Optical fiber tray

A technology of optical fiber reel and pumping light, which is applied in the field of optical fiber reel, can solve the problems of unfavorable fiber extraction, poor heat dissipation, and inability to maintain, and achieve the effects of convenient long-term stable operation, simple coiling work, compact and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

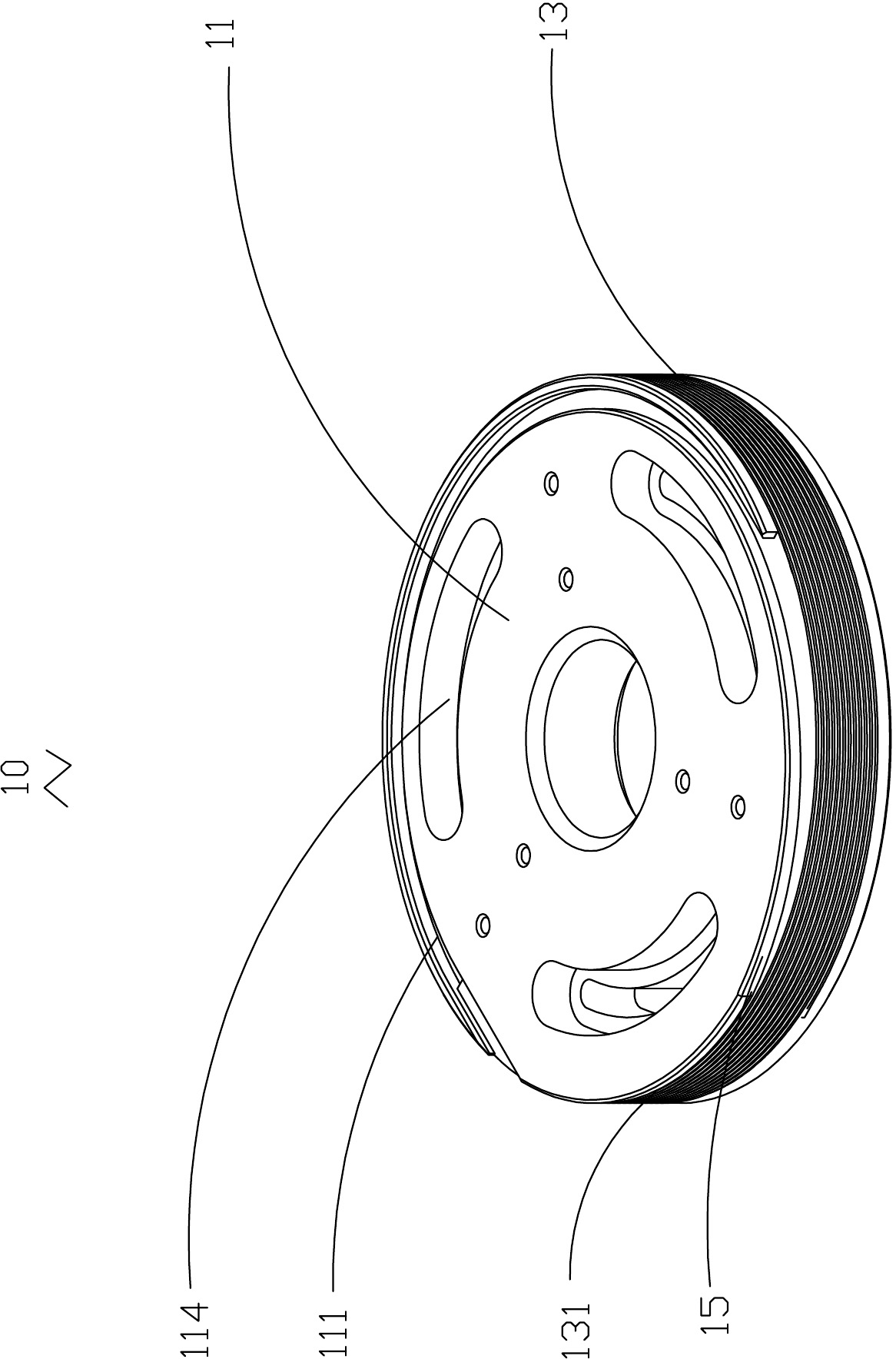

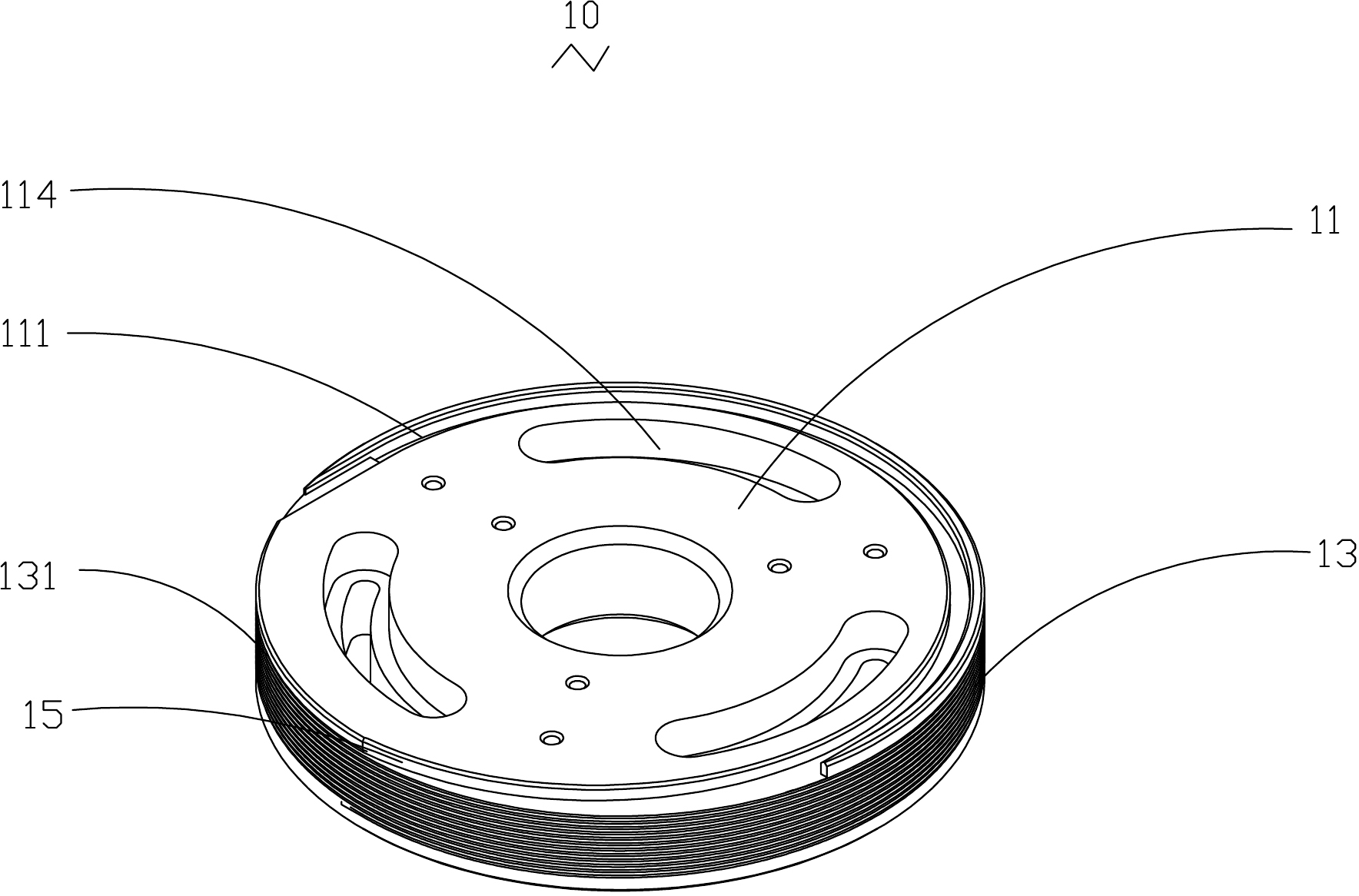

[0014] see figure 1 , the present invention provides an optical fiber reel 10 for coiling optical fibers (not shown). The optical fiber tray 10 includes a top surface 11 and a cylindrical surface 13 connected to the top surface 11, and further includes a separation groove 131 surrounding the cylindrical surface 13, an arc-shaped groove 111 arranged on the edge of the top surface 11, and an arc-shaped groove 111 connected to the top surface 11. The transition groove 15 between the separation groove 131 , the transition groove 15 makes the arc groove 111 and the separation groove 131 smoothly connected.

[0015] In this embodiment, the optical fiber tray 10 is made of aluminum alloy or copper with excellent thermal conductivity.

[0016] In this embodiment, the separation groove 131 is a rectangular threaded groove. It can be understood that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com