High-energy consumption viscoelastic vibration isolating damper for engine

A high-energy-consumption viscoelasticity, engine technology, applied in the direction of solid shock absorbers, can solve the problems of no vibration isolation effect, and the vibration control effect is not very good, and achieves enhanced vibration isolation effect, simple structure, and increased service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

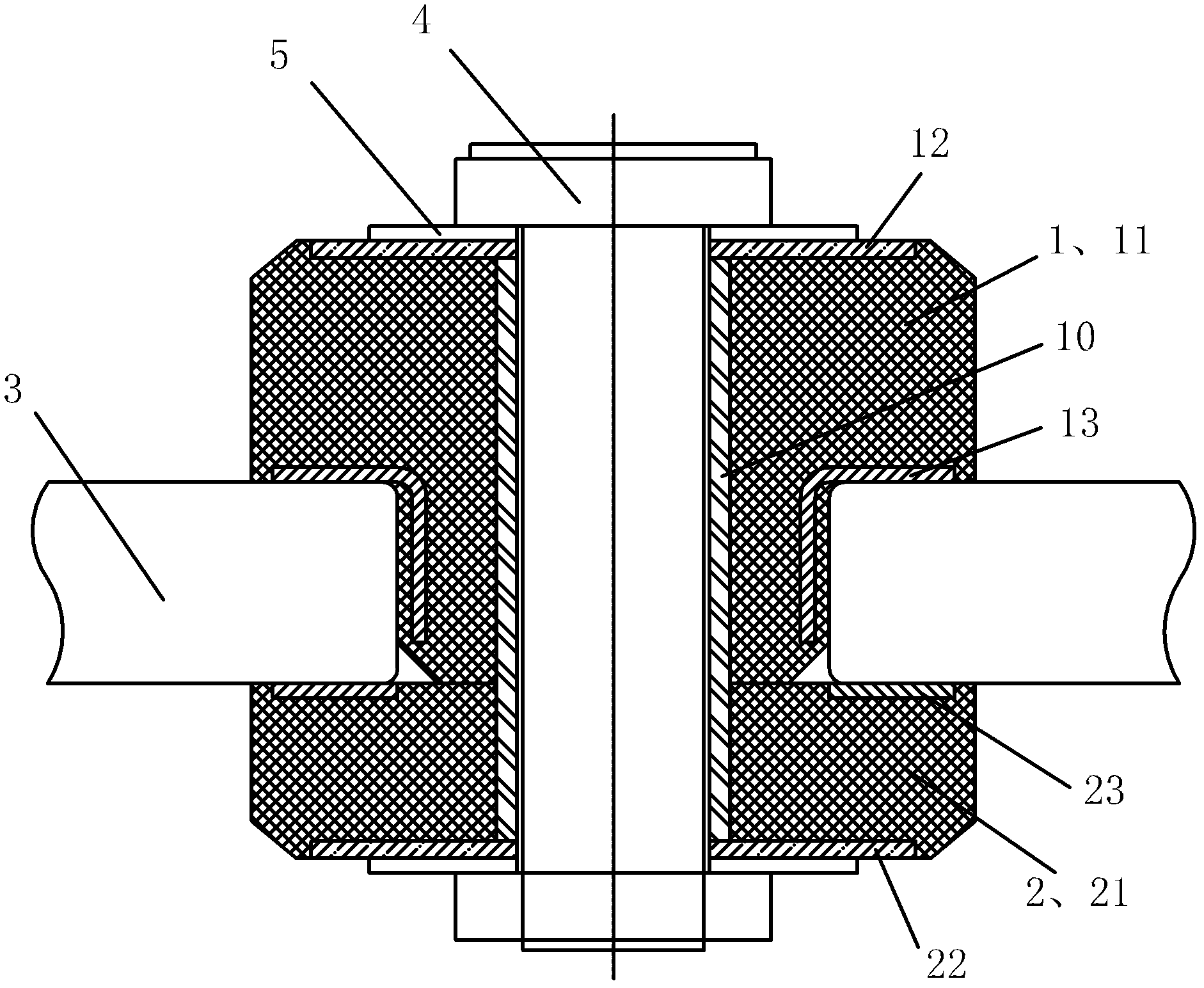

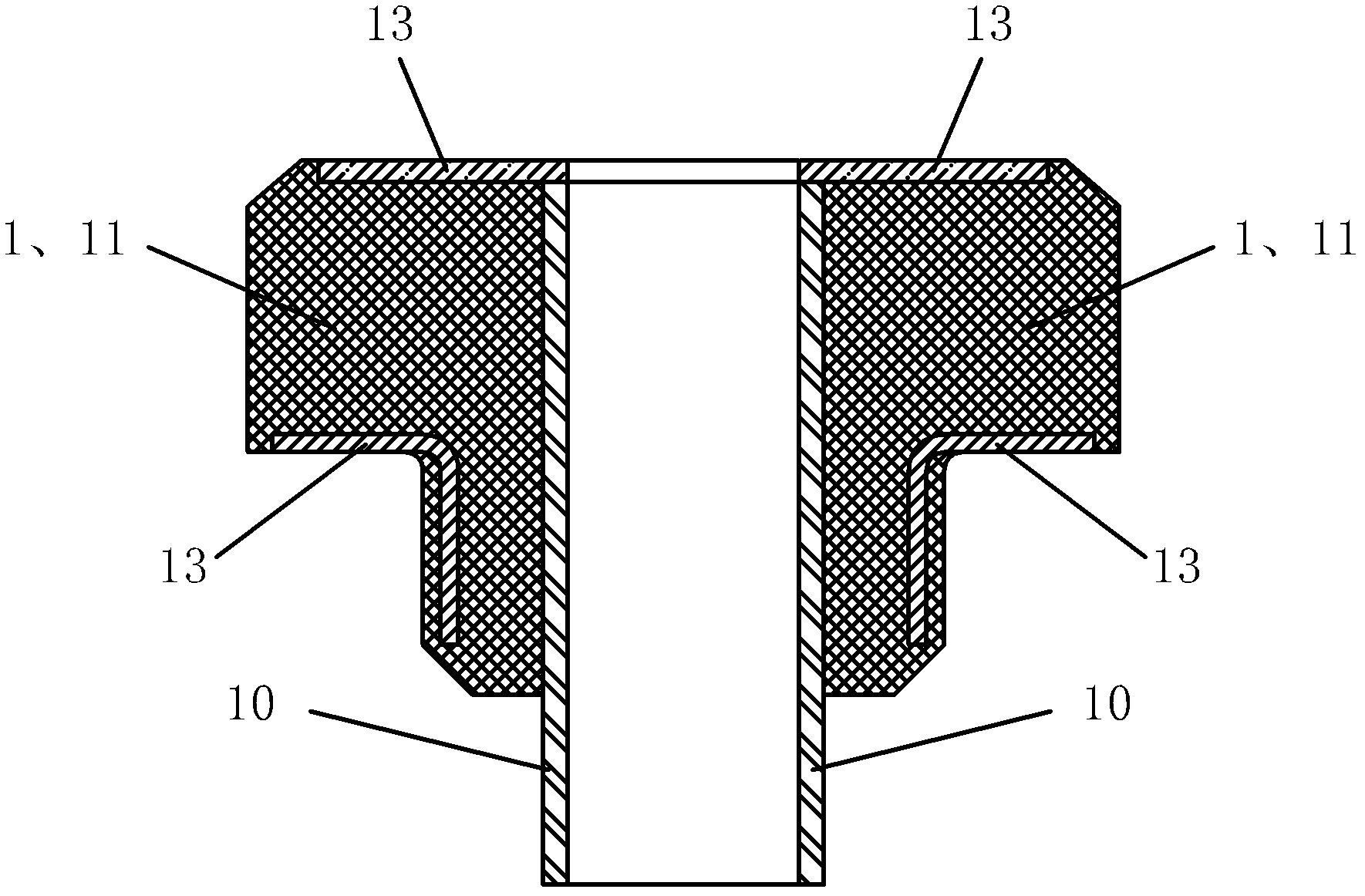

[0013] See Figure 1 to Figure 3 , The high energy consumption viscoelastic shock absorber for the engine of this embodiment includes an upper shock absorber 1 and a lower shock absorber 2 .

[0014] The upper shock absorbing block 1 includes a central shaft 10, a high energy consumption viscoelastic material 11 fixed on the central shaft 10, an upper metal washer 12 arranged on the top surface of the high energy consumption viscoelastic material 11 and an upper metal washer 12 arranged on the high energy consumption viscoelastic material 11. The upper bracket 13 at the bottom of the material 11.

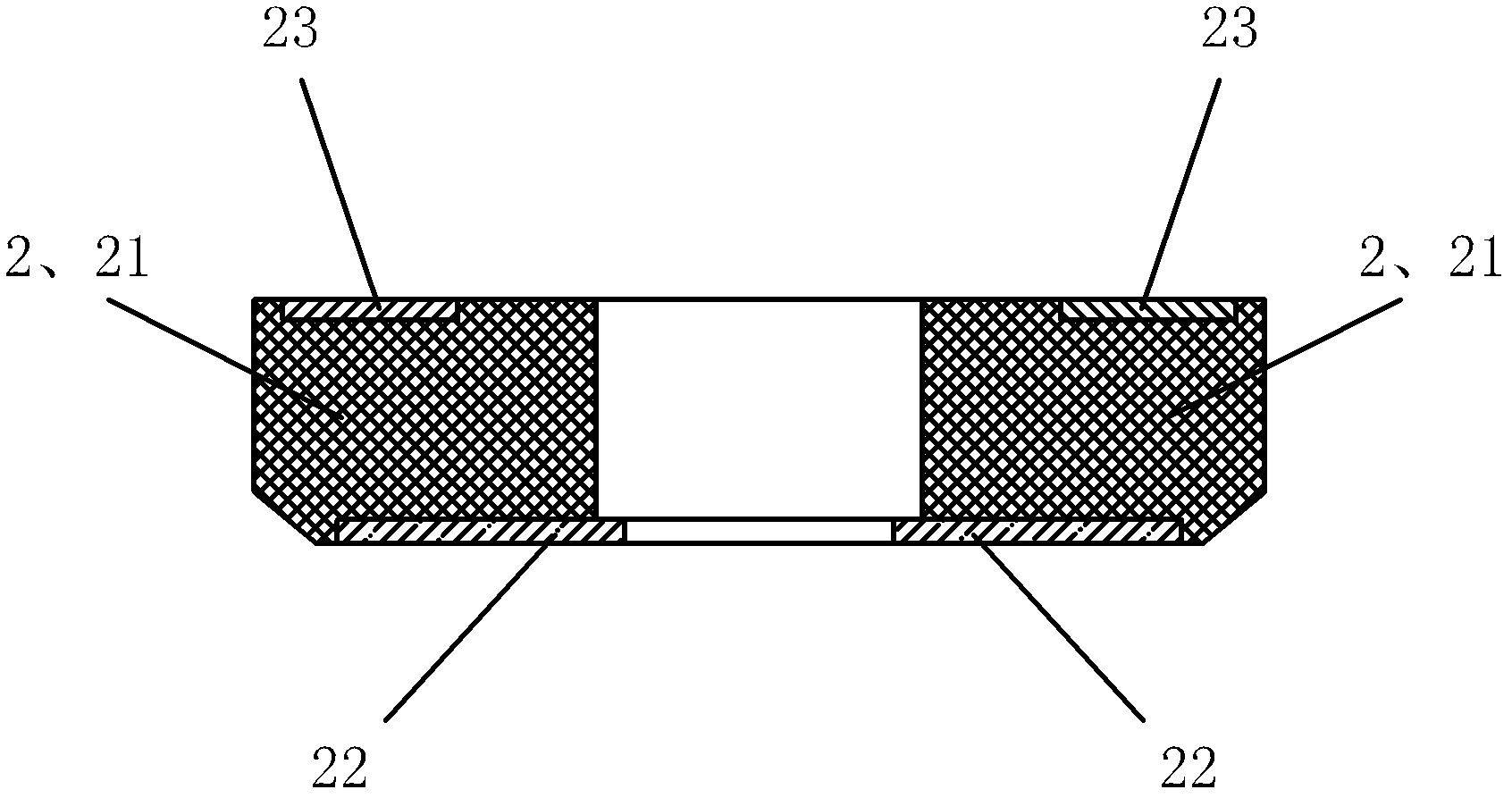

[0015] The lower shock-absorbing block 2 includes a high-energy-dissipating viscoelastic material 21 , a lower metal washer 22 arranged on the bottom surface of the high-energy-dissipating viscoelastic material 21 , and a lower bracket 23 arranged on the upper part of the high-energy-dissipating viscoelastic material 21 .

[0016] The shock absorber of this embodiment is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com