Multifunctional combined test valve for gas moisture and decomposer tests of transformer substation

A multi-functional combination and decomposition technology, applied in the direction of functional valve types, control valves, valve devices, etc., can solve problems such as inability to interchange joints, unsafe power grids, air pollution, etc., to achieve good promotion value, avoid equipment accidents, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

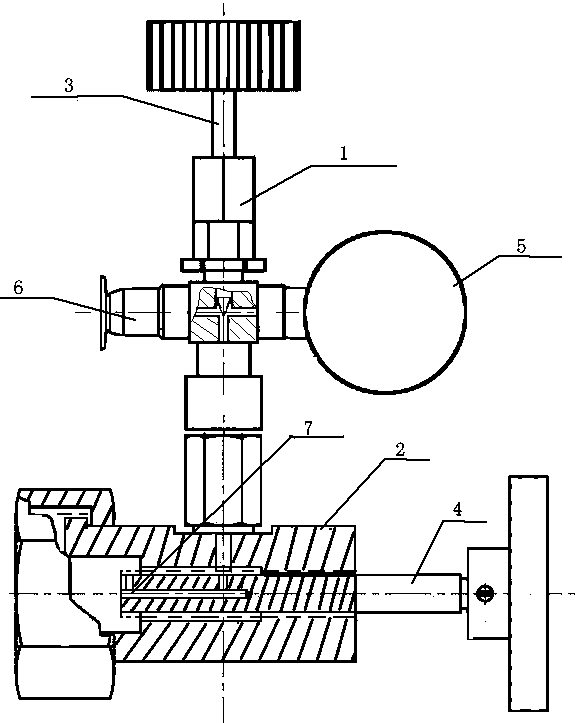

[0014] as attached figure 1 The multifunctional combination test valve of the embodiment of the present invention shown includes a three-way needle valve 1 and an angle valve 2 assembled together: the two valve interfaces of the angle valve 2 are at right angles, and the valve stem 4 of the angle valve is columnar. The valve stem 4 of the angle valve is provided with a ventilation slot 7 corresponding to the valve interface perpendicular to the valve stem 4; the valve interface perpendicular to the valve stem 4 on the angle valve 2 is fitted on the needle valve 1 and faces the needle valve stem 3 on the valve interface. When in use, a pressure gauge 5 and a quick connector 6 need to be connected to the other two valve ports of the needle valve 1 respectively.

[0015] When the present invention is in use, a pressure gauge and a quick connector need to be respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com