conditioning system, and affect the cooling effect of the cooling section. , to achieve the effects of easy and controllable pressure difference stability, maintain pressure difference and laminar flow stability, and ensure stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

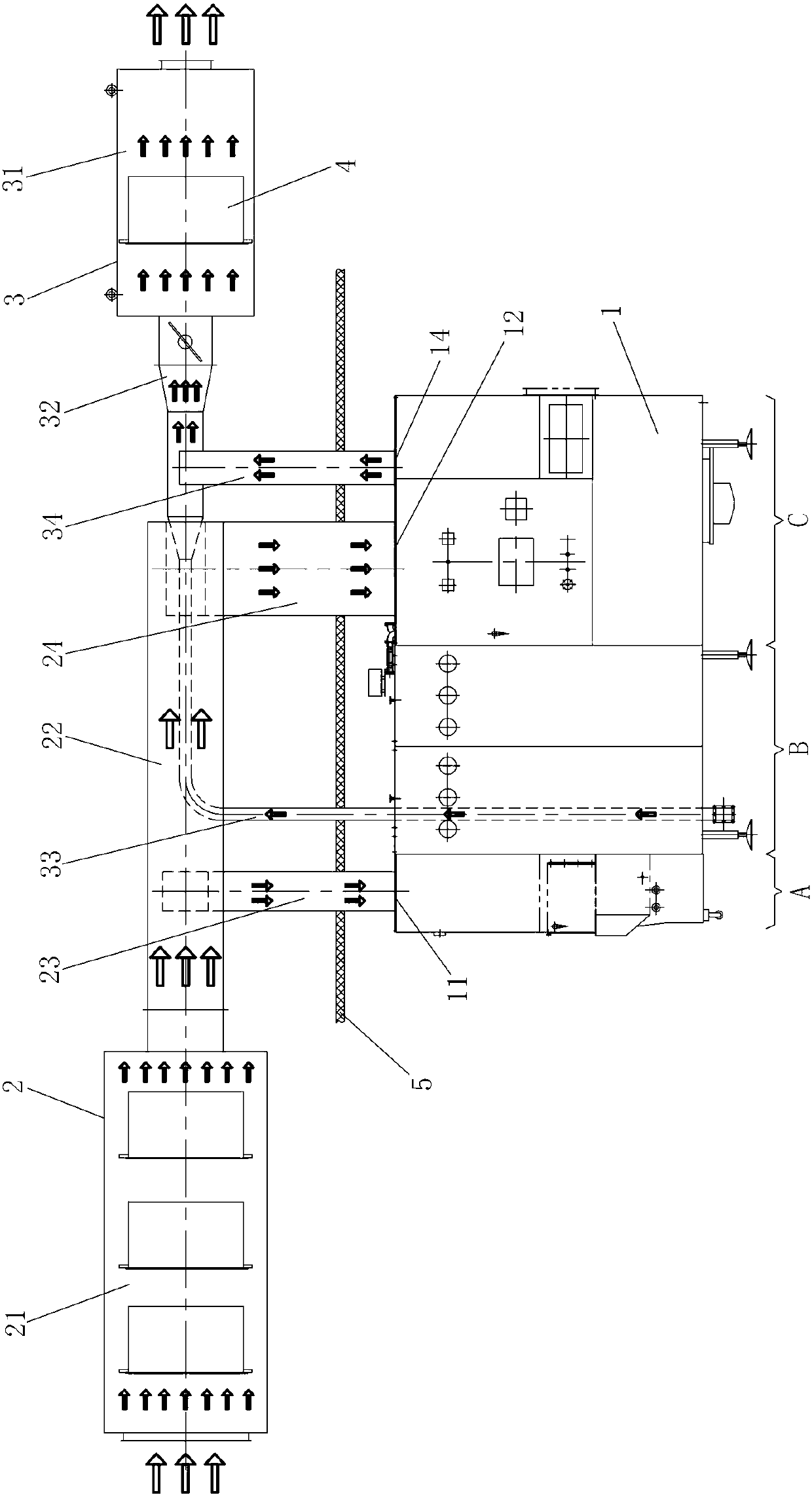

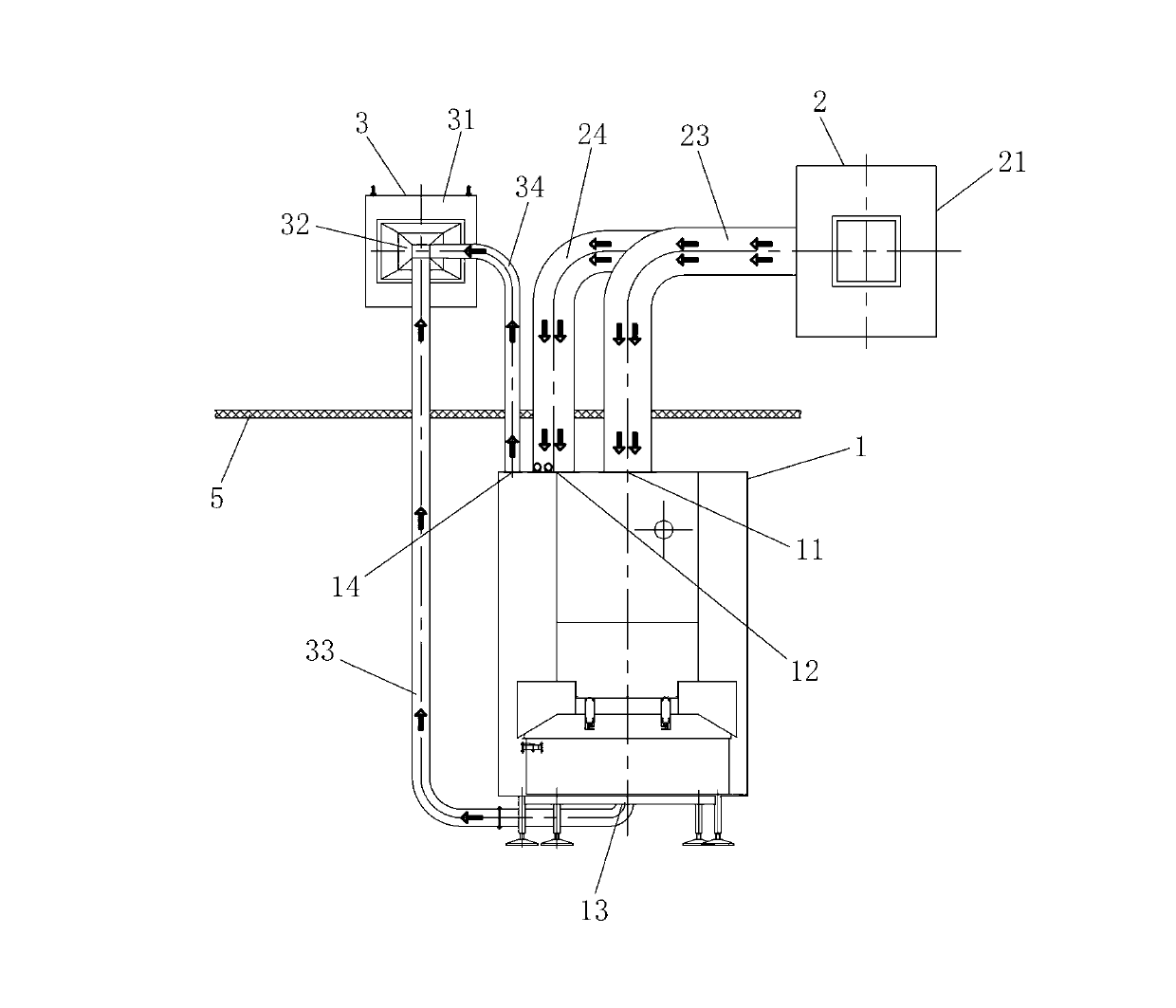

[0024] figure 1 and figure 2 An embodiment of the air supply and exhaust system of the tunnel type sterilization dryer of the present invention is shown, the air supply and exhaust system includes an oven assembly 1 located in the room, and a quantitative air supply assembly communicated with the oven assembly 1 2 and a quantitative exhaust assembly 3, the quantitative air supply assembly 2 can provide stable air supply for the oven assembly 1 and can adjust the air supply volume, and it can perform air supply according to actual needs, and the quantitative exhaust assembly 3 can be used for the oven assembly 1. Exhaust and adjust the exhaust air volume, and the air inlet of the quantitative air supply assembly 2 is located outdoors, the oven assembly 1 is the prior art, it is provided with a tunnel, and is divided into successively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com