Method for weaving three-dimensional crossed-pattern bag fabrics

A luggage fabric and cross technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of increasing printing and dyeing processes, not adapting to the needs of modern luggage consumers, increasing cost input, etc., to shorten the construction period and save processes cost, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

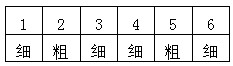

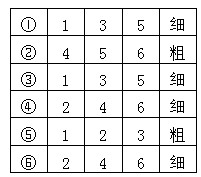

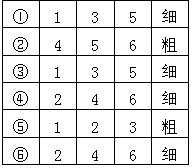

[0021] as attached figure 1 And attached figure 2 Shown, a kind of weaving method of three-dimensional cross wool bag fabric is processed by double warp beams and double jet looms, and adopts the following steps:

[0022] a. The warp adopts 800D yarn twisted 800T / m as the warp warp, and the machine pulls the warp on the nail warp to ensure that the process tension and the tension of each yarn are consistent, so that it can be used as a warp beam when it is off the machine; 150D black silk is used as the second warp Warp the 150D black silk as warp beams for use; after the two shafts are ready, thread them into the heald and reed them; p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com