Silica gel regeneration device

A regeneration device, silica gel technology, applied in filter regeneration, silicon compounds, inorganic chemistry, etc., can solve the problems of reducing recovery rate, colloidal particle explosion, etc., and achieve the effect of eliminating waste, small warm flushing, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

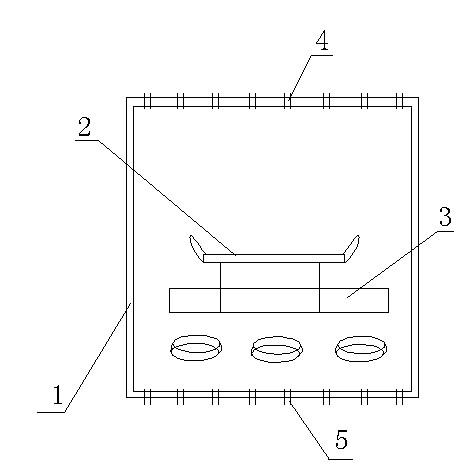

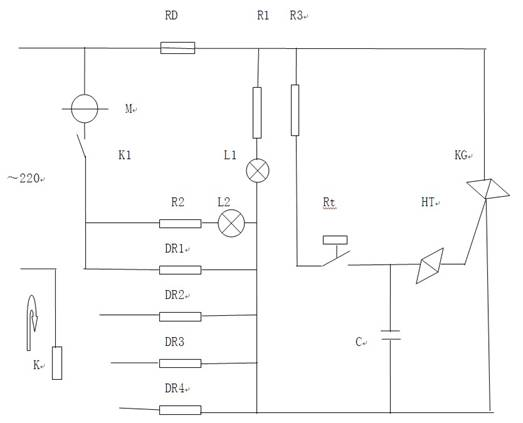

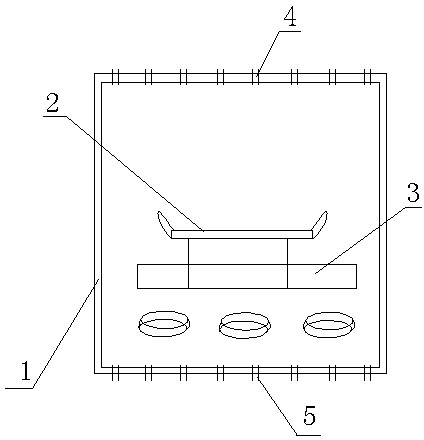

[0014] Such as figure 1 , figure 2 As shown, a silica gel regeneration device includes a drying box 1 with an open door and a silica gel storage tray 2 arranged in the drying box 1. The inner surface of the drying box is provided with a heat insulation layer, the bottom is provided with an air inlet, and the top is provided with a The air outlet and the lower part of the silica gel storage tray are provided with a heating mechanism. A temperature adjustment mechanism is arranged on the heating mechanism. A blowing mechanism is arranged on the heating mechanism. The drying box adopts a convection ventilation structure. The cold air enters from the air inlet hole at the bottom. After being heated by the bottom heater, it enters the drying room. The electric blower promotes the mechanical convection of the indoor hot air to make the indoor temperature uniform. The silica gel is placed on the stainless steel Inside the paper tray, it is evenly heated (the temperature is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com