Preparation method of Fe3+ and N co-doping titanium dioxide fiber porous membrane

A technology of titanium dioxide and porous membrane, which is applied in the field of photocatalyst preparation, can solve problems such as inability to spin, and achieve the effects of easy separation and recovery, simple process, and high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

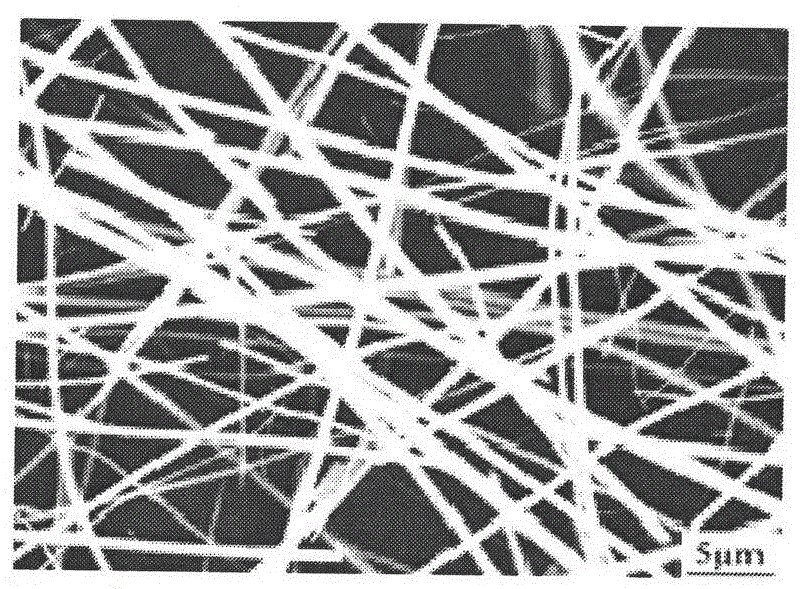

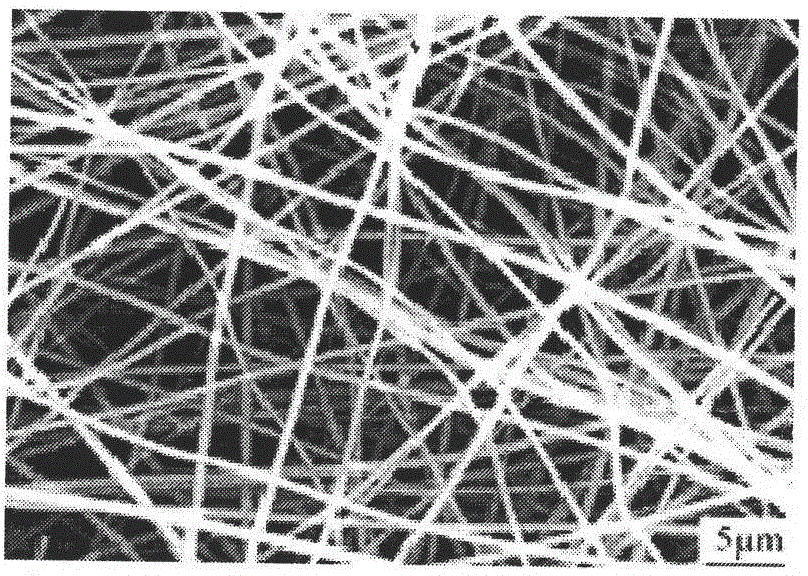

[0026] This embodiment Fe 3+ , N co-doped titania fiber porous membrane and Fe 3+ , N co-doped TiO 2 The photocatalytic degradation of methylene blue by the fiber porous membrane is achieved through the following steps:

[0027] Step 1: Fe(NO 3 ) 3 9H 2 Preparation of O-doped Ti Precursor Fibrous Porous Membrane

[0028] a. Preparation of electrospinning solution: Weigh 3g of tetra-n-butyl titanate, mix with 3mL of glacial acetic acid and 3mL of ethanol, then add Fe(NO 3 ) 3 9H 2 O. After stirring for 30 minutes, add 3 mL of polyvinylpyrrolidone in ethanol solution (containing 0.6 g of polyvinylpyrrolidone), and continue stirring for 1 day to obtain an electrospinning solution.

[0029] b.Fe(NO 3 ) 3 9H 2 Preparation of O-doped titanium precursor fiber porous membrane: The obtained spinning solution was poured into a 20 mL syringe for electrospinning, and the syringe was connected with a stainless steel needle with an inner diameter of 0.7 mm. Then the positive po...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is the third step, and other steps and parameters are the same as those of the first embodiment.

[0037] The third step is: Fe 3+ , N co-doped TiO 2 Solar Photocatalytic Degradation of Printing and Dyeing Wastewater with Fibrous Porous Membrane

[0038] Add 100ml of waste water into the beaker, first measure its pH value, adjust the pH to the required value with dilute glacial acetic acid and sodium hydroxide solution, then add 100mg of Fe into the beaker containing waste water 3+ , N co-doped TiO 2 After the fiber porous membrane was degraded under sunlight (moderately weak ultraviolet rays) for 3 hours, the catalyst was taken out from the beaker, and the wastewater after catalytic degradation was centrifuged, and the absorbance and COD value were tested respectively.

Embodiment 3

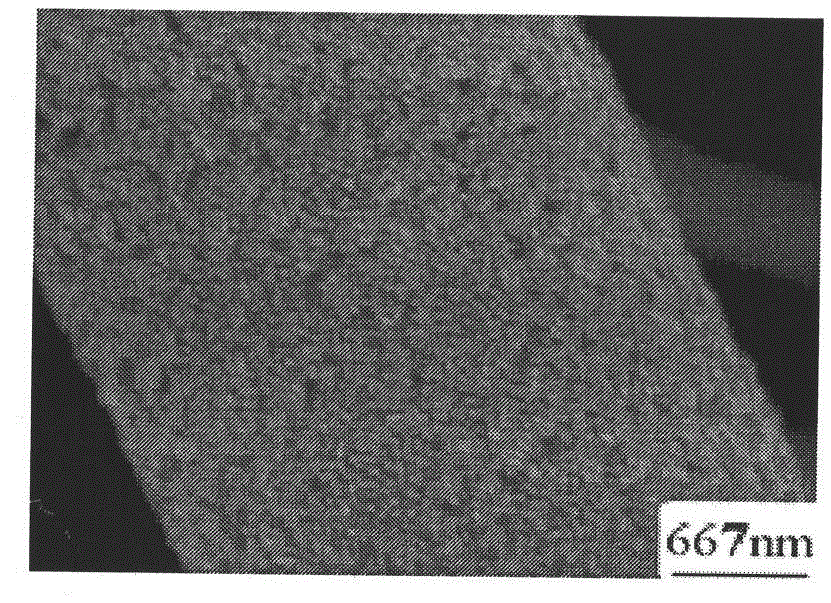

[0040] For different doping amounts of Fe 3+ , N fiber membranes were prepared and their properties were tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com