Lightweight steel construction roof

A light steel structure and construction technology, applied in the direction of buildings, roofs, building components, etc., can solve the problems of delayed construction period, easy damage, long construction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

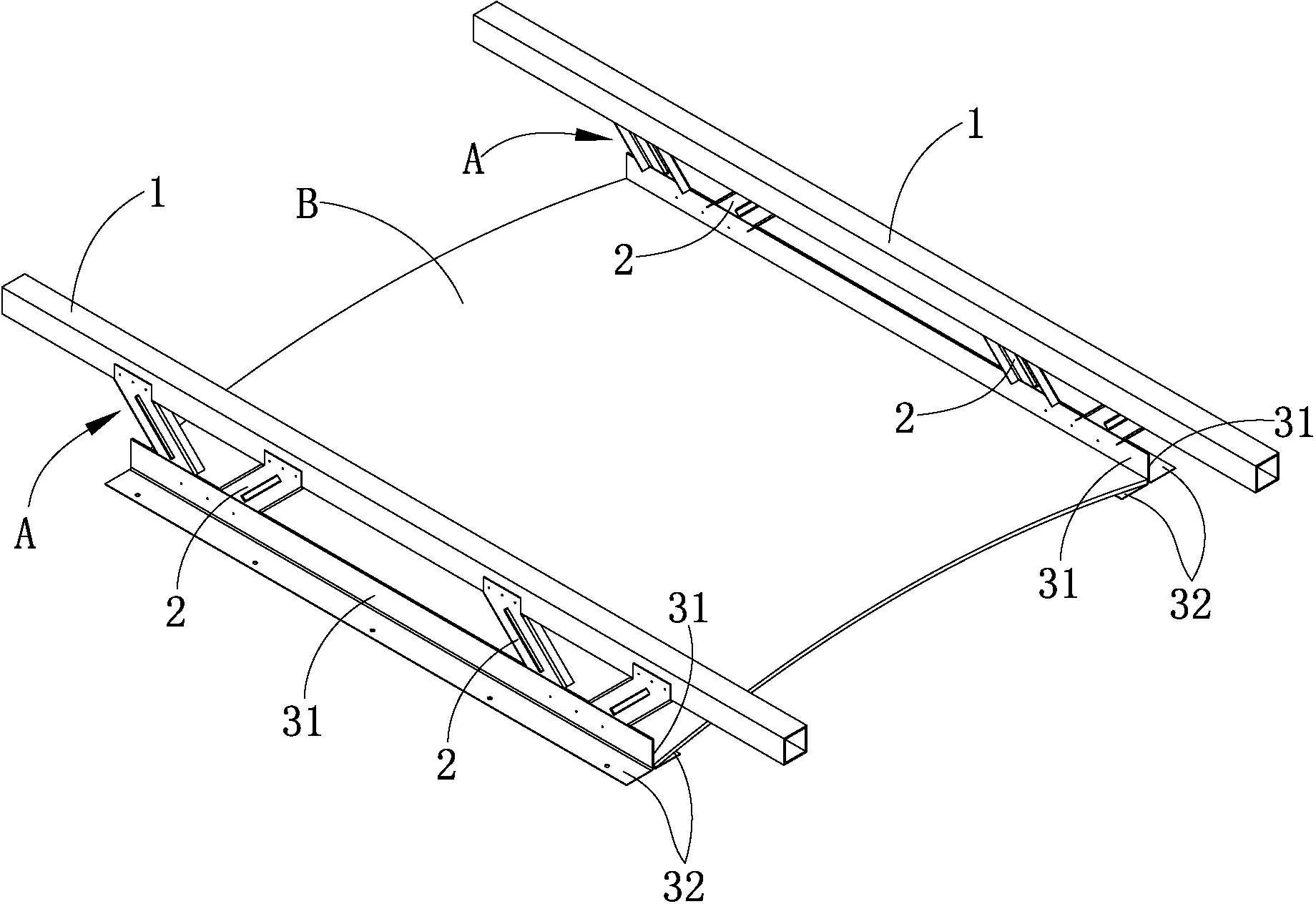

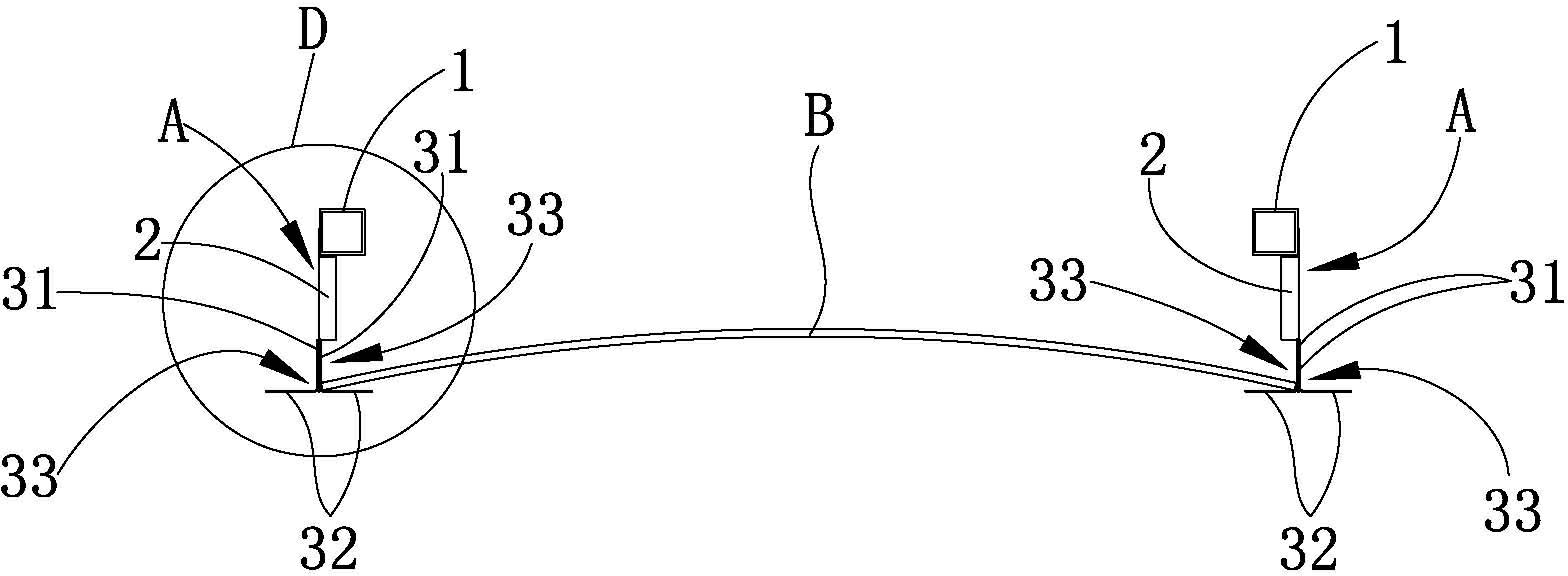

[0033] see figure 1 — Figure 4 :

[0034] The roof consists of several vertical trusses A parallel to each other, an arched plate B connected between the lower ends of every two adjacent trusses A, containing every two adjacent trusses A and the arched plate B between them The covering layer C.

[0035] For the sake of succinct explanation, figure 1 , figure 2 , image 3 Only two vertical trusses A and one arched plate B are shown in . The two trusses A can be of corresponding length according to design requirements, and then overlapped on the walls or structural beams on both sides of the house (the walls or structural beams are not shown in the drawings).

[0036] Each truss A includes a horizontal upper tube 1, two vertical V-shaped connectors 2, two horizontal L-shaped lower angle steels symmetrically located below the upper tube 1 and parallel to the upper tube 1;

[0037] The two vertical wing plates 31 of the two lower angle steels are spaced in parallel, and t...

Embodiment 2

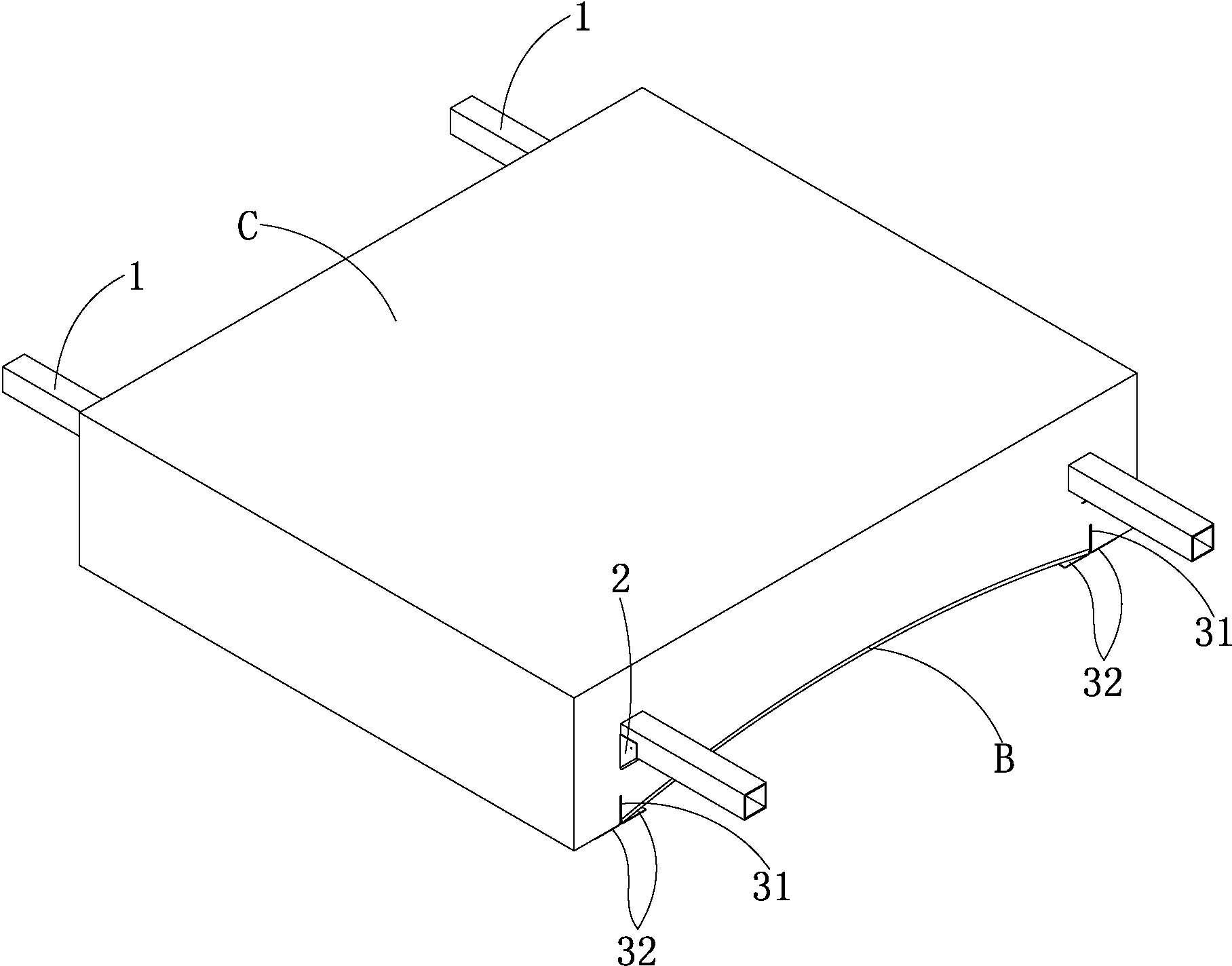

[0045] see Figure 5 — Figure 8 :

[0046] The roof consists of several vertical trusses A parallel to each other, an arched plate B connected between the lower ends of every two adjacent trusses A, containing every two adjacent trusses A and the arched plate B between them The covering layer C.

[0047] For the sake of succinct explanation, Figure 5 , Figure 6 , Figure 7 Only two vertical trusses A and one arched plate B are shown in . The two trusses A can be of corresponding length according to design requirements, and then overlapped on the walls or structural beams on both sides of the house (the walls or structural beams are not shown in the drawings).

[0048] Each truss A includes a horizontal upper pipe 1, several vertical V-shaped connectors 2, a downward extending horizontal sword-shaped angle steel below the upper pipe 1 and parallel to the upper pipe 1;

[0049] The two inclined wing plates 32 of the sword-shaped angle steel extend outward and are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com