Filter tip stick and preparation method thereof

A filter rod and modification technology, which is applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of incompatibility with global sustainable development and domestic national conditions, poor filtration performance of filter rods, and degradation cycle of more than 4 years, etc. The effect of energy crisis, long degradation cycle and solvent environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

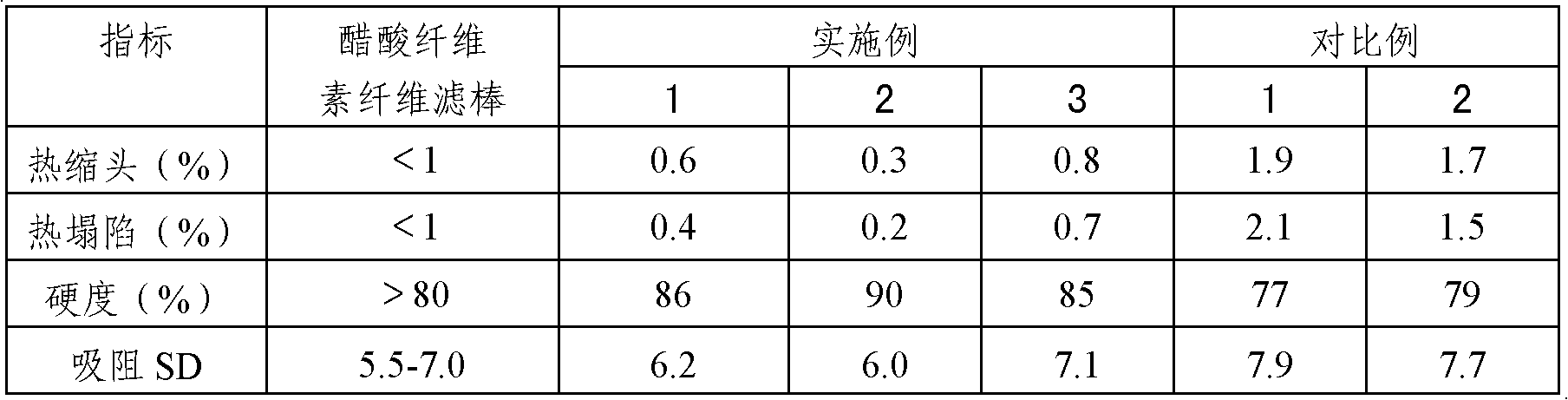

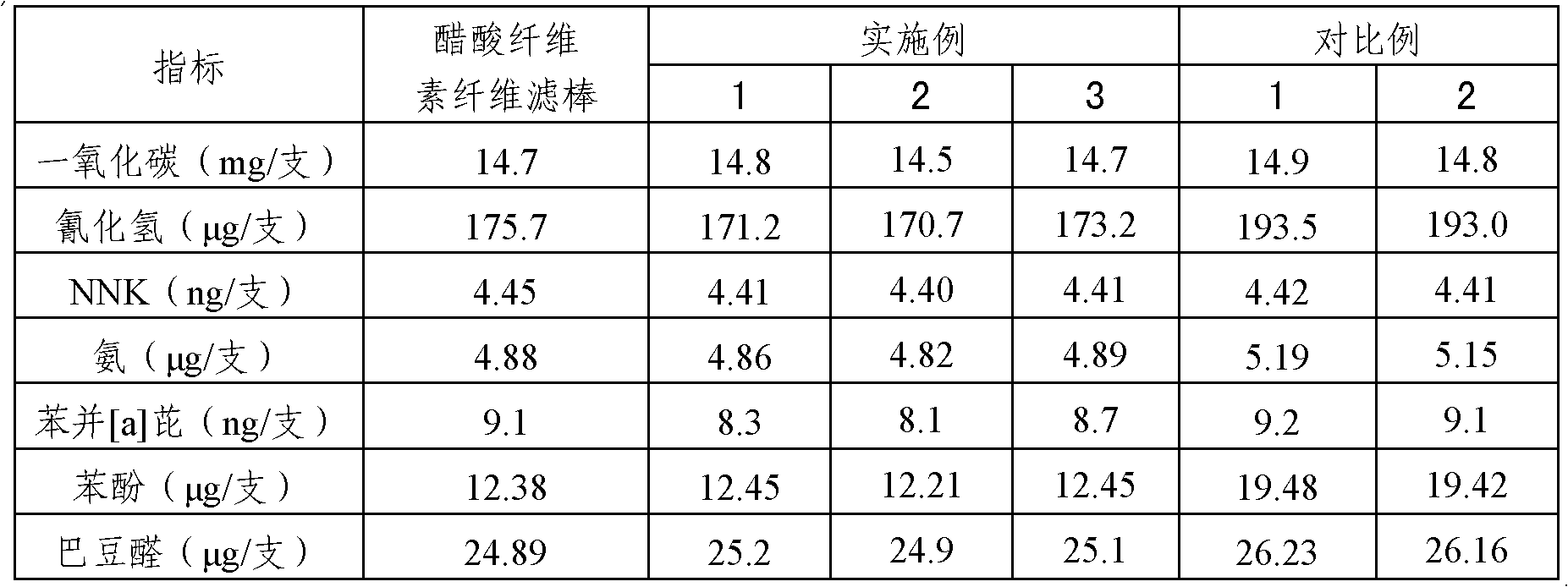

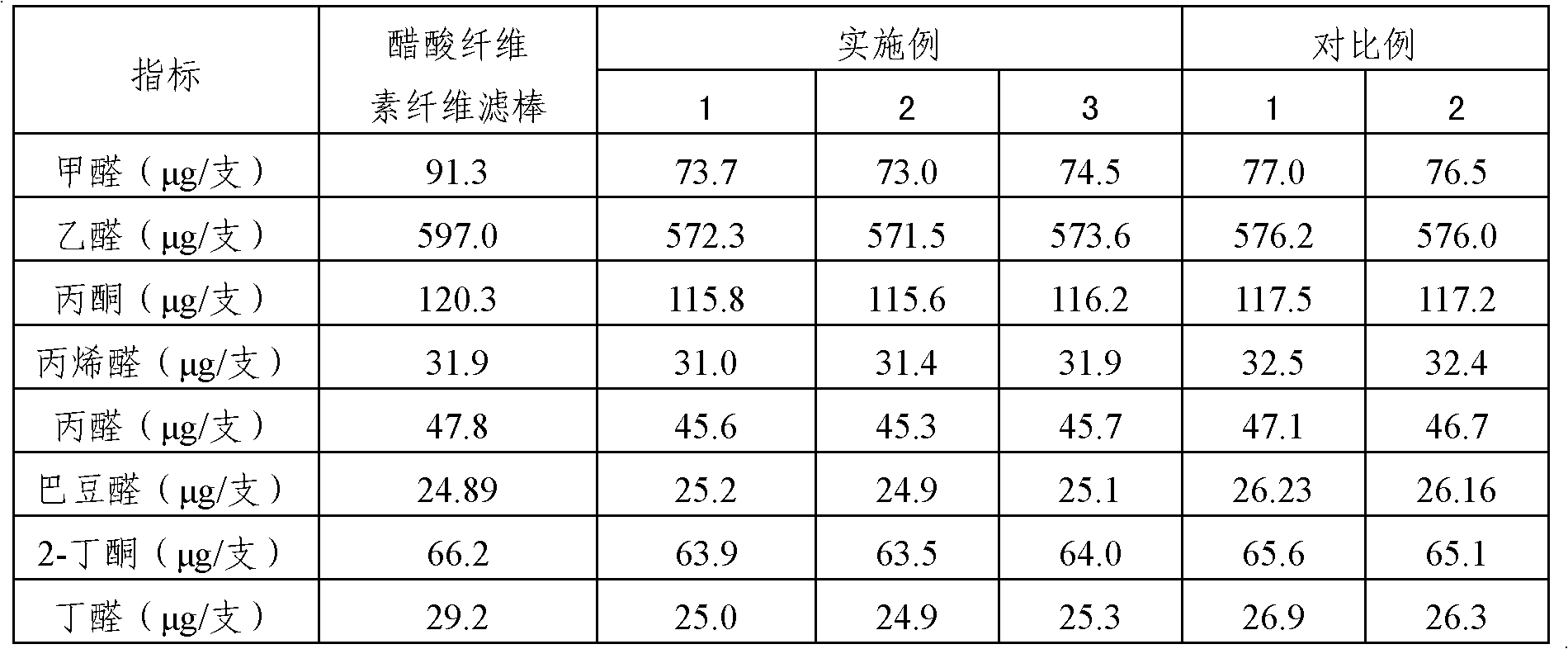

Examples

Embodiment 1

[0050] Example 1: Filter sticks

[0051] 1. Raw materials of modified polylactic acid for spinning include: 98.6 kg of polylactic acid, 0.1 kg of modified porous starch, 1.0 kg of nano-silicon dioxide, and 0.3 kg of nano-titanium dioxide.

[0052] 2. Preparation method:

[0053] 1) Preparation of tow: First weigh 98.6 kg of polylactic acid, 0.1 kg of modified porous starch, 1.0 kg of nano-silicon dioxide, and 0.3 kg of nano-titanium dioxide, and then obtain modified polylactic acid particles through twin-screw melt granulation, and process The temperature is 190°C, and then it is prepared into tow, wherein the linear density of single filament is 3.5dtex, the total density of tow is 3.85ktex, and the number of crimps is 26 pieces / 25mm;

[0054] 2) Extraction: Opening is carried out on the ZL23 filter rod forming machine for filter rod forming. The forming process is: opening ratio 1.35, stable roll pressure 0.05MPa, threaded roll pressure 0.05MPa;

[0055] 3) Sizing:

[005...

Embodiment 2

[0063] Example 2: Filter sticks

[0064] 1. Raw materials of modified polylactic acid for spinning include: 98.4 kg of polylactic acid, 0.7 kg of chitosan, 0.5 kg of nano-silica, and 0.4 kg of nano-titanium dioxide.

[0065] 2. Preparation method:

[0066] 1) Preparation of tow: First weigh 98.4 kg of polylactic acid, 0.7 kg of chitosan, 0.5 kg of nano-silicon dioxide, and 0.4 kg of nano-titanium dioxide, and then obtain modified polylactic acid particles by twin-screw melting granulation. The temperature is 185°C, and then made into tow, the monofilament linear density of the obtained tow is 3.2dtex, the total density of the tow is 4.16ktex, and the number of crimps is 25 / 25mm;

[0067] 2) Extraction: Opening is carried out on the ZL23 filter rod forming machine for filter rod forming. The forming process is: opening ratio 1.30, stable roll pressure 0.05MPa, threaded roll pressure 0.05MPa;

[0068] 3) Sizing:

[0069] First, 0.1 kilogram of soluble calcium phosphate, 0.5 k...

Embodiment 3

[0076] Example 3: Filter sticks

[0077] 1. Raw materials of modified polylactic acid for spinning include: 98.9 kg of polylactic acid, 0.7 kg of chitosan, and 0.4 kg of nano-titanium dioxide.

[0078] 2. Preparation method:

[0079] 1) Preparation of tow: First, 98.9 kg of polylactic acid, 0.7 kg of chitosan and 0.4 kg of nano-titanium dioxide were mixed through twin-screw melt granulation to obtain modified polylactic acid particles. The processing temperature was 195 ° C, and then made into tow. The monofilament linear density of the obtained tow was 3.2dtex, the overall density of the tow was 4.16ktex, and the number of crimps was 25 / 25mm.

[0080] 2) Extraction: Opening is carried out on the ZL23 filter rod forming machine for filter rod forming. The forming process is: opening ratio 1.30, stable roll pressure 0.05MPa, threaded roll pressure 0.05MPa;

[0081] 3) Sizing:

[0082] First 0.5 kilograms of sodium pyrrolidone carboxylate and 0.2 kilograms of citric acid are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com