A processing circuit of a photoelectric liquid level meter

A technology for processing circuits and liquid level gauges. It is applied in instruments, liquid level indicators, engine lubrication, etc. It can solve the problems of uncertain logic judgment, jumping of data level gauges, affecting instrument work detection, etc., to reduce harshness. Requirement and process cost, the effect of improving data processing capacity and reducing maintenance labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

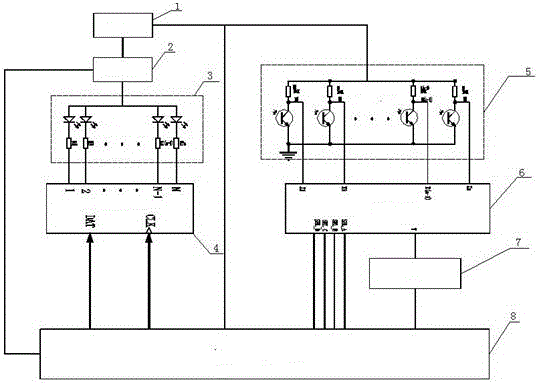

[0016] Such as figure 1 As shown, the power supply 1 is connected to the adjustable power supply 2, the infrared receiving tube array 5 and the processor 8, and the power supply 1 converts the wide voltage input of the external power supply into a voltage of 3.3V to supply power to the entire circuit.

[0017] The adjustable power supply 2 is an adjustable voltage output type, which is connected to the power supply 1, the infrared light emitting tube array 3 and the processor 8. The input voltage of the adjustable power supply 2 is provided by the power supply 1, and the adjustable power supply 2 is connected to the infrared light emitting tube array The output voltage of 3 is controlled by the processor 8, and its output voltage can adjust the luminous intensity of the infrared luminous tubes in the infrared luminous tube array 3.

[0018] The output terminal of the luminous tube control unit 4 is connected to each branch of the input terminal of the infrared luminous tube a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com