High temperature superconducting motor magnet performance test device

A technology of high-temperature superconductivity and test equipment, which is applied in the direction of magnetic performance measurement, measurement equipment, and measurement of electrical variables, to achieve the effects of improving cooling efficiency, convenient installation and wiring of magnets, and authentic and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

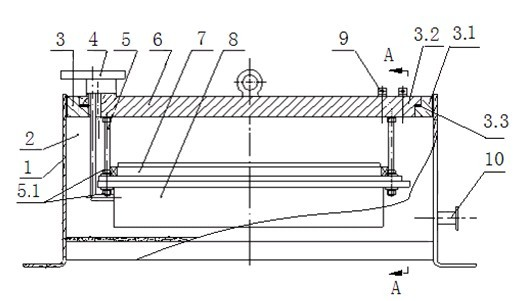

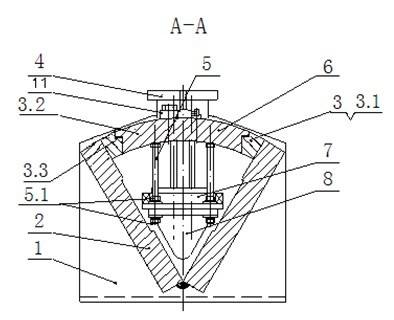

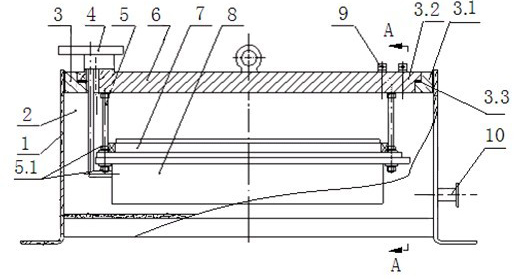

[0022] A high-temperature superconducting motor magnet performance test device, including a magnetically conductive side plate 2 and a magnetically conductive arc top plate 3; the two magnetically conductive side plates 2 form a "V"-shaped angle, and form a magnetically conductive circuit with the magnetically conductive arc top plate 3 ; The magnetic side plate 2, the magnetic arc top plate 3 and the stainless steel end plates 1 at both ends constitute a vacuum container; the stainless steel end plate 1 has a vacuum interface 10; the vacuum container is provided with a heat exchanger 8, the The heat exchanger 8 is connected to the magnetically conductive circular arc top plate 3 through the heat insulating stud 5; the magnetically conductive circular arc top plate 3 is provided with a refrigerant inlet and outlet interface 4 communicating with the refrigerant container or the refrigerator. The magnetically conductive circular arc top plate 3 is composed of a fixed top plate 3....

Embodiment 2

[0024] The difference from the above-mentioned embodiment 1 is that, in the high-temperature superconducting motor magnet performance test device, the refrigerant inlet and outlet ports 4 communicate with the refrigerant container or refrigerator through pipelines. The magnetically permeable side plate 2 is formed by welding two magnetically permeable side plates through the lower part to form a "V" shape structure, or one magnetically permeable side plate is integrally molded into a "V" shaped corner. The magnetically permeable side plate 2, the "V"-shaped corner and the magnetically permeable arc top plate 3 constitute the boundary conditions of the magnetic field, form a magnetically permeable circuit, and simultaneously become a part of the vacuum container shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com