Air tightness detecting device and implementation method for same

A technology of air tightness detection and implementation method, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems of inconvenient paint bucket sampling inspection, large volume, and inconvenient movement. , to achieve the effect of reducing material cost, low cost and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

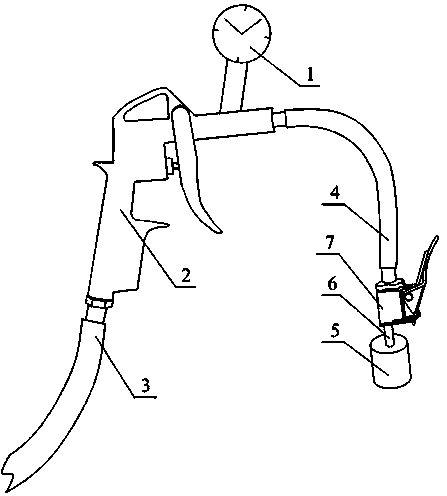

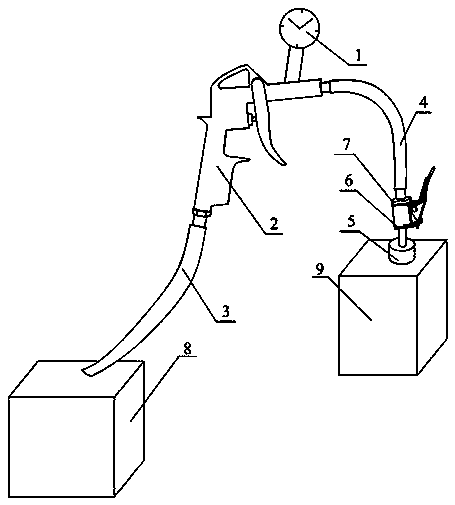

[0029] Such as figure 1 , 2 As shown, the present invention is mainly composed of an air guiding device, which includes an air gun 2, and the air gun 2 has an air inlet end and an air outlet end. In order to facilitate the introduction of compressed air into the air gun 2 , an air intake pipe 3 is provided at the air intake end of the air gun 2 . The air intake pipe 3 is a plastic pipe made of plastic material, so that the air intake pipe 3 is light in weight and easy to move. Air leakage will cause errors in the results of air tightness testing. Simultaneously, the air outlet end of the air gun 2 is then provided with an air guide tube 4 , the overall structure of the air guide tube 4 is the same as that of the air intake pipe 3 , and it is made of the same plastic material as the air intake pipe 3 .

[0030] In order to facilitate the detection of air tightness, a tester 1 is also provided on the air gun 2, the tester 1 is arranged at the gas outlet end of the air gun 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com