Separation mechanism of oriented rocket nose body

A separation mechanism and guided technology, applied in the direction of projectiles, self-propelled missiles, offensive equipment, etc., can solve the problems of low reliability, inability to guarantee the attitude of the separation part, and difficulty in ensuring synchronization, and achieve good reliability and simple structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

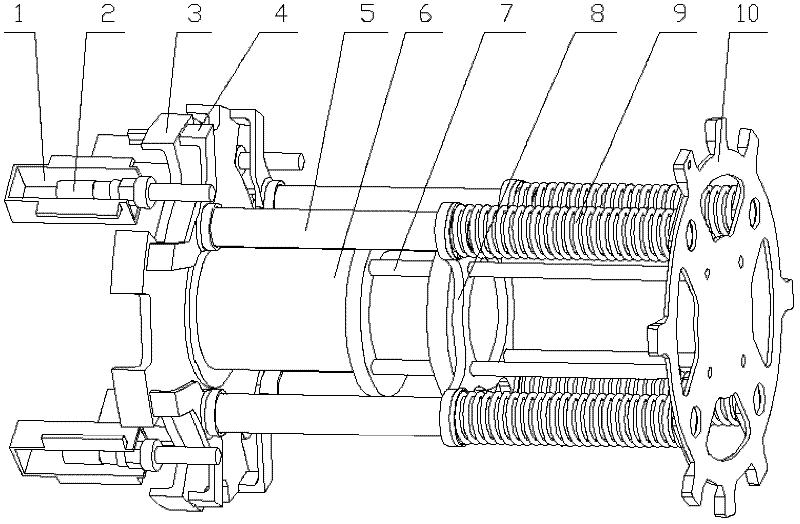

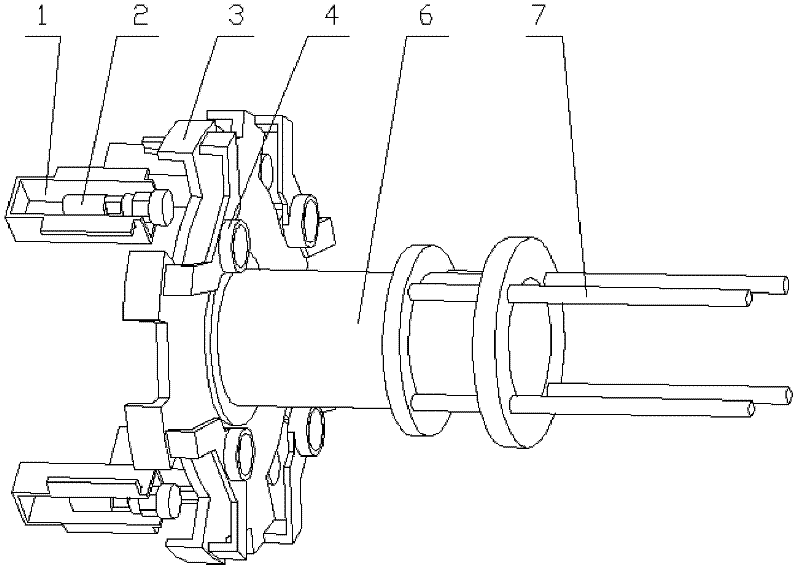

[0021] This embodiment includes: a protective box 1, an explosion bolt 2, a mounting plate 3, a lug 4, a spring guide rod 5, a top cylinder 6, a guide rod 7, a top plate 8, a compression spring 9, and a bottom plate 10.

[0022] One end of the top cylinder 6 is fixedly connected to the middle part of the mounting plate 3, and the other end is a structure of two bosses; 4 guide rods 7 pass through the through holes of the bosses at the end and are fixedly connected to another boss; on the top plate 8 On the spring guide rod 5, one end of the compression spring 9 is provided with a top plate 8, and the four top plates 8 are clamped on the end boss of the top cylinder 6 after pressing the four compression springs; the four guide rods 7 are distributed at equal distances on the circumference of the boss.

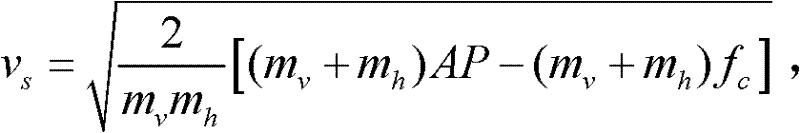

[0023] Spring force P of the 4 compression springs in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com