Welding method to reduce stress and deformation of thick-walled steel structure on-site welding

A welding method and on-site welding technology, applied in the direction of welding/welding/cutting articles, welding equipment, welding equipment, etc., can solve the problems of structural stability, poor fatigue resistance, and cumbersomeness of difficult welded joints, and reduce fatigue crack growth The effect of reducing the speed, reducing the amount of structural deformation, and improving the stability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

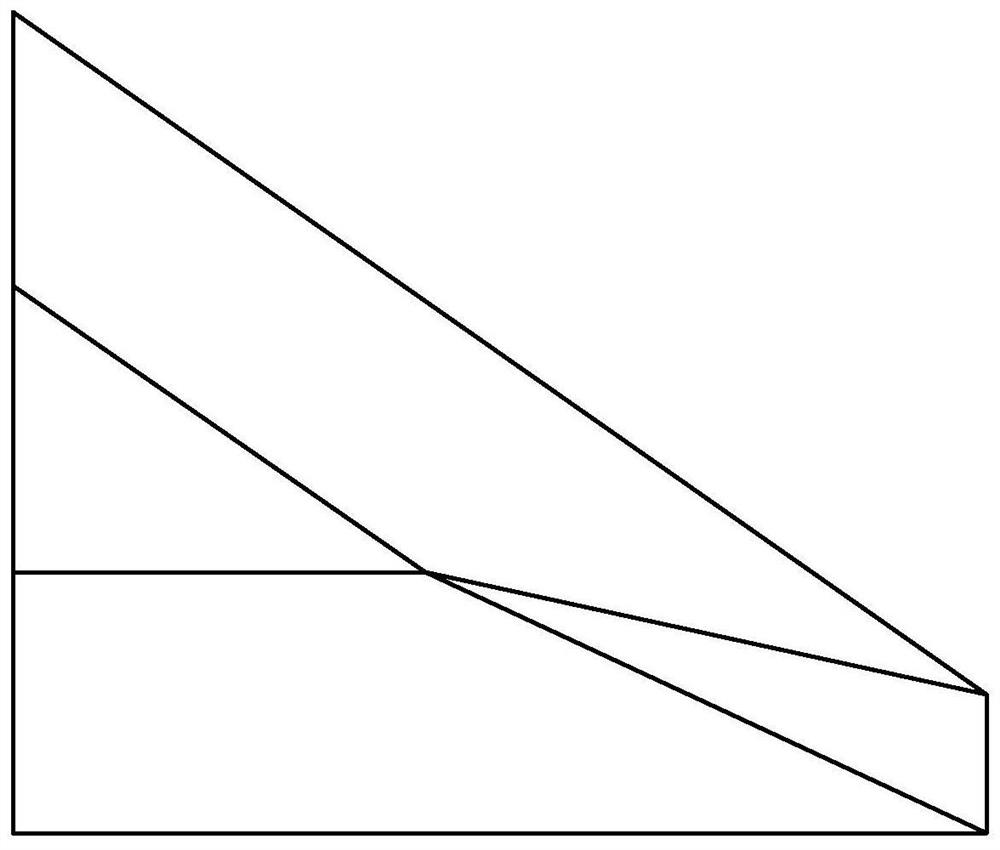

[0038] Specific implementation mode one: as Figure 1~6 As shown, the steps of the welding method for reducing the on-site welding stress and deformation of thick-walled steel structures in this embodiment are as follows:

[0039] Step 1. The material of the built-in web is selected to be the same as that of the base metal of the thick-walled steel structure; the plane geometry and outline size of the built-in web are set to be the same as the cross-section of the welding groove;

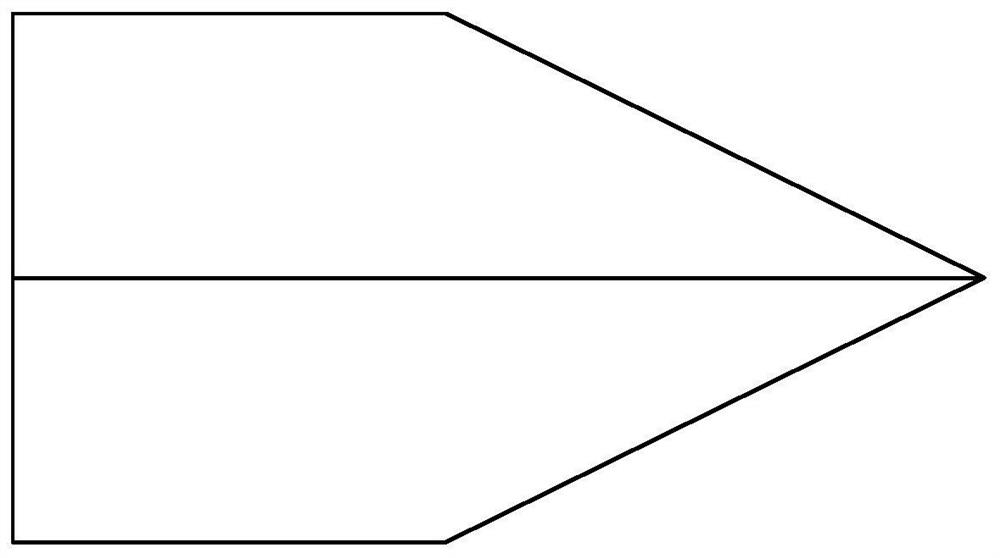

[0040] Step 2: At the welding groove of the butt joint, a number of inlaid built-in webs are arranged at intervals along the length direction of the weld, and the "skeleton system structure" is composed of the welding groove wall of the base metal and several inlaid built-in webs ;

[0041] Step 3. For the weld bevel of circular pipe butt joints: arrange the minimum distance between two adjacent built-in webs to be 314mm; for the weld bevel of non-circular pipe butt joints, arrange the minimum dist...

specific Embodiment approach 2

[0045] Embodiment 2: The welding method in step 5 of this embodiment is symmetrical welding, layered welding or segmented welding. In this way, on the basis of the support function of the skeleton formed by the built-in web, the welding stress and the equalization of structural deformation can be better controlled, and the longitudinal welding stress of the weld metal can be reduced as much as possible. Other operation steps are the same as those in the first embodiment.

specific Embodiment approach 3

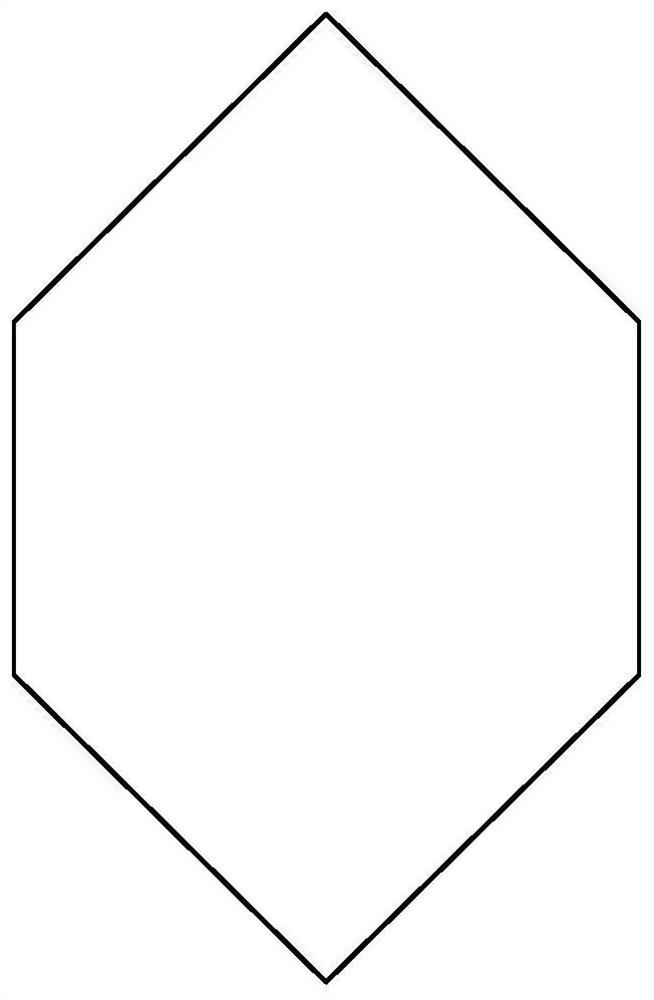

[0046] Specific implementation mode three: as Figure 1~3 As shown, the profile of the built-in web inlaid in this embodiment is wedge-shaped. According to the specific geometric shape of the welding groove section, the projection of the thickness direction of the built-in web is generally a trapezoid, an equilateral triangle, a scalene triangle or a scalene quadrilateral, etc. Such a design can make the plane geometric shape and size of the built-in web the same as the cross-section of the welding groove, which facilitates the seamless inlay of the built-in web in the welding groove and strengthens the "supporting effect" of the built-in skeleton. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com